Ceramic Filter Plate Alumina Grinding Ball with Higher Hardness and Density

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

APPLICATION

Being the high quality grinding media, Alumina Grinding Ball is superior in higher hardness and density, better toughness and erosion resistance, as well as regular shape. It is widely applied in ceramic, cement, paint, pigment, chemical, pharmacy, coating and mining industries.

Typical Characteristics JIN GANG Alumina Grinding Ball

Item JG92-1 JG92-2 JG75 JG68

Al2O3+ZrO2(%) 92 92 73~78 68

Bulk Density(g/cm3) 3.65 3.6 3.25 2.9

Water Absorption(%) <0.1 <0.1 <0.1 <0.1

Wear Loss(‰) ≤0.1 ≤0.15 ≤0.2 ≤0.4

Hardness(Mohs) 9 9 8 7~8

Color White White White Yellow White

Application Glaze Milling,Tile body Milling Glaze Milling,Tile body Milling Glaze Milling,Tile body Milling Glaze or Tile body Milling

Raw Materials Calcined Alumina Calcined Alumina Zirconia,Calcined Alumina Refined Bauxite Powder

Forming Method CIP CIP CIP CIP

Diameter(mm) 0.2~70;Can be customized accordingly.

Note:

(1)Wear loss is tested according to the Chinese National Standard JC/T848.1-2000.

(2)Above technical data is typical test result,the real value may change within acceptable tolerance.

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- If it is found that the ceramic plate is broken, it should stop in time to replace the broken ceramic plate. Ceramic filter is produced by vacuum suction vacuum pump to the pulp in the water through the ceramic plate away, the surface aperture ceramic plate for several microns, so it can intercept the cake on the ceramic plate on the surface, if the ceramic plate is broken, a hole is a few millimeters, when the vacuum suction pump when they go together along with the pulp pump.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: Why does not the iron filter of the ceramic filter work?

- You should make it clear that the filter cake has always been dry or suddenly dry, and now how much moisture? Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- In unit time, the more turns of the drum, the greater the centrifugal force, the greater the rate of filtration in unit time, that is to say, the amount of filtrate in unit time is moreRotating drum vacuum filter, the greater the speed, the greater the filtration rate, but the shorter the time each turn, the amount of each filtrate will be reduced

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- The vacuum degree of the ceramic filter is normal at about -0.08MPa. Under normal circumstances, the water content of the filter cake treated with a ceramic filter is about 10%, and the moisture content of the tail filter cake is about 15%. The water content of the filter cake increases with the increase of water content in the ceramic filter. I analyze the reasons from two aspects.

- Q: Ceramic filter capacity.

- You ask too general, to say processing capacity (ie capacity), at least to provide material conditions, such as: material name, concentration, particle size distribution. In addition, the basic conditions of equipment operation should be taken into account.

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Can be washed with chromic acid lotion. The effect is better

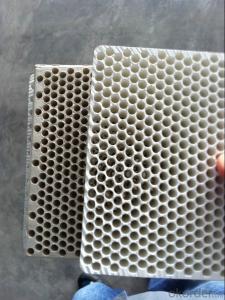

- Q: What are the functions of honeycomb ceramic filters?

- High quality and high density straight hole mesh, the product has high heat resistance and impact resistance properties of cast high fever temperature, design straight hole to guarantee the balance between strength and flow, effectively remove impurities and slag particles, the mechanical properties of casting, the surface quality and the qualified rate of products is greatly improved.

- Q: Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- Beneficiation of ceramic filter, the technical parameters are normal, but the water will fill in groove is what reason

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- The filtrate pump works to drain or recycle the water that has been pumped out. 6 、 cleaning system work, cleaning system includes backwashing (water pump pressure or height difference pressure), acid liquid (metering pump, automatic acid injection), ultrasonic (ultrasonic work), etc.. 7 、 control system and other electrical systems. In addition, the filter cake which is absorbed and dried on the ceramic filter plate is unloaded automatically by the scraper and then falls on the belt conveyor, and is conveyed to the concentrate storage yard by a belt conveyor. Other questions about ceramic filter, welcome to chat with me or look at my head

Send your message to us

Ceramic Filter Plate Alumina Grinding Ball with Higher Hardness and Density

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords