Aluminum AA1100 Mill Finished Aluminum Circles CC Quality for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware Description

AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware is made from aluminum coils 1xxx. AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

2. Main features of AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware

a.We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.We can control the delivery time within 35 days.

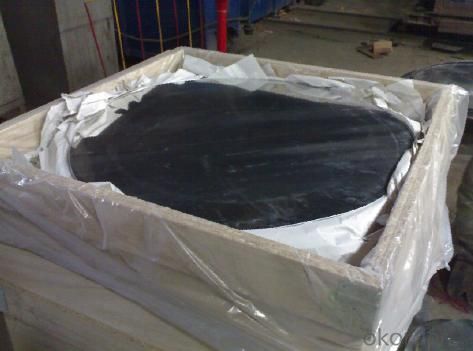

3. AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware Images

4. AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware Specification

Alloy | AA1100 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: This question asks about the various uses of aluminum in the electronics industry.

- <p>Aluminum is widely used in electronics for several applications due to its excellent electrical conductivity, lightweight, and corrosion resistance. It's commonly used in the manufacturing of electrical wires and cables, as it efficiently conducts electricity. Aluminum is also utilized in heat sinks and heat dissipation systems to manage heat generated by electronic components. Furthermore, it's employed in the construction of electronic casings and enclosures for its strength and lightweight properties. Additionally, aluminum is used in electrolytic capacitors and as a reflective coating in some types of electronic displays. Its versatility makes it indispensable in various electronic devices, from computers to smartphones and other consumer electronics.</p>

- Q: Is it possible to utilize recycled aluminum for the production of jewelry and fashion accessories?

- <p>Yes, recycled aluminum can be used to make jewelry and other fashion accessories. Recycled aluminum is a sustainable and cost-effective alternative to new aluminum, and it maintains the same properties as newly mined aluminum. It is lightweight, durable, and can be easily molded into various shapes and designs. Many fashion designers and jewelers are increasingly using recycled aluminum to create unique and eco-friendly products, reducing the environmental impact of their creations.</p>

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a roofing material.

- <p>Advantages of using aluminum sheets for roofing include their lightweight nature, which reduces structural load; corrosion resistance, making them suitable for coastal areas; and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Disadvantages include the potential for dents and damage from hail or heavy impacts, and they can be more expensive than some other roofing materials. Additionally, aluminum can be noisy during rain, and it may require more frequent replacement compared to some other materials due to its lighter gauge.</p>

- Q: This question asks about the environmental impact of aluminum foil, including its production, usage, and disposal.

- <p>Aluminum foil has a significant environmental impact. Its production requires large amounts of energy, contributing to greenhouse gas emissions. The mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Additionally, improper disposal of aluminum foil contributes to littering and can end up in landfills, where it takes centuries to decompose. However, aluminum is also highly recyclable, and recycling reduces energy consumption and emissions. Efforts to reduce aluminum foil usage and increase recycling are crucial for mitigating its environmental impact.</p>

- Q: This question asks about the health effects of consuming aluminum on human health.

- <p>Aluminum consumption can have various effects on human health, though the extent of its impact is still a subject of debate among researchers. High levels of aluminum intake have been associated with neurological disorders, particularly Alzheimer's disease, although a direct causal link has not been definitively established. Aluminum can also interfere with bone health, potentially leading to osteoporosis, and may affect the kidneys, causing dysfunction. It is important to note that the human body naturally excretes aluminum, so moderate exposure is generally not harmful. However, excessive intake, especially over a long period, could pose health risks.</p>

- Q: Is it possible to create jewelry using aluminum as the primary material?

- <p>Yes, aluminum can be used to make jewelry. It is a lightweight, durable, and affordable metal that is often used in costume jewelry and fashion accessories. Aluminum's low cost and ease of shaping make it a popular choice for designers looking for a versatile material that can mimic the look of more expensive metals. However, it is not as strong or valuable as precious metals like gold or silver, and it may not be suitable for fine jewelry due to its lower durability and potential for oxidation.</p>

- Q: Is it possible to use pure aluminum for crafting jewelry or sculptures?

- <p>Yes, you can use pure aluminum for jewelry making or sculpture, but it's not as common as other metals due to its lower melting point and softer nature. Pure aluminum is lightweight, affordable, and easy to work with, making it suitable for certain types of designs. However, it's not as durable or resistant to scratches as metals like silver or gold, and it may require special care to maintain its appearance. It's also important to consider the potential for allergic reactions, as some people are sensitive to aluminum.</p>

- Q: Describe the reaction between aluminum and oxygen, including the product formed.

- <p>Aluminum reacts with oxygen to form aluminum oxide (Al2O3). This reaction is an oxidation process where aluminum loses electrons and oxygen gains them. The reaction can be represented by the equation: 4Al + 3O2 鈫?2Al2O3. Aluminum oxide forms a protective layer on the surface of aluminum, preventing further oxidation. This property makes aluminum a corrosion-resistant metal, despite its reactivity with oxygen.</p>

- Q: Is there an alternative method for recycling aluminum besides the conventional process?

- <p>Yes, aluminum can be recycled using different processes. While the conventional process involves melting and recasting, alternative methods include mechanical recycling, which involves shredding and reusing aluminum without melting, and chemical recycling, which breaks down aluminum into its base elements and reassembles them into new products. These methods can be more energy-efficient and environmentally friendly, depending on the specific circumstances and technologies used.</p>

- Q: This question asks about the steps involved in preparing aluminum foil for use in food packaging.

- <p>Aluminum foil for food packaging is processed through several steps. First, aluminum ingots are melted and then rolled into thin sheets. The sheets are cleaned to remove any impurities and coated with a thin layer of food-grade protective coating to prevent any chemical reactions with the food. Next, the sheets are cut into rolls or sheets of standard sizes. The aluminum foil is then inspected for quality, ensuring it is free from defects and safe for food contact. Finally, it is packaged and shipped to manufacturers who use it to wrap or package food products.</p>

Send your message to us

Aluminum AA1100 Mill Finished Aluminum Circles CC Quality for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches