AIR FILTER BFC-4000 5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

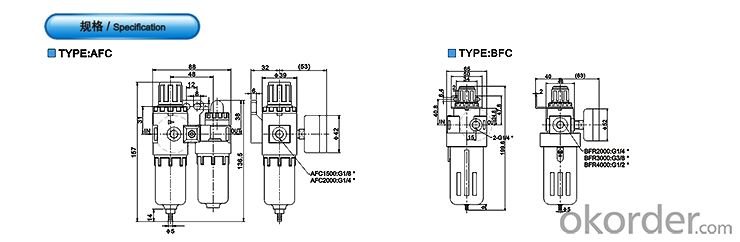

AFC\BFC Series

TYPE

small size

middle size

Joint pipe bore

1500:G1/8"

2000:G1/4"

3000:G3/8"

4000:G1/2"

Drian Type

Blank: Differential Drain

D: Automatic Drain

CERTIFICATE: ISO9001:2000 QEC CE

MAX PRESS: 9.9kg/c㎡

ADJ RANGE: 0.5-9.0kg/cm²

- Q: What is the difference between pneumatic components PC8-03 and PC8-02?

- 3 point teeth, PC8-02 refers to the 8MM trachea, 2 points of the teeth, the difference is that the two screw teeth.

- Q: Pneumatic components, characters, symbolsMuffler, throttle valve, cylinder, pneumatic valve, etc.

- Pneumatic valve: 2 2 valve /2 3 valve /3 4 valve /3 5 valve / valve / quick exhaust valve / dual pressure valve / adjustable one-way throttle valve / pressure sequence valve / vacuum control valve / delay valve, normally open / delay valve, often closed / gas control valve / stepping module, TAA

- Q: It is a standard pneumatic drive element. What functions does it have on the cylinder?

- (2) the cause of cylinder wearUnder normal conditions, the wear of the cylinder along the working surface in the piston ring moving region is an irregular cone with an upper, lower and lower height. The location of the maximum wear is the piston stop position on the wall, the first piston ring corresponding to the. The upper piston ring and the cylinder wall does not contact the almost no wear formed obvious cylinder shoulder.

- Q: Pneumatic oil filter oil in what

- Pneumatic filter (also known as oil-water separator), the role is to filter out from the compressed air source of water, oil, gas, dust impurities, so that air purification of pneumatic components. Transparent cup on the device (you can refer to, is not) inside the gas, impurities is filtered by the temporary storage. There are too many filters that need to be removed.

- Q: I used the ACE 2013 edition, how can I call the components of the library pneumatic components and hydraulic components, ah, how can I not call ah?. Thank you!

- Relay contacts or auxiliary contacts must be directly connected to the circuit to function, of course, by the number and location of the restrictions.

- Q: What are the common pneumatic components?

- Oil pressure buffer, precision speed stabilizing device, cylinder, electromagnetic valve, etc..

- Q: Pneumatic components generally used in what industry?

- An element that works by force of pressure or expansion of a gas, the component that converts the elastic energy of a compressed air into kinetic energy.

- Q: Why is there any white thing on the outer thread of the pneumatic element PC?

- It is a raw material belt used to seal and prevent leakage.

- Q: In turn, the pneumatic components follow the inlet direction. Why?

- The function and function of the pneumatic triplex is to purify the air source of the compressed air and then use it to the equipment. Pneumatic triplex according to the direction of intake are: oil filter (filter compressed air) - pressure reducing valve (to pass through the gas pressure drop) - oil mist (for oil atomization).

- Q: Development prospect of pneumatic technology

- Through the adjustment of product structure and improvement of operation and management, China's pneumatic industry has maintained good economic performance since the late 1990s, and produced steady and sustained growth. Because of its advantages of energy saving, pollution-free, high efficiency, low cost, safety and reliability and simple structure, it is widely used in various machines and production lines. The expansion of application of pneumatic technology is the sign of pneumatic industry development. The application of pneumatic components mainly includes two aspects: maintenance and matching. In the past, the sales of domestic pneumatic components were used for maintenance, and in recent years, the sales share directly as the main supporting parts increased year by year. The use of domestic pneumatic components, from tens of thousands of dollars worth of metallurgical equipment to only 1~2 hundred yuan chair. Railway switches, locomotive wheel rail lubrication, train brake, street cleaning, hoisting equipment in special workshops, military command vehicles, etc., have been specially developed domestic pneumatic components. This shows that pneumatic technology has penetrated into all walks of life and is expanding.

Send your message to us

AIR FILTER BFC-4000 5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords