Aluminum Grade A1xxx Cold Rolled CC Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

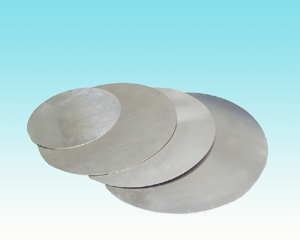

1.Structure of Aluminum Cirlces C.C Quality 1xxx Description:

Aluminum circles C.C quality 1xxx is made from aluminum coils 1xxx. Aluminum circles C.C quality 1xxx has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum circles C.C quality 1xxx are widely used for kitchen wares including fried pans, non-sticky pans, cooking pots,hard anodized cookware, pressure cooker and house hold utensils.

2. Aluminum Cirlces D.C Quality 1xxx Quality Specification:

A1XXX Hot Rolled DC Aluminium Circle

1) alloy number 1050 1060 1070 1100 1200 3003.

2) temper available O H12 H14 H16 H18.

3) application: cookware utensil and basin.

4) thickness: 0.5-4.0mm.(+/-0.02mm)

5) diameter: 100-1200mm.(+/-0.5mm)

6) production treatment: cold rolled

7) surface appearance: flat clean surface no scratch, oil dirty and oxidation.

8) cutting edge: neat cutting edge no burrs.

3.Aluminum Circles D.C Quality 3XXX Images

4. FAQ of D.C Quality 1xxx Specification:

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the quality.

B.When will you deliver the products?

The goods will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What safety measures should be taken into account while handling or working with aluminum?

- <p>When working with aluminum, it's crucial to follow safety precautions to prevent injuries and health risks. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against aluminum dust. Ensure good ventilation to avoid inhaling aluminum dust or fumes. Use proper tools and equipment to handle aluminum, as it can become sharp and cause cuts. Be cautious when welding or cutting aluminum, as it can produce harmful fumes and sparks. Store aluminum in a dry place to prevent it from reacting with moisture. Lastly, be aware of the fire hazard associated with aluminum dust and take necessary fire safety measures.</p>

- Q: This question asks for an overview of the methods used to produce aluminum items.

- <p>Aluminum products are manufactured through several key processes. First, aluminum ore, typically bauxite, is mined and then processed to extract alumina (aluminum oxide). This is done through the Bayer Process, where bauxite is dissolved in caustic soda and heated, followed by precipitation of alumina. The next step is smelting, where alumina is reduced to aluminum metal using the Hall-H茅roult process, involving the electrolysis of molten alumina in a cryolite bath. Once aluminum is obtained, it can be cast into various shapes or forms. Further manufacturing processes include extrusion, forging, rolling, and machining to create specific aluminum products such as sheets, rods, or complex components. These processes can be followed by surface treatments like anodizing, painting, or coating to enhance the product's properties or appearance.</p>

- Q: Explain how the inclusion of copper in aluminum alloys influences their strength and ductility.

- <p>Adding copper to aluminum alloys significantly increases their strength, particularly in the form of tensile and yield strength. Copper acts as a hardening agent, creating a more rigid structure within the alloy. However, this increase in strength often comes at the expense of ductility. As copper content rises, the ductility of the aluminum alloy decreases because copper reduces the alloy's ability to deform under stress without fracturing. The balance between strength and ductility is crucial in alloy design, as higher strength alloys may be less suitable for applications requiring formability and flexibility.</p>

- Q: This question asks about the impact of aluminum on human health, including potential effects and health concerns.

- <p>Aluminum is a common element that can be found in various forms in the environment. While it is not considered an essential nutrient for the human body, it can be ingested through food, water, and medications. In small amounts, aluminum is generally considered safe and is excreted by the body. However, excessive exposure or intake can lead to potential health concerns. Aluminum has been linked to neurological disorders, particularly Alzheimer's disease, although the exact relationship is still a subject of debate. It can also cause bone disorders and affect kidney function. The human body has mechanisms to regulate aluminum levels, but individuals with impaired kidney function may be at a higher risk of aluminum toxicity.</p>

- Q: Is it possible to use aluminum as a fuel source?

- <p>Aluminum can be used as a fuel in certain applications, particularly in the form of aluminum powder. It has a high energy density and burns at high temperatures, making it suitable for solid rocket propellants and thermite reactions. However, it is not commonly used as a traditional fuel like gasoline or coal due to its reactivity and the challenges in handling and storage. Aluminum combustion also produces aluminum oxide, which can be harmful to the environment if not managed properly.</p>

- Q: This question asks for an overview of the environmental effects resulting from the production of aluminum.

- <p>Aluminum production has several significant environmental impacts. The process is energy-intensive, contributing to high greenhouse gas emissions, primarily CO2, which exacerbates climate change. It also generates hazardous waste, such as red mud, a byproduct rich in alkaline and heavy metals that can contaminate soil and water if not properly managed. Air pollution is another concern, with emissions of particulates and sulfur dioxide affecting air quality. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction, impacting biodiversity. Water usage in the production process is substantial, which can strain local water resources. Lastly, the release of fluoride compounds can have detrimental effects on human health and the environment.</p>

- Q: This question asks about the methods and steps involved in processing aluminum.

- <p>Aluminum processing involves several key steps: extraction from bauxite ore, refining, and fabrication. Initially, bauxite is mined and then processed to remove impurities. The Bayer process is commonly used to extract alumina (aluminum oxide) from bauxite by dissolving it in a caustic soda solution. The alumina is then smelted in a reduction furnace using the Hall-H茅roult process, where it is dissolved in molten cryolite and electrolyzed to produce pure aluminum. Finally, the aluminum is shaped and fabricated into various products through methods such as casting, extrusion, or rolling.</p>

- Q: This question asks for typical applications of aluminum foil in everyday life.

- <p>Aluminum foil is commonly used for food storage, as it helps preserve freshness and prevents freezer burn. It's also used in cooking, either to cover dishes to retain moisture or to create packets for steaming or baking. In the kitchen, it's often used to line baking sheets to prevent food from sticking. Beyond cooking, aluminum foil is used for insulation, in arts and crafts, and even for cleaning purposes, such as buffing glass or polishing silverware. It's a versatile material found in many households and commercial settings.</p>

- Q: Explain the economic and job market implications of using aluminum.

- <p>The use of aluminum has significant impacts on the economy and job market. It is a key material in various industries, including construction, automotive, aerospace, and consumer goods, which drives demand and economic growth. Aluminum production and processing create jobs directly in mining, refining, and manufacturing sectors, and indirectly in related services and supply chains. Additionally, its lightweight and corrosion-resistant properties make it valuable for energy-efficient transportation, contributing to environmental sustainability and opening new job opportunities in green technologies. However, it also presents challenges such as the need for energy-intensive production processes and the management of waste, which require innovative solutions and can lead to job creation in recycling and environmental management.</p>

- Q: Explain the different methods used for recycling aluminum.

- <p>Aluminum recycling methods primarily include mechanical recycling and re-melting. Mechanical recycling involves cleaning, shredding, and sorting aluminum waste before reprocessing it into new products. Re-melting involves melting aluminum scrap and then casting it into new aluminum products. This process is energy-efficient, as it requires only 5% of the energy needed to produce aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it one of the most recyclable materials.</p>

Send your message to us

Aluminum Grade A1xxx Cold Rolled CC Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches