China Pvdf Coated Aluminum Coil - Aluminium CC DC Cold Rolling Coil and Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description

Aluminium is a relatively soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa.

2. Specification

ALUMINIUM COIL

ALLOY: AA1***

AA3***

AA5***

TEMPER: H14 H16 H18 H22 H24 H26 H32 O/F

THICKNESS:0.03MM-3.0MM

WIDTH: 30MM-1700MM

COATING: PE(POLYESTER),PVDF,EPOXY

STANDARD: GB/T 17748-1999

3. Advantage

Best Price!

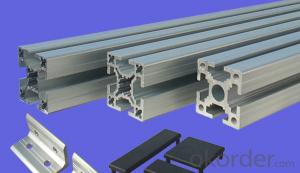

4. Pictures

5. FAQ

1)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2)How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How do aluminum coils contribute to sustainable energy systems?

- There are several reasons why aluminum coils are crucial in sustainable energy systems. Firstly, aluminum is a lightweight metal that conducts electricity well, making it ideal for producing coils used in renewable energy technologies like wind turbines, solar panels, and electric vehicles. By using aluminum coils, these systems become more efficient and perform better due to the reduced weight. Secondly, aluminum is abundant in nature and can be recycled multiple times without losing its original properties. This results in significant energy savings and less environmental impact. By using aluminum coils, sustainable energy systems can reduce their reliance on new materials and support a circular economy. Furthermore, aluminum coils are resistant to corrosion and have excellent heat transfer properties. This makes them highly durable and capable of withstanding harsh weather conditions, ensuring the longevity and reliability of renewable energy systems. The durability of aluminum coils also reduces the need for frequent maintenance or replacements, minimizing waste generation and conserving resources. Moreover, aluminum is a non-toxic material that poses minimal risks to human health and the environment. Unlike other metals, aluminum does not release harmful substances into the soil or water. This makes it a safe choice for sustainable energy systems. Lastly, the use of aluminum coils in sustainable energy systems helps to reduce greenhouse gas emissions. Due to its lightweight nature, aluminum requires less energy for transportation and installation, thereby reducing the carbon footprint associated with manufacturing and installation processes. Additionally, the increased efficiency and performance of renewable energy systems using aluminum coils contribute to the displacement of fossil fuel-based energy generation, leading to a decrease in overall carbon emissions. In conclusion, aluminum coils play a significant role in sustainable energy systems by improving the efficiency, durability, recyclability, and environmental friendliness of renewable energy technologies. Their lightweight nature, resistance to corrosion, and excellent heat transfer properties make them suitable for various applications. Additionally, their abundance and recyclability support resource conservation and a circular economy. By using aluminum coils, sustainable energy systems can reduce their environmental impact, enhance performance, and contribute to a cleaner and more sustainable future.

- Q: Can aluminum coils be recycled?

- Yes, aluminum coils can be recycled. Aluminum is one of the most commonly recycled materials due to its high recyclability. The recycling process for aluminum coils involves melting them down to remove any impurities and then reshaping them into new products or coils. Recycling aluminum coils not only helps conserve natural resources but also reduces energy consumption and greenhouse gas emissions compared to producing new aluminum from raw materials.

- Q: I would like to know why the ionic substance aluminium oxide doesn't dissolve in water.

- It does dissolve, but only slightly. It has a solubility of about 0.0001 under atmospheric pressure, it doesn't dissolve because the aluminium is extremely strongly bonded to oxygen, so it can't dissociate very much at all. If you want to dissolve aluminium oxide, you should use an alkaline solution.

- Q: Are there any specific regulations for the transportation of aluminum coils?

- Yes, there are specific regulations for the transportation of aluminum coils. These regulations aim to ensure the safe handling and transport of aluminum coils to prevent any accidents or damage. Some of the key regulations include: 1. Packaging requirements: Aluminum coils should be properly secured and packaged in suitable containers to prevent shifting, damage, or falling during transportation. This may include the use of strapping, banding, or shrink-wrapping. 2. Weight restrictions: There are weight restrictions on the transport of aluminum coils, which vary depending on the type of transportation mode being used. These restrictions are in place to ensure the stability and safety of the vehicle during transit. 3. Loading and unloading procedures: Proper loading and unloading procedures should be followed to minimize the risk of damage to the coils and to ensure the safety of workers. This may involve the use of specialized equipment such as cranes or forklifts. 4. Hazardous materials regulations: In some cases, aluminum coils may be considered hazardous materials due to their flammability or other characteristics. If this is the case, additional regulations and requirements may apply, such as proper labeling, documentation, and handling procedures. 5. Transportation permits: Depending on the size, weight, and destination of the aluminum coils, specific permits or licenses may be required for their transportation. These permits ensure compliance with local, state, and federal regulations. It is important for companies involved in the transportation of aluminum coils to be aware of and comply with these regulations to ensure the safe and efficient transport of the coils. Failure to adhere to these regulations can result in fines, penalties, or even legal consequences.

- Q: I had a physics exams today and it was asking whether or not a shiny surface aluminium blanket was suitable to keep the sleeper warm. I put that because it's a conductor of electricitiy, heat loss will be greater so it wont be suitable for keeping him warm. On the other hand, some other people said that because it had a shiny surface, thus a good reflector of heat, it would be suitable for keeping him warm. Are both arguments correct?

- Electrical conductivity has nothing to do with it. Emergency blankets of the type you describe have much lower thermal conductivity than metallic aluminium. The shiny surfaces both reflect body heat back to the body and do not radiate heat away. The sun is not involved in its operation as they work equally well at night or in other unlit places.

- Q: What style of womens Oakley sunglasses come in aluminum? I need a tough pair and would like interchangeable lenses option also.

- You can go to this website to buy it.My friends have bought the oakley sunglasses from this site,so you can rest assured,it is the real website.The products are nice replicas,they are of high quality and also lower price.I believe you can buy the one you want from this site.

- Q: How much is one square aluminum gate and five hard door?

- On the Alibaba website search "roll gate", there are many manufacturers, you can ask them.

- Q: This question asks for a comparison of the costs involved in purchasing new aluminum coils versus recycling old ones.

- <p>The cost of buying new aluminum coil versus recycling old ones can vary significantly based on several factors including market prices, quality of the recycled material, and the cost of recycling processes. Generally, recycling aluminum is more cost-effective as it requires less energy and resources compared to producing new aluminum from raw materials. The cost of recycled aluminum can be as low as half of that for new aluminum. However, the exact cost will depend on current market conditions and the specific requirements of the aluminum coils in question. It's advisable to get quotes from suppliers and recycling companies to determine the most economical option for your specific needs.</p>

- Q: Can aluminum coils be used in the production of fire-resistant structures?

- Yes, aluminum coils can be used in the production of fire-resistant structures. Aluminum has a high melting point and excellent thermal conductivity, making it suitable for applications where fire resistance is required. Additionally, aluminum does not burn and can help to prevent the spread of fire, making it a popular choice for fire-resistant structures such as fire doors, fire-resistant walls, and fireproof insulation.

- Q: How are aluminum coils used in the production of marine vessels?

- Aluminum coils are extensively used in the production of marine vessels due to their unique properties and advantages. Firstly, aluminum is a lightweight material compared to other metals commonly used in shipbuilding such as steel. This characteristic makes it ideal for constructing marine vessels as it reduces the overall weight of the ship, allowing it to float more easily in water. The use of aluminum coils in the construction process ensures that the vessel remains buoyant without compromising its structural integrity. Secondly, aluminum is highly corrosion-resistant, especially when exposed to saltwater environments. Marine vessels are constantly exposed to water, which can be corrosive and damaging to metal components. By using aluminum coils, shipbuilders can minimize the risk of corrosion and increase the longevity of the vessel. Moreover, aluminum coils offer excellent thermal conductivity. This property is crucial in marine vessels as it helps dissipate heat generated by engines, machinery, and equipment, ensuring that the ship operates efficiently and safely. Additionally, aluminum coils can be easily formed, shaped, and welded, making them highly malleable and adaptable for various shipbuilding requirements. This flexibility allows shipbuilders to create complex and streamlined designs, optimizing the vessel's performance and fuel efficiency. Furthermore, aluminum coils are environmentally friendly as they are 100% recyclable, reducing the carbon footprint associated with marine vessel production. This aspect aligns with the growing demand for sustainable and eco-friendly shipbuilding practices. In conclusion, aluminum coils play a vital role in the production of marine vessels. Their lightweight nature, corrosion resistance, thermal conductivity, malleability, and recyclability make them an ideal choice for shipbuilders. By utilizing aluminum coils, marine vessels can be constructed to be more efficient, durable, and environmentally friendly.

Send your message to us

China Pvdf Coated Aluminum Coil - Aluminium CC DC Cold Rolling Coil and Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords