Coil Aluminum Roll - Pre-Painted Aluminum Coil/Sheet Stone Series 1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil/Sheet Stone Pre-painted Serie 1:

Aluminium coil/sheet are of a wide range of specifications, and they are widely used in:Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...Advertisement: display platforms, signboards, fascia, shop fronts...

Main Features of Aluminium Coil/Sheet Stone Pre-painted Serie 1 :

1) High gloss

2) High flexibility

3) Impact resistance

4) Excellent weather-proof durability

5) Anti-ultraviolet

6) High erosion resistance

7) Stable color and gloss

8) Good mechanical processing performance

9) Abrasion resistance

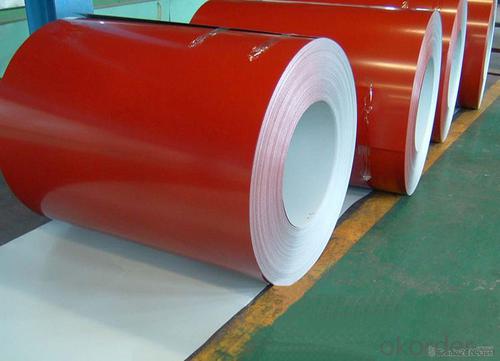

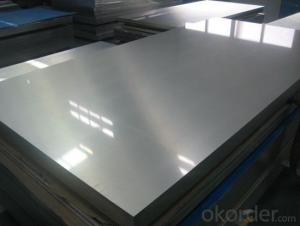

Image of Aluminium Coil/Sheet Stone Pre-painted Serie 1:

Specifications of Aluminium Coil/Sheet Stone Pre-painted Serie 1:

Alloy | A1100,A3003, A8011 etc |

Temper | H16,H18,H26 |

Thickness | 0.02-3.0mm |

Width | Standard width:1200 1240mm |

30mm-1500mm | |

Diameter | Outside dia:1200mm\1000mm\1240 |

Interior dia: 405mm,505mm | |

Weight | 1.5T/coil,2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, |

Surface | Color coated, Embossed, mill finish, |

Color | As to RAL |

Gloss | 10 - 90%(EN ISO-2813:1994) |

Coating Thickness | P E : more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 a.What is monthly capacity |

FAQ of Aluminium Coil/Sheet Stone Pre-painted Serie 1:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be used in the production of heat exchanger fins?

- Yes, aluminum coils can be used in the production of heat exchanger fins.

- Q: What is the difference between hot-rolled and cold-rolled aluminum coils?

- The main difference between hot-rolled and cold-rolled aluminum coils lies in the manufacturing process and the resulting properties of the finished product. Hot-rolled aluminum coils are produced by heating aluminum ingots at high temperatures and then passing them through rollers to achieve the desired thickness and shape. This process makes the aluminum more malleable and allows for greater flexibility in terms of shape and size. Hot-rolled coils are typically larger in size and have a rougher surface finish compared to cold-rolled coils. On the other hand, cold-rolled aluminum coils are manufactured by cooling down the hot-rolled coils and then passing them through rollers at room temperature. This process not only reduces the thickness of the aluminum but also improves its surface finish, making it smoother and more aesthetically pleasing. Cold-rolled coils are typically thinner and have a more consistent thickness compared to hot-rolled coils. The differences in the manufacturing process and surface finish of these two types of coils result in different mechanical properties. Hot-rolled aluminum coils are generally less strong and have lower tensile strength compared to cold-rolled coils. However, hot-rolled coils are more ductile and can be easily formed and shaped without cracking. On the other hand, cold-rolled coils have higher tensile strength and are more suitable for applications requiring greater strength and durability. In summary, hot-rolled aluminum coils are larger, have a rougher surface finish, and are more malleable, while cold-rolled aluminum coils are thinner, have a smoother surface finish, and are stronger. The choice between hot-rolled and cold-rolled coils depends on the specific requirements of the application, such as strength, surface finish, and formability.

- Q: How are aluminum coils processed for specific surface finishes?

- Aluminum coils are processed for specific surface finishes through various methods such as mechanical polishing, chemical etching, anodizing, or coating. These processes help achieve desired appearances, textures, and protective coatings on the aluminum surface.

- Q: If so why does an aluminum bend or get nicked or break quickly?

- NO! You should ask yourself why Tank built with steel rather than using aluminum.

- Q: Can a digital caliper be utilized to accurately measure the diameter of an aluminum coil?

- <p>Yes, you can use a digital caliper to measure the diameter of an aluminum coil accurately. Digital calipers are precise measuring tools, often accurate to 0.001 inches or 0.02mm, which is suitable for measuring the diameter of various objects, including aluminum coils. Ensure the caliper is zeroed before use and that the coil's surface is clean and flat where the measurement is taken to get accurate readings.</p>

- Q: Are aluminum coils suitable for signage applications?

- Signage applications can benefit from the use of aluminum coils. Aluminum, being a highly versatile material, offers several advantages for this purpose. To begin with, aluminum coils are lightweight, making them easy to handle and install. This advantage is particularly beneficial when dealing with large outdoor signs or banners that require mounting or hanging. Moreover, aluminum exhibits a high resistance to corrosion, ensuring the signage remains in good condition even in harsh weather conditions. This durability also makes aluminum coils suitable for long-term outdoor use, as they can withstand exposure to UV rays, moisture, and temperature changes without deteriorating. Additionally, aluminum coils can be easily fabricated and shaped to create various sign designs, including flat panels, channel letters, and dimensional signage. They can be painted or coated with different finishes to achieve the desired aesthetic appearance, making them versatile for branding and marketing purposes. Another advantage of utilizing aluminum coils for signage applications is their recyclability. Aluminum is a sustainable material that can be recycled repeatedly without losing its quality. This makes it an environmentally-friendly choice for businesses that prioritize sustainability and aim to reduce their carbon footprint. In conclusion, due to their lightweight nature, corrosion resistance, durability, versatility in design, and recyclability, aluminum coils are a suitable choice for signage applications.

- Q: How much is one square aluminum gate and five hard door?

- Double layer aluminum alloy, in the middle of the 5 bars, ordinary white or beige is 215, a square, the motor, in addition, the general 600KG copper core motor has 550 sets, there are 680 sets. On the Alibaba website search "roll gate", there are many manufacturers, you can ask them.

- Q: This question asks for an explanation of the various types of coatings that can be applied to aluminum coils.

- <p>Aluminum coils can be coated with several types of materials to enhance their properties for various applications. The main types include: 1. Anodized Coatings: These provide a protective oxide layer on the aluminum surface, enhancing corrosion resistance. 2. PVDF (Polyvinylidene Fluoride) Coatings: Known for their durability and resistance to UV rays, chemicals, and weathering. 3. Polyester Coatings: These are used for general-purpose applications due to their balance of properties like formability and chemical resistance. 4. PVF2 (Polyvinylidene Fluoride) Coatings: Similar to PVDF but with a thinner film, offering good weather resistance. 5. Acrylic Coatings: Known for their flexibility and adhesion, suitable for both interior and exterior applications. 6. Silane Coatings: Provide a thin, protective layer that enhances paint adhesion and corrosion resistance. Each type serves different purposes, and the choice depends on the specific requirements of the application.</p>

- Q: Are aluminum coils fire-resistant?

- Yes, aluminum coils are fire-resistant. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and it does not burn, making it a non-combustible material. This property makes aluminum coils suitable for various applications where fire resistance is a critical factor, such as in building construction, electrical wiring, and HVAC systems. Additionally, aluminum's excellent heat conductivity helps dissipate heat quickly, reducing the risk of fire. However, it is important to note that while aluminum coils themselves are fire-resistant, they may be used in systems that include other components which may not have the same level of fire resistance. It is important to consider the entire system and follow proper fire safety regulations and guidelines to ensure overall fire safety.

- Q: How are aluminum coils used in packaging?

- Aluminum coils are widely used in packaging due to their excellent properties and versatility. These coils are usually made from aluminum alloy, known for its lightweight yet strong characteristics. One common application of aluminum coils in packaging is in the production of aluminum cans. The coils are rolled into thin sheets, which are then formed into cans of various shapes and sizes. The lightweight nature of aluminum makes it ideal for manufacturing cans that are easy to transport and handle, reducing overall packaging weight. Aluminum coils are also used in the production of flexible packaging materials such as foils and laminates. These materials are commonly used for packaging food products, pharmaceuticals, and other perishable goods. The flexibility of aluminum allows it to be easily shaped and formed into different packaging formats, ensuring efficient and convenient use. Another important use of aluminum coils in packaging is in the production of closures and bottle caps. Aluminum closures provide an airtight seal, protecting the contents of the package from external factors such as moisture, contaminants, or oxidation. Additionally, aluminum closures can be easily opened and closed, providing convenience to consumers. Furthermore, aluminum coils are employed in the production of blister packs, which are widely used in the pharmaceutical industry. Blister packs consist of a plastic sheet with aluminum foil lamination, creating a barrier against moisture, light, and oxygen. This packaging format ensures the integrity and safety of pharmaceutical products by protecting them from degradation or contamination. In summary, aluminum coils are extensively used in packaging due to their lightweight, strength, and versatility. These coils are transformed into various packaging formats such as cans, flexible foils, closures, and blister packs, providing durability, protection, and convenience to both manufacturers and consumers.

Send your message to us

Coil Aluminum Roll - Pre-Painted Aluminum Coil/Sheet Stone Series 1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords