Aluminum Sheets in Arizona - Aluminium Profile with Sand Blasting Treatment SA6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Profile with Sand Blasting Treatment SA6 Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of theAluminium Profile with Sand Blasting Treatment SA6:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

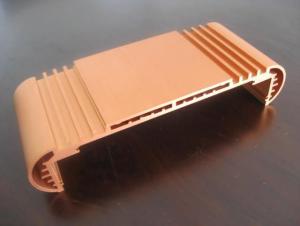

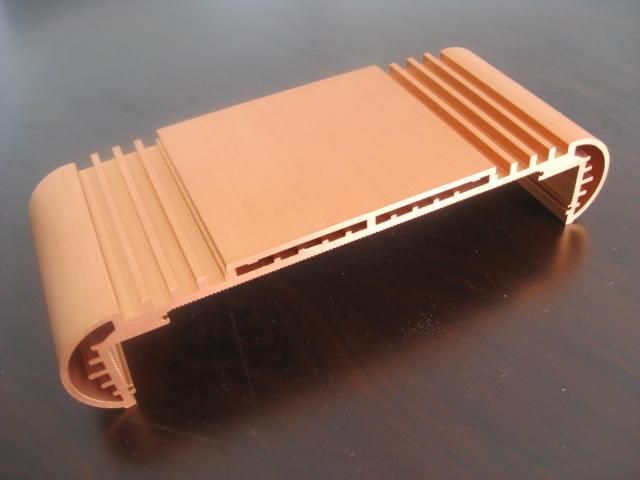

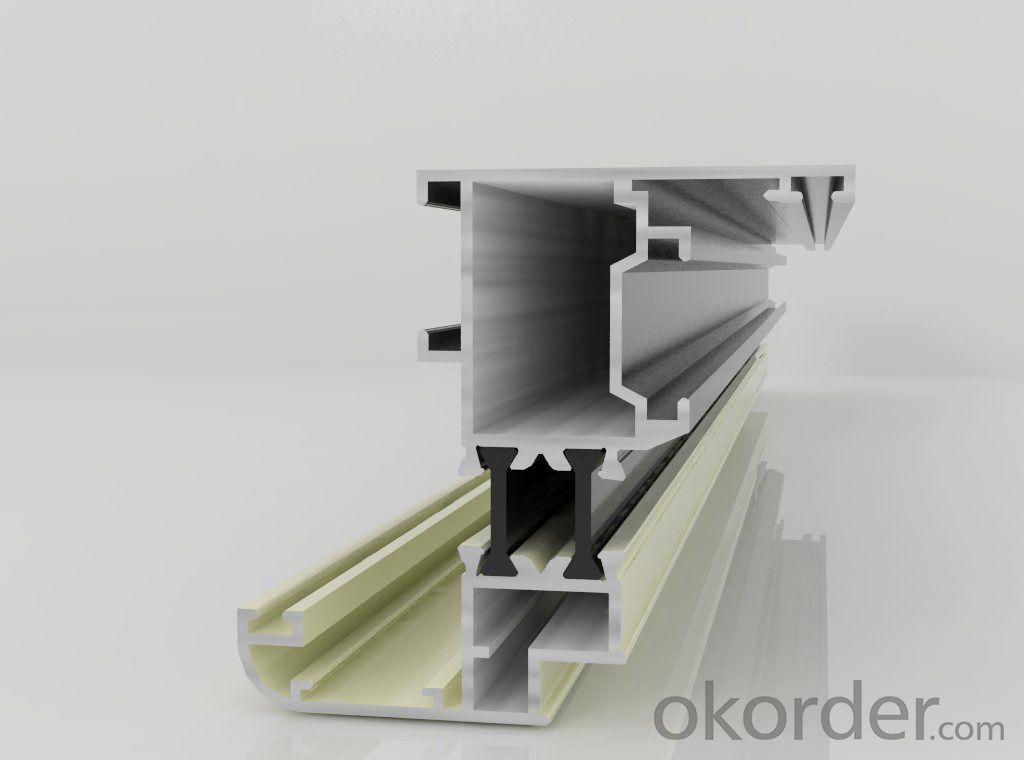

3.Aluminium Profile with Sand Blasting Treatment SA6 Images:

4.Aluminium Profile with Sand Blasting Treatment SA6 Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has high thermal conductivity, which means it can effectively absorb and distribute heat, making it an excellent material for heat protection. It is commonly used in various applications such as automotive, aerospace, and industrial settings to shield sensitive components from high temperatures.

- Q: Are aluminum sheets suitable for automotive wheels?

- Yes, aluminum sheets are suitable for automotive wheels. Aluminum is a lightweight and durable material that offers several advantages for automotive applications. The use of aluminum wheels can significantly reduce the unsprung weight of a vehicle, resulting in improved fuel efficiency and better handling. Additionally, aluminum has excellent heat dissipation properties, which helps to prevent overheating of the brakes. Aluminum wheels also have a sleek and stylish appearance, making them a popular choice among car enthusiasts. However, it is important to note that not all aluminum sheets are suitable for automotive wheels. The sheets used for wheels need to meet specific requirements in terms of strength, durability, and heat resistance. Therefore, it is crucial to select high-quality aluminum sheets that are specifically designed for automotive wheel applications.

- Q: What are the surface treatment requirements for aluminum sheets in the food industry?

- Aluminum sheets are widely used in the food industry due to their exceptional resistance to corrosion and lightweight nature. However, it is essential to fulfill specific surface treatment criteria to guarantee the safety and quality of the food items. To begin with, aluminum sheets utilized in the food industry must undergo a cleansing process to eliminate impurities and contaminants. This can be achieved through various methods, such as chemical, alkaline, or mechanical cleaning. The objective is to eradicate any potential sources of contamination that could adversely impact the taste, odor, or safety of the food. In addition, it is crucial to properly finish the surface of the aluminum sheets to prevent any interaction between the metal and the food. Anodizing is a highly favored surface treatment technique that forms a protective oxide layer on the aluminum surface. This layer not only enhances corrosion resistance but also acts as a barrier against the migration of aluminum ions into the food. Moreover, it is of utmost importance to ensure that the materials used for surface treatment are food-grade and compliant with relevant regulations. The food industry has implemented specific guidelines and standards to ensure the safety and suitability of materials that come into contact with food. Therefore, adherence to these standards is essential during the surface treatment process to prevent any potential health hazards or risks of contamination. Regular inspection and maintenance of the surface treatment are also necessary to ensure its long-lasting effectiveness. This involves monitoring the integrity of the protective layer, identifying any signs of wear or damage, and taking prompt corrective actions. To summarize, the requirements for surface treatment of aluminum sheets in the food industry encompass thorough cleansing, proper finishing, the use of food-grade materials, and regular maintenance. These measures are critical in ensuring the safety and quality of food products, as well as compliance with industry regulations and standards.

- Q: Can 101 aluminum sheets be anodized for medical equipment applications?

- Medical equipment applications can involve anodizing 101 aluminum sheets, which creates a protective layer on the surface of the aluminum. This process enhances corrosion resistance, durability, and the overall aesthetic appearance. Anodizing is commonly used in the medical industry to improve equipment performance and longevity, as well as to maintain cleanliness and sterility. The specific alloy, such as 101, does not typically affect the anodizing process, as it can be applied to various grades of aluminum. However, it is crucial to consult with an anodizing specialist or manufacturer to ensure that the specific alloy is suitable for the intended medical equipment application and to determine the most appropriate anodizing process and specifications.

- Q: Can aluminum sheets be powder-coated?

- Indeed, aluminum sheets undergo powder coating, a procedure involving the electrostatic application of dry, powdered paint onto a surface. Subsequently, the coated aluminum is subjected to heat curing, resulting in a robust and visually appealing finish. Aluminum is particularly well-suited for powder coating due to its lightweight nature and resistance to corrosion. The powder coating firmly attaches to the aluminum surface, creating a protective layer that enhances the sheet's aesthetic appeal while offering enduring safeguard against deterioration.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and bent without fracturing or cracking. This property makes aluminum an ideal material for various applications, including the manufacturing of aircraft, automobiles, and household items. The flexibility of aluminum sheets allows for the creation of intricate designs and complex shapes, making it a highly versatile material. However, it is important to note that the thickness and grade of the aluminum sheet can influence its bendability. Thicker sheets may require more force and specialized tools to achieve the desired bend, while softer grades of aluminum may be more easily bent.

- Q: Can aluminum sheets be used in automotive applications?

- Aluminum sheets find their utility in automotive applications. This lightweight and sturdy material brings a multitude of advantages to the manufacturing of automobiles. It is widely employed in the creation of car bodies, hoods, doors, roofs, and various other components. By incorporating aluminum sheets into automotive applications, the overall weight of the vehicle can be reduced, thereby enhancing both fuel efficiency and performance. Moreover, aluminum boasts exceptional resistance to corrosion, making it well-suited for enduring harsh weather conditions and exposure to road salt. Additionally, aluminum can be easily molded and shaped, facilitating intricate designs and detailing on automotive parts. In summary, the utilization of aluminum sheets in automotive applications contributes to the creation of vehicles that are lighter, more fuel-efficient, and visually appealing.

- Q: Could ring-pull can be transformed as aluminum sheet?

- Yes, but the ring-pull cans contains fewer aluminum.

- Q: Can aluminum sheets be used for storage tanks?

- Yes, aluminum sheets can be used for storage tanks. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for storing various substances such as water, chemicals, and fuel. It offers excellent durability and can withstand harsh environmental conditions. Additionally, aluminum tanks are relatively easy to construct and maintain. However, it is important to consider the specific requirements of the substance being stored and consult with experts or engineers to ensure that aluminum sheets are the appropriate choice for the storage tank in question.

- Q: I don't know if the electrons are being passed from my hand to the aluminum or from the aluminum to my hand.Thanks

- Aluminum is a metal and every metal has a property that it holds electrons of its outer most orbital quite loosely ( it is electropositive ). And our hand's skin consists of mostly COVALENT bonded compounds which hold their electrons quite tightly. So if we touch aluminum the chances are strong that the electrons are being transferred from aluminum to our hands. But since our hand have covalent compounds so the total transfer must be very small if it is anyway. Otherwise we feel shock every time we touch a neutral aluminum also IF U develop some negative charge then aluminum will take that charge since it has small hold on the outermost electrons. so it easily takes charge frm yr hand at lower potential to its ground potential surface.

Send your message to us

Aluminum Sheets in Arizona - Aluminium Profile with Sand Blasting Treatment SA6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords