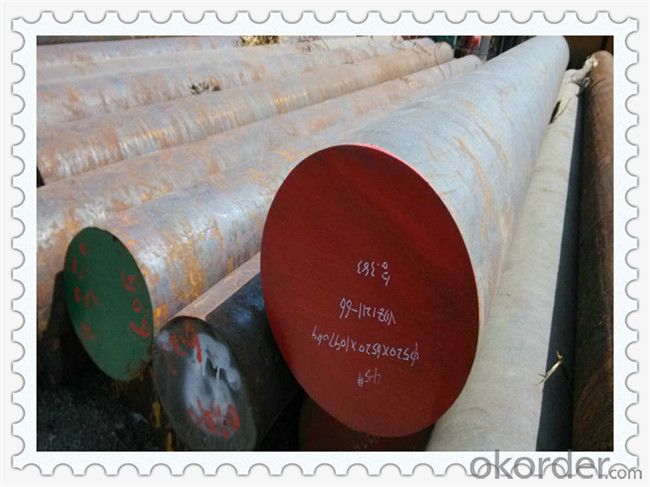

AISI A2 Mould Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

AISI A2 Mould Steel Round Bar

![]()

GB | DIN | AISI | JIS |

Cr5Mo1V | 1.2363 | A2 | SKD12 |

![]()

C | Si | Mn | Cr | P | S | V | Mo |

0.90-1.05 | 0.20-0.40 | 0.40-0.80 | 4.80-5.50 | 0.03MAX | 0.03MAX | 0.10- 0.30 | 0.90-1.20 |

![]()

Round Steel Bar | 60-800mm |

Flat Steel Bar | 25-400mm*200-800mm |

![]()

Black surface/ Grinded/ Machined

Annealed HB241 max

AISI A2 Die Steel Round Bar / Die Steel Bar A2 is of Good machine ability, good

dimension stability, excellent compressive strength, good toughness, high wear

resistance, high through harden ability.

![]()

AISI A2 Die Steel Round Bar / Die Steel Bar A2 is for making Cutting operations,

embossing dies, cutting, punching, stamping, bending tools, shear blades, moulds for

plastic processing.

- Q: Can steel round bars be heat treated to improve their mechanical properties?

- Steel round bars can undergo heat treatment to enhance their mechanical properties. Heat treatment involves heating the steel to a specific temperature, maintaining it at that temperature for a certain duration, and then cooling it rapidly or slowly. This process can modify the microstructure of the steel, resulting in changes to its hardness, strength, toughness, and other mechanical properties. Various types of heat treatment processes can be applied to steel round bars, depending on the desired outcome. For instance, annealing is a process that entails heating the steel to a specific temperature and subsequently cooling it gradually. This method helps alleviate internal stresses in the steel, enhance its ductility, and facilitate machining. Another commonly used heat treatment process is quenching and tempering. This involves heating the steel to a specific temperature and rapidly cooling it, often by immersing it in an oil or water quenching medium. This swift cooling process helps strengthen the steel, making it more resistant to wear and abrasion. Following quenching, the steel is typically tempered by reheating it to a lower temperature, reducing its brittleness and improving its toughness. In addition to annealing and quenching and tempering, other heat treatment processes such as normalizing, case hardening, and precipitation hardening can also be employed to enhance the mechanical properties of steel round bars. These processes involve different heating and cooling techniques, and are utilized to achieve specific outcomes based on the desired properties of the steel. Overall, heat treatment is a versatile and effective approach for improving the mechanical properties of steel round bars. By carefully controlling the heating and cooling process, significant improvements in hardness, strength, toughness, and other properties can be achieved, rendering the steel suitable for a wide range of applications.

- Q: What are the advantages of using free-cutting steel round bars?

- There are several advantages of using free-cutting steel round bars. Firstly, free-cutting steel round bars are known for their excellent machinability. They are specifically designed to be easily machined, allowing for smooth and efficient cutting, drilling, and shaping processes. This makes them ideal for applications where precision and intricate detailing are required, such as in the manufacturing of automotive components, machinery parts, and precision instruments. Secondly, free-cutting steel round bars offer improved productivity and reduced manufacturing costs. The enhanced machinability of these bars significantly reduces the time and effort required to machine them, resulting in higher production rates and increased efficiency. Additionally, the reduced wear and tear on cutting tools leads to longer tool life, reducing tool replacement costs and overall manufacturing expenses. Furthermore, free-cutting steel round bars exhibit excellent chip control. During machining, the chips produced can affect the surface finish and dimensional accuracy of the final product. Free-cutting steel round bars are specifically formulated to produce small, manageable chips that are easily expelled from the cutting zone. This not only improves the quality of the machined parts but also minimizes the risk of chip clogging or chip-related issues. Another advantage of using free-cutting steel round bars is their superior surface finish. These bars are often produced with a fine grain structure and low levels of impurities, resulting in a smooth and visually appealing surface finish. This is especially important for applications where aesthetics and appearance play a significant role, such as in architectural designs or decorative purposes. Lastly, free-cutting steel round bars offer excellent mechanical properties. They are typically manufactured with controlled chemical compositions and heat treatments, ensuring consistent and reliable mechanical performance. This makes them suitable for demanding applications that require high strength, toughness, and durability. In conclusion, the advantages of using free-cutting steel round bars include excellent machinability, improved productivity, reduced manufacturing costs, superior chip control, enhanced surface finish, and reliable mechanical properties. These benefits make free-cutting steel round bars a preferred choice in various industries and applications.

- Q: Can steel round bars be extruded?

- No, steel round bars cannot be extruded. Extrusion is a manufacturing process that involves forcing material through a die to create a specific shape or profile. While steel can be extruded into various shapes, such as tubes, channels, or angles, round bars are typically not produced by extrusion. Instead, steel round bars are usually made through a different process called hot rolling, where a cylindrical billet is heated and passed through a series of rollers to achieve the desired diameter and length.

- Q: What is the machinability of a steel round bar?

- The machinability of a steel round bar refers to how easily it can be shaped, cut, or formed using machining processes such as drilling, milling, or turning. It is influenced by factors such as the composition of the steel, its hardness, and the presence of impurities. Higher machinability indicates that the steel can be machined more efficiently and with less tool wear, while lower machinability may require slower cutting speeds or more frequent tool changes.

- Q: What are the different types of steel round bar surface finishes for corrosion resistance?

- There are several different types of steel round bar surface finishes that are commonly used for corrosion resistance. These finishes provide a protective coating on the surface of the bar, preventing contact with corrosive elements and reducing the risk of rusting or degradation over time. One of the most popular finishes for corrosion resistance is hot-dip galvanizing. This involves immersing the steel round bar in a bath of molten zinc, which forms a layer of zinc coating on the surface. The zinc acts as a sacrificial anode, corroding before the steel does, and providing long-lasting protection against rust and corrosion. Another common surface finish for corrosion resistance is stainless steel. This type of steel contains a minimum of 10.5% chromium, which forms a passive oxide layer on the surface when exposed to oxygen. This layer acts as a barrier, preventing further oxidation and corrosion, making stainless steel round bars highly resistant to rust and other forms of corrosion. Electroplating is another method used to provide corrosion resistance to steel round bars. This process involves immersing the bar in an electrolyte solution and passing an electric current through it. This causes a layer of metal, such as zinc or nickel, to be deposited onto the surface of the bar, providing a protective coating. Powder coating is a popular choice for steel round bars that require both corrosion resistance and aesthetic appeal. This process involves applying a dry powder coating to the surface of the bar and then curing it under heat. The powder melts and forms a hard, durable finish that provides excellent corrosion resistance while also offering a wide range of color options. Additionally, there are specialized coatings available for specific applications, such as epoxy coatings or polymer coatings. These coatings are designed to provide superior resistance to certain corrosive environments, such as exposure to chemicals or high humidity. In summary, the different types of steel round bar surface finishes for corrosion resistance include hot-dip galvanizing, stainless steel, electroplating, powder coating, and specialized coatings. Each of these finishes offers varying levels of protection against rust and corrosion, and the choice of finish depends on factors such as the specific application, environmental conditions, and desired aesthetics.

- Q: What are the different surface treatments for steel round bars?

- There are several different surface treatments available for steel round bars, each serving a specific purpose and providing unique benefits. Some of the most common surface treatments for steel round bars include: 1. Hot-dip galvanizing: This process involves immersing the steel round bars in a bath of molten zinc, which creates a protective coating that helps prevent corrosion and rusting. Hot-dip galvanizing is an effective treatment for steel round bars used in outdoor or corrosive environments. 2. Painting: Applying a coat of paint to the surface of steel round bars not only enhances their appearance but also provides a protective barrier against moisture and oxidation. Painting is commonly used for decorative purposes or when a specific color is desired. 3. Powder coating: Powder coating involves applying a dry powder to the steel round bars, which is then cured under heat to form a durable and attractive finish. This treatment offers excellent resistance to impact, chemicals, and UV rays, making it suitable for various applications. 4. Electropolishing: This process uses an electric current and an electrolyte solution to remove a thin layer of the steel round bars' surface, resulting in a smooth and shiny finish. Electropolishing improves the appearance and corrosion resistance of the steel, making it ideal for applications that require a high level of cleanliness and aesthetics. 5. Passivation: Passivation involves treating the steel round bars with an acid solution to remove any free iron or iron oxide from the surface, thus enhancing their corrosion resistance. Passivation is commonly used for stainless steel round bars to increase their longevity and prevent staining or rusting. 6. Shot blasting: Shot blasting is a mechanical surface treatment that involves bombarding the steel round bars with small steel balls or particles at high velocity. This process removes any surface contaminants, scale, or rust, resulting in a clean and roughened surface that improves adhesion for subsequent coatings or treatments. 7. Chrome plating: Chrome plating is a technique where a thin layer of chromium is electroplated onto the surface of steel round bars. This treatment provides excellent corrosion resistance, wear resistance, and a shiny appearance, making it suitable for applications that require durability and aesthetics. Overall, the choice of surface treatment for steel round bars depends on the specific requirements of the application, such as corrosion resistance, aesthetics, or wear resistance. It is important to carefully consider the intended use and environmental conditions before selecting the most appropriate surface treatment for steel round bars.

- Q: Can steel round bars be used for hydraulic cylinder applications?

- Yes, steel round bars can be used for hydraulic cylinder applications. Steel round bars are commonly used in the manufacturing of hydraulic cylinders due to their high strength, durability, and resistance to corrosion. Additionally, steel round bars can be machined to precise dimensions, allowing for the creation of custom hydraulic cylinder components.

- Q: What are the advantages of using case-hardening steel round bars?

- There are several advantages of using case-hardening steel round bars. Firstly, case-hardening steel offers excellent wear resistance, making it suitable for applications where the material is subjected to abrasion or friction. Secondly, it provides high core strength, ensuring the bar can withstand heavy loads and stresses. Additionally, case-hardening steel round bars have good machinability, allowing for easy shaping and forming. Lastly, the case-hardening process improves the surface hardness of the bar, enhancing its durability and extending its lifespan.

- Q: What is the maximum length of a steel round bar available?

- The maximum length of a steel round bar available depends on various factors such as the manufacturing capabilities of the steel supplier, transportation limitations, and practical considerations. However, typical maximum lengths range from 20 to 40 feet (6 to 12 meters), but it is always best to consult with a steel supplier to determine the specific lengths they offer.

- Q: What are the advantages of using carbon-manganese alloy steel round bars?

- Carbon-manganese alloy steel round bars offer numerous benefits: Firstly, they provide exceptional strength and durability, making them ideal for demanding applications. These bars can withstand heavy loads and resist deformation, ensuring long-lasting performance. Secondly, they possess excellent impact resistance, making them highly suitable for situations where there is a risk of impact or sudden loads. This feature helps to prevent fractures or breakages, enhancing safety and reliability. Furthermore, carbon-manganese alloy steel round bars have good weldability, allowing for easy fabrication and joining. They can be easily welded using common techniques, making them versatile and cost-effective for various construction projects. In addition, these bars exhibit good corrosion resistance, making them suitable for use in environments where exposure to moisture or corrosive substances is a concern. This property helps to extend the lifespan of the bars and reduces the need for frequent maintenance and replacement. Moreover, carbon-manganese alloy steel round bars are generally more cost-effective compared to other high-strength steel options. They offer a balance between strength and affordability, making them a cost-efficient choice for applications where high-strength materials are needed without excessive costs. Lastly, these bars are relatively easy to machine, allowing for precise shaping and finishing. This feature makes them suitable for applications that require complex or custom designs. Overall, the advantages of using carbon-manganese alloy steel round bars include their strength, durability, impact resistance, weldability, corrosion resistance, cost-effectiveness, and machinability. These properties make them a reliable and versatile choice for a wide range of applications in industries such as construction, automotive, and manufacturing.

Send your message to us

AISI A2 Mould Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords