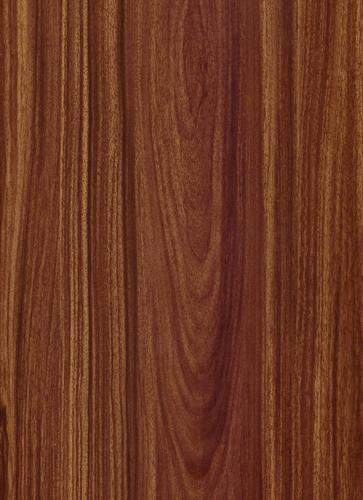

Aluminum Coil Rolling Thailand - Aluminium Coating Coil with Wood Grain

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: This question asks for a comparison between aluminum coil and iron coil, highlighting their distinct properties and uses.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has excellent electrical and thermal conductivity, making it ideal for electrical wiring, heat sinks, and food packaging. Iron coil, on the other hand, is heavier, stronger, and more durable, commonly used in construction, automotive, and heavy machinery due to its high tensile strength. Iron also has magnetic properties, useful in applications like transformers and electromagnets. While aluminum is non-magnetic, it is more cost-effective and has better recyclability compared to iron.</p>

- Q: when ferrous sulfate is poured into an aluminium can, holes appear in the can. Why?

- aluminum reacts via a redox reaction with iron(II): 3 Fe2+(aq) + 2 Al(s) --- 3 Fe(s) + 2 Al3+(aq)

- Q: This question asks for a comparison of various types of equipment used for welding aluminum coils, highlighting their distinct features and applications.

- <p>Aluminum coil welding equipment varies based on technology, power source, and application. TIG (Tungsten Inert Gas) welders are known for high-quality welds and are ideal for thin aluminum coils. MIG (Metal Inert Gas) welders are versatile and suitable for thicker coils, offering faster welding speeds. Stick welders are more portable and cost-effective but produce lower quality welds. Laser welders provide precise, deep penetration welds suitable for high-precision applications. Friction stir welding is a solid-state process that offers excellent joint properties without melting the metal. Each type has its advantages and is chosen based on the specific requirements of the welding task, such as material thickness, weld quality, and production rate.</p>

- Q: Are aluminum coils suitable for use in heating applications?

- <p>Yes, aluminum coils can be used for heating. They are known for their excellent thermal conductivity, which allows for efficient heat transfer. Aluminum's lightweight nature and resistance to corrosion make it a popular choice in various heating applications, such as in electric heating elements, heat exchangers, and cookware. However, it's important to note that aluminum's low melting point means it's not suitable for high-temperature applications and should be used within safe temperature limits to prevent melting or damage.</p>

- Q: Can aluminum coils be used in solar energy systems?

- Certainly, solar energy systems can utilize aluminum coils. Aluminum is widely employed in the fabrication of solar panels and solar energy systems owing to its remarkable qualities. Lightweight, durable, and possessing excellent thermal conductivity, aluminum coils are perfect for dispersing heat away from solar cells. Moreover, aluminum's resistance to corrosion is essential for outdoor deployments, where solar panels face diverse weather conditions. By incorporating aluminum coils into solar energy systems, the efficiency and lifespan of the panels are enhanced, thus augmenting the efficacy and sustainability of solar energy generation.

- Q: What is the maximum width and thickness of aluminum coils?

- The maximum width and thickness of aluminum coils vary depending on the specific grade and manufacturing capabilities. However, as a general guideline, aluminum coils can range in width from a few inches to several feet, while thickness can range from a few millimeters to several inches. It is important to consult the manufacturer or supplier for precise specifications based on the intended application.

- Q: I am confused by that. One guy told me that he puts aluminium foil on his modem to receive the Internet better. Another guy told me that aluminium stops all kind of rays. What is correct?

- BOTH ARE CORRECT.... COVER THE WHOLE WIRELESS MODEM WITH ALUMINUM FOIL AND GROUND IT SHALL BLOCK ALL THE WIRELESS SIGNAL. CONNECT A SMALL PIECE FOIL TO THE WIRELESS MODEM ANTENNA MIGHT INCREASE THE RANGE A BIT SOME TIME BUT USUALLY NOT WORKING WELL.

- Q: What are the different hardness levels of aluminum coils?

- There are various hardness levels of aluminum coils, which are classified based on the alloy and tempering process used during their manufacturing. The most common hardness levels for aluminum coils are: 1. Soft (O temper): This is the most malleable and ductile state of aluminum coils. They are highly formable and suitable for applications that require extensive shaping or bending. 2. Quarter Hard (H12 temper): Aluminum coils in this hardness level have undergone a slight cold-working process, which increases their strength and stiffness. They are less malleable than soft coils but still retain good formability. 3. Half Hard (H14 temper): Coils in this hardness level have undergone a moderate cold-working process, resulting in further increased strength and stiffness. They are less formable than quarter-hard coils but are ideal for applications that require higher strength. 4. Three Quarter Hard (H16 temper): Aluminum coils in this hardness level have undergone a more intensive cold-working process, making them even stronger and less formable than half-hard coils. They are suitable for applications that require high strength and minimal deformation. 5. Full Hard (H18 temper): Coils in this hardness level have undergone the most extensive cold-working process, resulting in maximum strength and minimal formability. They are commonly used in applications that require high structural integrity and resistance to deformation. It is important to note that the specific hardness levels available for aluminum coils may vary depending on the alloy and manufacturer. Additionally, different industries and applications may have specific requirements for hardness levels, so it is crucial to choose the appropriate hardness level based on the intended use of the aluminum coils.

- Q: Explain the distinctions among various types of aluminum coils, including their properties and applications.

- <p>Aluminum coils are differentiated based on their alloy composition, thickness, temper, and surface finish. Common types include 1000 series coils, which are pure aluminum with high ductility but low strength; 3000 series, known for their formability and used in cookware; 5000 series, which are non-heat-treatable and corrosion-resistant; and 6000 series, offering a balance of strength and corrosion resistance. Thickness varies from thin gauges for flexible applications to thick gauges for structural use. Tempers range from soft (O temper) to fully hard (H temper), affecting the coil's hardness and strength. Surface finishes can be plain, coated, or embossed, impacting aesthetics and performance. Each type is chosen based on specific industry requirements like construction, automotive, or packaging.</p>

- Q: This is not for around the house. It is for my lab. I am pretty sure these one wires are Aluminum, but I need the connector they were made with and the power cable is copper. Would it be okay to still try to join the two.

- They can be joined but only through a suitable device marked specifically for aluminum to copper connections. See website below.

Send your message to us

Aluminum Coil Rolling Thailand - Aluminium Coating Coil with Wood Grain

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords