AIR FILTER BFC-4000 3/8

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

· Air source treatment unit includes filter regulator and lubricator, It is in standard modular design and can freely separate and combine.

· Filter adopts novel vane design with high division efficiency and differential pressure discharge device. It can discharge water automatically.

· Regulator valve adopts balanced inlet structure with the advantages of stable pressure, high precision, and quick reaction.

· Lubricator is an element that can provide good lubrication for pneumatic system, with novel structure and easy adjustment of oil drip.

AIRTAC Air Filter Combination AFC2000 FR.L With Pressue Gauge

BFC2000 Two-point Combination Filter&Regulator Lubricator Air Units

BFC 3000 air combination filter regulator lubricator pressure regulator pneumatic component air unit air compressor

1/2'' BFC4000 Adjustable Pressure Air Source Treatment Unit

Air Source Treatment Air Filter Pneumatic Regulator Lubricator 0.5-9.0Kgf/cm2

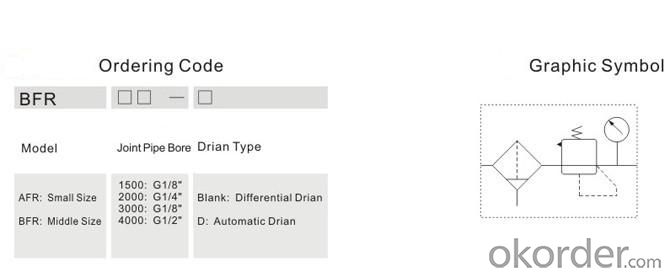

Ordering code:

Specification:

We manufacture all important parts by ourself to insure the quality, such as filter core. Outsourcing parts were selected and tested very strictly. Auto Drain can be selected.

- Q: What is the control principle of the pneumatic three jaw chuck? How does the pneumatic component control the chuck, then how does the chuck connect to the spindle? If a satisfactory answer will chongxie! most

- You can only answer your previous question. How does the pneumatic component control the three jaw chuck?:The three jaw chuck is also a kind of cylinder, but the connecting rod is added to the piston rod of the cylinder to form two claws or three claws.So the pneumatic component is the principle of controlling the air claw, the same as the principle of controlling the cylinder

- Q: How do pneumatic components sell well?

- The characteristic of the pneumatic industry is that you can laugh until you live

- Q: What are the requirements of the pneumatic system for compressed air?

- It is important to note that..:Can not directly use the air compressor of the compressed air, compressed to contain a certain amount of moisture in the air, oil and dust, compressed air temperature as high as 140 to 170 degrees Celsius, water and oil gas can become.You must use the compressed air purification: general machinery and general pneumatic loop filter precision <40 m; logic components, components, gas jet motor filter precision <10 m; food, medicine, electronics, air bearings and other precision <5 m filter.

- Q: Air compressor pneumatic three element

- Compression method:1) isothermal compression: a method of compressing a gas when it is compressed to maintain constant temperature.2) adiabatic compression: an adiabatic method that neither heats nor takes heat away from the outside.3) the compression of the multilateral curve (the actual compression method): it is a method of compressing a part of the heat produced by the heat exchange, which is different from that of the isothermal and adiabatic compression.

- Q: What are the components of a cylinder in a pneumatic system?

- The act or function of performing pneumatic system designs.

- Q: How much is the dynamic pressure gas picks

- Pneumatic instrument lathe is changed from manual pneumatic, the size of each plate and a cylinder with PLC or relay to control the on-off of the electromagnetic valve, and solenoid valve control cylinder work instead of manual operation, accessories to sell pneumatic components are, as for the effect depends on what you want to do is what kind of a workpiece.

- Q: What elements are most common in pneumatic?

- The most common should belong to the jointOur company specializes in the production of high-end white connector, CNC lathe

- Q: What are the classifications of cylinders in pneumatic components?

- The cylinder is one of the most widely used pneumatic actuators in pneumatic systems. Depending on the conditions of use, the structural characteristics of different, the use of different functions, installation of different forms are classified as follows:

- Q: What are the advantages of pneumatic components?

- Advantages of pneumatic components:1 、 pneumatic device simple structure, light, simple installation and maintenance. Medium for the air, compared to the hydraulic medium is not easy to burn, so the use of safety.

- Q: What are the parts of a pneumatic system?

- Pneumatic pressure control system consists of signal and power is composed of two parts, signal control part for driving the Wuxi smart precision valve pneumatic power in action. The pneumatic power part is represented by loop means to indicate the correlation between pneumatic components of different functions.

Send your message to us

AIR FILTER BFC-4000 3/8

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords