Plastic Pneumatic Silencer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | 1)package: with it logo on inner box,outside carton without any logo;2)OEM: without any logo; 3)Clients designed packages |

|---|---|

| Delivery Detail: | 2-30 days |

Specifications

1.Plastic silencer.

2.Working pressure:0-1.0MPa

Features:

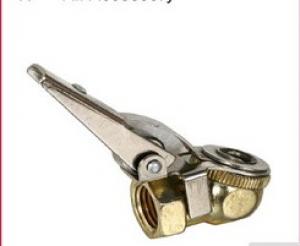

A.Convenient one touch fittings provide instant tubing connections.

B.Elliptical release ring facilitates pneumatic installations in confined spaces .

C.Light manual pressure on the elliptical release ring is all that is required to instantly disconnect each tube-no special tools

required .

D.Nickle-plated brass threaded bodies ensures anti-corrosion and anit -contamination.

- Q: What is the 3 position 5 way valve? And the relation between the cylinder and the pneumatic component and the valve

- 3 position 5 way valve means three reversing position, five inlet and outlet or air inletPneumatic components include cylinders and valves etc. the cylinders are of the original execution. The valves include pressure control valves, flow control valves, directional control valves, stop valves, and so on

- Q: What is the oil in the cylinder in the pneumatic original?

- Pneumatic components, oil mist is the use of flowing compressed air and lubricating oil mixture, spray into a fog like gas into the cylinder, air motor, air valve and other pneumatic components

- Q: Will the gas in the gas path corrode the pneumatic components after passing through the oil sprayer?

- The oil in the fog is usually added with turbine No. 1, which is a special oil for pneumatic system.

- Q: Such as pneumatic machines, pneumatic stamping machine, please ask where it came from, how come, I saw a few pipes connected to a small machine, is that pneumatic valve? As long as you buy that, will it work?

- 2, solenoid valve is an electromagnetic control of industrial equipment, is used to control the automation of the basic components of the fluid, is an actuator, not limited to hydraulic, pneumatic. Used in industrial control systems to adjust the direction, flow, speed, and other parameters of the medium. Solenoid valve with different circuits to achieve the desired control, and control accuracy and flexibility can be guaranteed. There are many kinds of electromagnetic valve, different electromagnetic valve in the control system at different locations to play a role, the most commonly used are one-way valve, safety valve, directional control valve, speed control valve;

- Q: It is a standard pneumatic drive element. What functions does it have on the cylinder?

- I. cylinder wear failureThe cold start was pounding percussion sound, temperature, noise reduced or disappeared.Cylinder depression.Sometimes the exhaust pipe exhaust smoke, add oil at the mouth of blue smoke.

- Q: I used the ACE 2013 edition, how can I call the components of the library pneumatic components and hydraulic components, ah, how can I not call ah?. Thank you!

- A storage unit in which the PLC software element corresponds to the memory of a computer. The status of the soft components can be directly queried in the same PLC.

- Q: What are pneumatic components?Pneumatic components include:

- The mechanical energy that converts compressed air pressure, reduced energy, and elastic energy into various kinetic energy.

- Q: Pneumatic components, those equipment needs to be used, specific points. Additional reward

- When it comes to pneumatic components, first of all, cylinders, valves, and such actuators can be used on almost all machines, because you're mechanical,

- Q: What about leakage of pneumatic components?

- Of course, part of the die-casting cylinder, it can not change seals it (open it will not go back)

- Q: What is the function of the oil sprayer in the pneumatic components, such as the AIRTAC model of AL2000?

- The oil sprayer in pneumatic components is mainly to pneumatic components behind the pipe,

1. Manufacturer Overview

| Location | Zhejiang,China (Mainland) |

| Year Established | 2000 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | NINGBO,SHANGHAI |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

Plastic Pneumatic Silencer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords