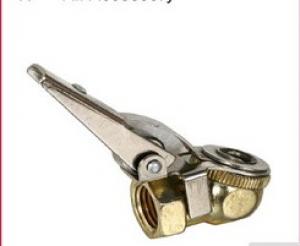

Specifications

pneumatic muffler

1.standard: Metric, Inch,NPT

2.tube size:04~16mm

3.thread size: M5~1/2"

4.stock available

pneumatic muffler

Features :

A.This serial silencer is used to reduce the dynamic noise for the pneumatic components or device exhaust.

B.They may directly mounted in the port of components or device with compact size,easy installation and high nose reduction result.