Al-Zinc coated steel Coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

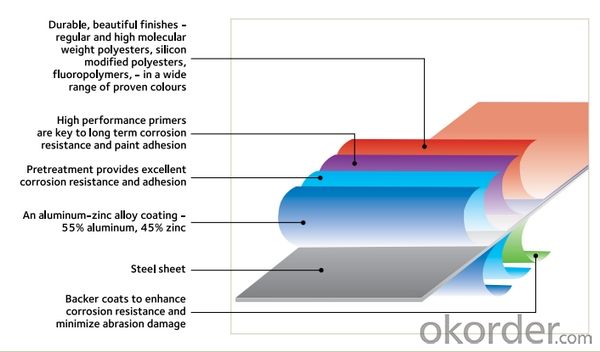

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: what happened to all the steel beams from the WTC buildings? did anyone do any forensic analysisof any of the steel?

- some of the steel was recycled into a warship. I am not sure at what you are trying to get at with the forensic analysis of the steel. There is no conspiracy involving the towers outside of planes crashing into them despite what a lunatic fringe want you to think.

- Q: How are steel coils processed for painting or coating?

- Steel coils are typically processed for painting or coating through a series of steps. First, the coils are cleaned to remove any dirt, oil, or rust. This is usually done through a chemical cleaning process or by using mechanical methods such as shot blasting. Next, the coils are pre-treated to enhance adhesion and corrosion resistance. This can involve applying a conversion coating or a primer. Finally, the coils are painted or coated using a variety of methods such as roll coating, spray coating, or electrostatic coating. The specific process depends on the desired finish and application requirements.

- Q: What are the different coil slitting line configurations used for steel coils?

- There are several different coil slitting line configurations used for steel coils, including the looping pit slitting line, the looping tower slitting line, the non-looping slitting line, and the traveling head slitting line. Each configuration offers unique advantages and is suited for specific applications and production requirements.

- Q: How are steel coils cut and shaped for specific requirements?

- Steel coils are cut and shaped for specific requirements through a process called slitting and forming. Slitting involves unwinding the coil and passing it through a set of circular blades that cut it into narrower strips. These strips can then be further processed through different forming techniques such as roll forming, stamping, or bending to achieve the desired shape and dimensions. This allows manufacturers to customize steel coils according to specific requirements for various applications in industries like automotive, construction, and manufacturing.

- Q: How are steel coils processed for different levels of hardness?

- Different levels of hardness can be attained in steel coils using a variety of methods. One common approach is heat treatment, in which the coils are heated to a specific temperature and then rapidly cooled to modify their microstructure and achieve the desired hardness. The heat treatment process can encompass quenching, tempering, or annealing, depending on the desired hardness level. Quenching involves quick cooling of the coils in a liquid medium like water or oil to achieve a high hardness level. On the other hand, tempering requires reheating the coils to a lower temperature and gradually cooling them to attain a desired balance between hardness and toughness. Annealing, on the other hand, involves heating the coils to a specific temperature followed by slow cooling to release internal stresses and obtain a softer and more malleable material. Additionally, mechanical processes like cold rolling or cold working can be employed to enhance the hardness of steel coils. These processes involve applying compressive forces to the coils, causing the material to deform and resulting in increased hardness. Overall, achieving different hardness levels in steel coils requires meticulous control of temperature, cooling rate, and mechanical forces to obtain the desired properties for specific applications.

- Q: What's the length of a coil of cold rolled steel? Is there a standard?

- In 2.0*1000*C calculations, it is assumed that the formula for the length of 5T in this volume is 5000/ (2.0*1000*1000*7.93) = the total number of meters. First, the weight of one meter is calculated by dividing the total weight by the single weight, that is, the theoretical length of the volume

- Q: How do steel coils perform in corrosive environments?

- Steel coils typically perform well in corrosive environments due to their inherent resistance to corrosion. This is primarily because steel is an alloy composed of iron and other elements, such as carbon, which provides it with a protective layer known as a passive film. This passive film acts as a barrier between the steel surface and the corrosive elements, preventing direct contact and thus minimizing the risk of corrosion. In addition to the passive film, steel coils can also be coated with various protective coatings to enhance their resistance against corrosion. These coatings, such as zinc or epoxy, provide an additional layer of protection and further extend the lifespan of the steel coils when exposed to corrosive environments. However, it is important to note that the performance of steel coils in corrosive environments can still be influenced by factors such as the specific corrosive agent, exposure duration, and the presence of other contaminants. In highly aggressive environments, such as those with high humidity, saltwater exposure, or acidic chemicals, the protective layers on steel coils may deteriorate over time, leading to potential corrosion. To ensure optimal performance in corrosive environments, it is advisable to select steel coils with corrosion-resistant properties, such as stainless steel or galvanized steel. Regular maintenance and inspections are also crucial to identify any signs of corrosion early on and take appropriate measures to prevent further damage. Overall, steel coils offer good resistance to corrosion in most environments, but the severity of the corrosive conditions can ultimately impact their performance.

- Q: I just bought a dpms ar15 and it says if I shoot steel cases (laquer coated) or foreign ammo it voids the warranty. But before I knew this I bought 200 rounds of Russian steel cased anmo. Think I should just shoot there two hundred and not buy anymore? Some people say all they shoot is steel cased ammo and have no problemAny advice is appreciated

- Steel Case Ammo

- Q: I like non-stick cookware but it dont hold up no matter how much money you spend. What isthe best kind? Is there something better then stainless steel or iron skillet? I do not care if I have to use extra elbow grease to clean a pan.

- I have a combination of them both. I have Le Creuset enameled cast iron dutch-ovens, pots and pans; as well as All Clad stainless steel saute and deep-rimmed pans which have a copper core. I have one non-stick pan that I use for cooking eggs in.

- Q: I downloaded broken steel, the notice of my level cap raising was shown, but after reaching the Jefferson Memorial (when you are supposed to activate the purifier) if I kill Colonel Autumn, then Lyons simply says that we must secure the area, and I can't complete the mission. If I let Autumn live, then she gets stuck in a loop saying Steel be with you over and over. Has anyone else experienced this/how can I fix this? I paid $10 for the expansion and I'm getting ripped off.

- Broken Steel alters the ending of the original Fallout 3 to allow continued play after the end of the main quest line. This means that when it is time to go into the reactor at the end of Take it Back!, you can still go in yourself or you can send one of three side characters. However, even if you go yourself, you do not die. Instead, you survive the ordeal and wake up two weeks later at the Citadel. If you allow the Purifier to explode, the game will still end. Elder Lyons will inform you that you and Sarah Lyons were knocked unconscious by an unknown energy spike. Sarah will still be in a coma

Send your message to us

Al-Zinc coated steel Coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords