AIR FILTER BFC-4000 1/2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

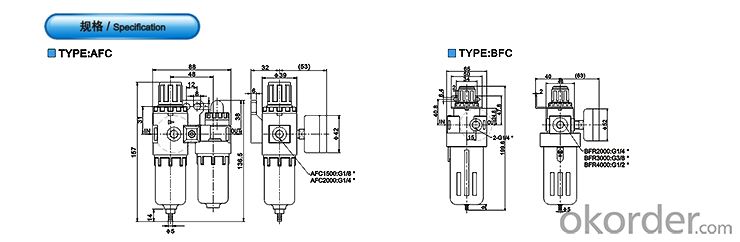

AFC\BFC Series

TYPE

small size

middle size

Joint pipe bore

1500:G1/8"

2000:G1/4"

3000:G3/8"

4000:G1/2"

Drian Type

Blank: Differential Drain

D: Automatic Drain

CERTIFICATE: ISO9001:2000 QEC CE

MAX PRESS: 9.9kg/c㎡

ADJ RANGE: 0.5-9.0kg/cm²

- Q: Acting as pneumatic component 60I've been selling pneumatic parts for three years

- If you are a regular dealer, you can consider doing it, but the funds settlement method should be discussed well.

- Q: What is the 3 position 5 way valve? And the relation between the cylinder and the pneumatic component and the valve

- Gases and liquids are collectively referred to as fluids. Fluid transmission and control are widely used in factories, such as large presses, hydraulic shears, and relatively sophisticated robotic hand operated by servo valves

- Q: What is the difference between pneumatic components PC8-03 and PC8-02?

- PC8-03 PC8-02 is the most common pneumatic component, which is commonly known as an upright joint. PC8-03 refers to the trachea of 8MM

- Q: Can nitrogen be used as the source of air for pneumatic valves? Generally use compressed air as pneumatic components of the gas source, suddenly asked customers can use nitrogen

- Upstairs answer a little problem, nitrogen gas can be made, but to select fluid valve!

- Q: Why does the pneumatic element contain no copper and does not contain polytetrafluoroethylene?

- So, most of them are using aluminum alloy more; as for PTFE, not very understanding, is afraid of the pneumatic seal interference, more than, please refer to;

- Q: Pneumatic components, three bit, five - way, can you explain?

- AB is not power when the 1 position, and here are divided into: three bit middle seal, three bit medium pressure, three bit discharge three (coil is not connected, when the spool stops position, P port and AB port connection)

- Q: What is the gas in the two pneumatic combination?

- GB brand: 7 mechanical lubricants (viscosity about 7E degrees) is also a relatively convenient choice. The oil mist can be ejected into the pipeline about 2M or so. And after the oil mist lubrication, it will be discharged with the valve, not in the cylinder memory.

- Q: What does pneumatic component mean?

- If pneumatic components are to be designed, some knowledge of fluid mechanics and aerodynamics must be understood. Design gas, pneumatic components, not just a hole, gas flow past so simple

- Q: How much is the dynamic pressure gas picks

- Most of the work pressure on the use of pneumatic equipment in the industry is about 0.55Mpa. (i.e.: 5.5kg/cm2 or so).

- Q: In turn, the pneumatic components follow the inlet direction. Why?

- Finally, according to the needs; is the oil mist by setting the lubricating oil mist cup extraction well mixed with compressed gas injection into mist gas, together into the pneumatic pipeline system for pneumatic components for lubrication. Therefore, the pneumatic components of these three functions must be carried out in this order.

Send your message to us

AIR FILTER BFC-4000 1/2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords