Specifications

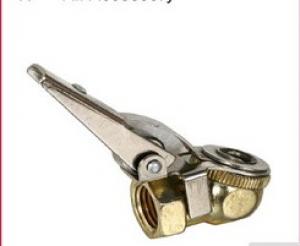

brass silencer(Silencers Silencer, Muffler, Exhaust Muffler, Exhaust Silencer, Plastic Silencer, Brass Silencer, Pneumatic).

brass silencer Compact design allows easy installation in narrow space

Features:

A.Convenient one touch fittings provide instant tubing connections.

B.Elliptical release ring facilitates pneumatic installations in confined spaces .

C.Light manual pressure on the elliptical release ring is all that is required to instantly disconnect each tube-no special tools

required .

D.Nickle-plated brass threaded bodies ensures anti-corrosion and anit -contamination.