Aluminum Circle Spinning Quality 88-1000mm Diameter 1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Circle Spinning Quality Description

• Product: Aluminim Circle

• Application: It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

• Advantage: Deep drawing and hard anodizing quality Aluminum Circle Sheet can be supplied. Our Aluminum Circle is RoHS and REACH compliance and uses well-protected packing. Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

2.Main Features of the Aluminium Circle Spinning Quality

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

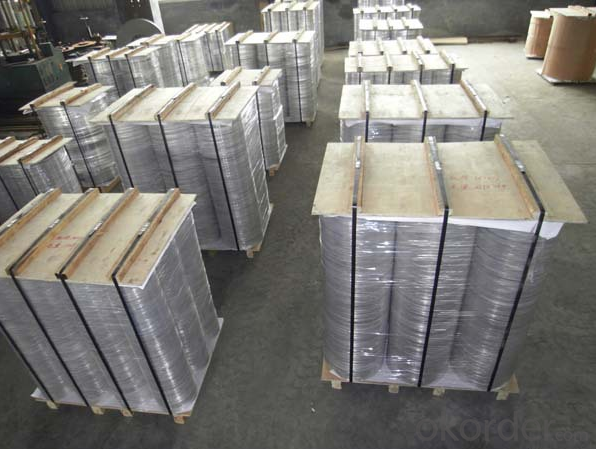

3. Aluminium Circle Spinning Quality Images

4. Aluminium Circle Spinning Quality Specification

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ of Aluminium Circle Spinning Quality

We have organized several common questions for our clients,may help you sincerely:

(1).How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

(2).Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

(3).What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: How can we improve the efficiency and effectiveness of aluminum recycling?

- <p>Yes, there are several ways to recycle aluminum more efficiently and effectively. First, increase consumer awareness about the benefits of recycling aluminum and the importance of proper sorting. Second, invest in advanced recycling technologies that can process aluminum more quickly and with less waste. Third, collaborate with manufacturers to design products that are easier to recycle and made from more recycled content. Lastly, improve collection systems to ensure a higher percentage of aluminum waste is captured and recycled. These steps can significantly boost aluminum recycling rates and sustainability.</p>

- Q: Is it safe or permissible to use aluminum in food packaging materials?

- <p>Yes, aluminum is commonly used in food packaging due to its lightweight, durability, and excellent barrier properties against air, moisture, and light. It is used in various forms such as aluminum foil, cans, and flexible packaging materials. However, it's important to ensure that the aluminum packaging is food-grade and complies with safety regulations to prevent any potential health risks associated with aluminum exposure.</p>

- Q: Explain how the addition of zinc impacts the corrosion resistance of aluminum alloys.

- <p>The addition of zinc to aluminum alloys significantly enhances their corrosion resistance. Zinc forms a protective layer on the surface of aluminum, which prevents the metal from reacting with corrosive elements such as oxygen and moisture. This protective layer, known as a passive layer, is self-healing and can regenerate if damaged, maintaining its effectiveness over time. Additionally, zinc's presence in aluminum alloys can improve the alloy's overall mechanical properties, making it more resistant to stress corrosion cracking. This is particularly useful in marine environments or other corrosive conditions where aluminum alloys are commonly used.</p>

- Q: This question asks about the methods used to determine the hardness of aluminum material.

- <p>The hardness of aluminum can be measured using various standardized tests. The most common methods include the Brinell Hardness Test, where a hard steel or carbide ball is pressed into the aluminum surface, and the Vickers Hardness Test, which uses a diamond pyramid indenter. The Rockwell Hardness Test is also used, applying a diamond cone or steel ball to the surface. The hardness is quantified by the depth of the indentation, and the results are expressed in specific hardness units like BHN (Brinell Hardness Number), HV (Vickers Hardness), or HR (Rockwell Hardness). These tests provide a measure of the material's resistance to deformation, which is crucial for applications requiring strength and durability.</p>

- Q: Is it possible to recycle aluminum and what are the benefits of doing so?

- <p>Yes, aluminum can be recycled, and it is one of the most recycled materials in the world. Recycling aluminum saves up to 95% of the energy needed to produce new aluminum from raw materials. It also reduces greenhouse gas emissions and conserves natural resources. Recycled aluminum can be used in various applications, from beverage cans to construction materials, making it an environmentally friendly and economical choice.</p>

- Q: What measures should be taken to ensure safety while working with aluminum?

- <p>When working with aluminum, it's important to follow safety precautions. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to prevent inhalation of aluminum dust. Ensure good ventilation to avoid the buildup of fumes. Use proper tools and equipment to handle aluminum, as it can become sharp and cause cuts. Be cautious of the heat generated during cutting or welding, as aluminum conducts heat quickly and can cause burns. Store aluminum in a dry place to prevent it from reacting with moisture, which can cause it to corrode. Lastly, be aware of the fire hazard associated with aluminum dust and take necessary fire prevention measures.</p>

- Q: Angell doors and windows as a door brand, compared to other aluminum alloy doors and windows what are the advantages?

- Patterns, products, services have advantages, you can go to their official website to see.

- Q: This question asks about the typical applications of aluminum pipes in various industries and settings.

- <p>Aluminum pipes are commonly used in a variety of applications due to their lightweight, corrosion resistance, and high thermal conductivity. They are extensively used in the automotive industry for parts like radiators and heat exchangers. In construction, aluminum pipes are utilized for heating, ventilation, and air conditioning (HVAC) systems. They are also used in the beverage industry for conveying and cooling liquids, as well as in the aerospace industry for fuel and hydraulic lines due to their strength-to-weight ratio. Additionally, aluminum pipes are found in industrial settings for compressed air and gas lines, and in marine applications for fuel and water systems.</p>

- Q: Dangemen mills and other Aluminum Alloy and enterprises what is the difference?

- Other aluminium door enterprises cover many other products. This can be said to be the most obvious difference Dangemen factory and other enterprises.

- Q: Is it safe to utilize aluminum cookware in a microwave oven, considering potential hazards or damage?

- <p>Using aluminum pots and pans in a microwave oven is not recommended. Aluminum can cause sparks and potentially start a fire, as microwaves can reflect off metal surfaces and damage the microwave. Additionally, aluminum may not distribute heat evenly, leading to uneven cooking. It's safer to use microwave-safe cookware, such as glass or ceramic dishes, which are designed to withstand microwave heating without risk.</p>

Send your message to us

Aluminum Circle Spinning Quality 88-1000mm Diameter 1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches