Ceramic Filter Plate - Casting Used Porous Alumina Ceramic Foam Filter for Foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description of ceramic foam filter

Ceramic foam filter is a kind of effective molten metal filter. It’s three-dimensional connected mesh skeleton structure and high porosity makes it has many advantages,large surface area of slags collection,large inner surface area of filtering,Small flow resistance,good filtering effect,etc.

2. Functions of ceramic foam filter

decontaminate the melting metal liquid,Simplified gating system

Improve the metallurgical structure of the castings,Reduce imparities of the castings

Improve casting quality rate,Reduce casting internal re-oxidation defects

Reduce the surface defects after machining of the castings

3.Physical and chemical properties

Material | Alumina | Silicon Carbide | Zirconia | Magnesia |

Color | White | Grey black | Yellow | Dark yellow |

Pore Density | 8-60ppi | 8-60ppi | 8-60ppi | 8-60ppi |

Porosity | 80-90% | 80-90% | 80-90% | 80-90% |

Refractoriness | ≤1100°C | ≤1500°C | ≤1700°C | ≤1000°C |

Bending Strength | >0.6Mpa | >0.8Mpa | >1.0Mpa | >0.6Mpa |

Compression Strength | >0.8Mpa | >0.9Mpa | >1.2Mpa | >0.8Mpa |

Volume-weight | 0.3-0.45g/cm3 | 0.35-0.5 g/cm3 | 0.9-1.5 g/cm3 | 0.35-0.5 g/cm3 |

Thermal shock resistance | 6times/1100°C | 6times/1100°C | 6times/1100°C | 6times/1100°C |

Application | Aluminium , Aluminium alloys and other Non-ferrous alloys | Ductile Cast Iron, Malleable Cast Iron,Gray iron and other Cast Iron | High melting point metal alloys likeSteel,AlloySteel,Stainless Steel etc | Magnesium and High-Active Alloy |

Specifications for Alumina Casting

Dimensions (mm) | Dimensions (inch) | Pouring Rate (kg/s) | Filtration Capacity (ton) |

178×178×50 | 7×7×2 | 0.2-0.6 | 5 |

228×228×50 | 9×9×2 | 0.3-1.0 | 10 |

305×305×50 | 12×12×2 | 0.8-2.5 | 15 |

381×381×50 | 15×15×2 | 2.2-4.5 | 25 |

430×430×50 | 17×17×2 | 3.0-5.5 | 35 |

508×508×50 | 20×20×2 | 4.0-6.5 | 45 |

585×585×50 | 23×23×2 | 5.0-8.6 | 60 |

Specification for Iron casting

Dimension (mm) | Pouring Rate (kg/s) | Filtration Capacity (kg) | ||

Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | |

40×40×22 | 4 | 3 | 65 | 32 |

50×50×22 | 6 | 4 | 100 | 52 |

75×50×22 | 9 | 6 | 150 | 75 |

75×75×22 | 14 | 9 | 220 | 100 |

100×50×22 | 12 | 8 | 200 | 100 |

100×75×22 | 18 | 12 | 300 | 150 |

100×100×22 | 25 | 16 | 400 | 200 |

150×150×22 | 50 | 36 | 900 | 450 |

Specification for Steel/Magnesium casting

Dimensi | Zirconia Foam Filter | Dimensions (mm) | Magnesia Foam Filter | ||

Pouring Rate(kg) | Filtration Capacity(kg) | Pouring Rate(kg) | Filtration Capacity(kg) | ||

50×50×22 | 3~5 | 30 | 50 D×22 | 4.0 | 60 |

50×75×22 | 4~6 | 40 | 60 D×22 | 7.0 | 80 |

75×75×22 | 7~12 | 60 | 90 D×22 | 10.0 | 120 |

75×100×22 | 8~15 | 80 | 120 D×22 | 16.0 | 160 |

100×100×22 | 14~20 | 100 | 100×100×22 | 13.0 | 140 |

50 D×22 | 2~6 | 18 | 150×150×25 | 22.0 | 260 |

80 D×22 | 6~10 | 50 | 230×230×30 | 130.0 | 3100 |

90 D×22 | 8~16 | 70 | 300×300×40 | 260.0 | 5200 |

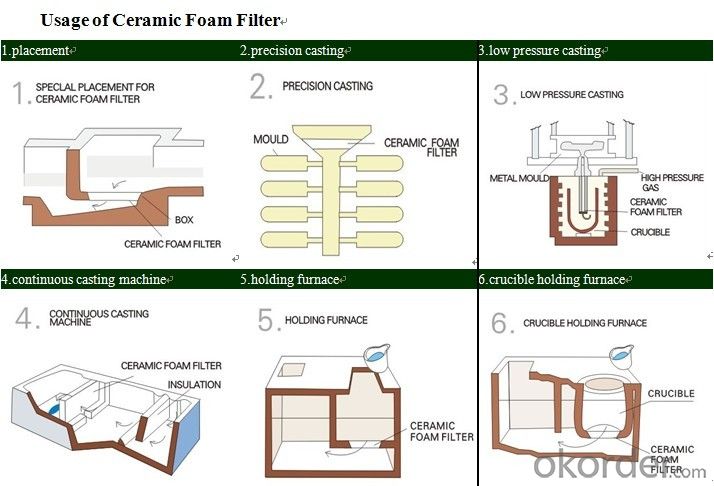

4.Usage of ceramic foam filter

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: Why does not the iron filter of the ceramic filter work?

- You should make it clear that the filter cake has always been dry or suddenly dry, and now how much moisture? Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- As everyone knows, ceramic filter medium is a ceramic filter plate, microporous ceramic filter plate with a lot of distribution from the outside to the inside capillary effect, its mechanism is based on the capillary effect of microporous ceramic filter, filtration, the filtrate (generally refers to water) through these pores under the action of the vacuum suction pump, filter cake is trapped on the surface of the ceramic filter plate.

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q: Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

- Q: The vacuum of ceramic filter is not enough

- Maybe the vacuum meter is broken. It doesn't show or show the data is different from the actual data.It could be the source of the vacuum, the vacuum pump failure.Pipeline leakage: vacuum system connecting pipes (metal pipes or rubber pipes) corrosion, aging and water leakage.Distributor head leakage: wear or poor sealing.Leakage of ceramic plate: rupture of ceramic plate.Other reasons.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: What is the reason that the whole ceramic filter does not attract ore?

- Vacuum system failure, no vacuum or vacuum can not meet the requirements. Should check the vacuum pump and vacuum piping, distribution head, ceramic plate, such as failure or leakage.Whether the ore conditions are changed, such as pulp type, mud content, fineness, concentration, etc..

- Q: Can the ceramic plate filter the hot air?

- The vacuum degree of the ceramic filter in the vacuum system is about -0.085MPa. If the abnormal vacuum is found, the normal vacuum suction will not be available, and the suction effect will be poor, even without suction. If the vacuum is abnormal, should adhere to the vacuum pump, vacuum connection pipe is whether the fault Water Leakage leakage, distribution valve friction sealing, ceramic filter plate is connected with the rubber tube is aging or exfoliation, ceramic filter plate rupture.

Send your message to us

Ceramic Filter Plate - Casting Used Porous Alumina Ceramic Foam Filter for Foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords