Corrugated roofing sheets roll forming machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated roofing sheets roll forming machine Parameters :

No. | Spc. | |

1 | suitable material | Color Steel plate, galvanized sheet |

2 | Feeding width | 1000mm//1200mm/1250mm or customized |

3 | Rows of rollers | 16-18rows |

4 | Main power | 5.5kw |

5 | Hydraulic power | 4kw |

6 | Thickness of raw material | 0.2-1.25mm |

7 | Transportation system | Chain transportation |

8 | Thickness of chain | 1.2 inches |

9 | Effective Width | 800-1100mm or customized |

10 | Out diameter of shaft | 80mm (solid shaft) |

11 | Material of shaft | 45# steel forged by the Carbon at high temperature |

12 | Roller material | 40Cr steel polished and coated with chrome HRC55-60° |

13 | Shear mould | Cr12 |

14 | Voltage | 380V 50Hz/60Hz 3phases |

15 | Control system | PLC Frequency Control System with touch screen |

16 | Toal Weight | 7 tons |

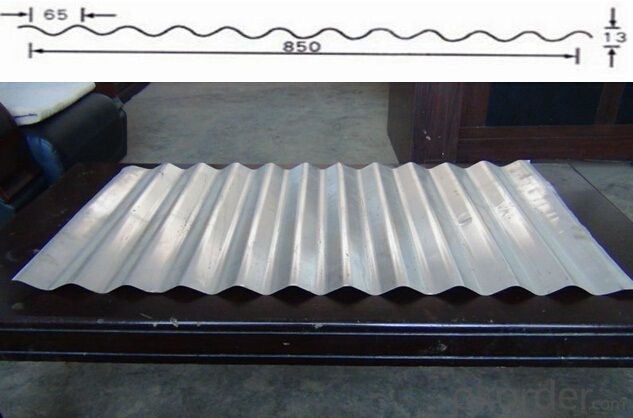

Corrugated roofing sheets roll forming machine types:

Type | Input | Output | Plate Thickness |

LS-1250-1100 | 1250mm | 1100mm | 0.4-0.8mm |

LS-1200-1000 | 1200mm | 1000mm | 0.4-0.8mm |

LS-1000-860 | 1000mm | 860mm | 0.4-0.8mm |

LS-1000-840 | 1000mm | 840mm | 0.4-0.8mm |

LS-1000-828 | 1000mm | 828mm | 0.4-0.8mm |

LS-1000-828-25 | 1000mm | 828mm | 0.4-0.8mm |

LS-1000-800-35 | 1000mm | 800mm | 0.4-0.8mm |

LS-1000-800-33 | 1000mm | 800mm | 0.4-0.8mm |

LS-1000-820 | 1000mm | 820mm | 0.4-0.8mm |

- Q: What are the shortcomings of traditional machining?

- Low efficiency, high cost, batch processing, then the processing quality is not stable, the accuracy is not high, labor intensity, processing staff, frequent processing times, and now good equipment to complete the car, drilling, milling and other processes.

- Q: Information on building materials decoration.

- Equipment Construction Projects Cooperation Adhesives Metal Building Materials Insulation Materials Building Materials Door and Window Wall Materials Wood Sheet Other Building Materials Products Construction Materials Stone Stone Lime, Gypsum Plastic Building Materials Locks Ceramic Processing Machinery

- Q: Information on building materials decoration.

- What are the building materials industry? Wallpapers Flooring Pallet Handling Machinery Fireproof Materials Waterproof and Moistureproof Materials Heat Absorbing Sound Absorbing Materials Pipe Fittings Concrete and Products Activities Furniture Manufacturing Machinery Building Materials Processing Building Glass Construction Related Equipment Construction Project Cooperation Adhesive Metal Building

- Q: Classification and components of hydraulic press

- According to the application of equipment, hydraulic equipment can be divided into many types, such as machine tool hydraulic equipment, plastic molding processing hydraulic equipment, engineering machinery hydraulic equipment, steel metallurgy hydraulic equipment, building materials processing hydraulic equipment.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- Can not exchange what ah, I just graduated from a mechanical professional and then a large state-owned enterprises, do machine processing, feeling, too buried no talent, and their own pro-prog have all very skilled, the results should be forgotten, can not give the younger

- Q: Main classification of hydraulic machinery?

- (4) According to the importance of equipment in the production system or application classification, hydraulic equipment can be divided into key equipment, key equipment and general equipment.

- Q: What gear is machined out of the gear?

- The bevel gears are laid on the planer. Spiral bevel gears - forming end mills.

- Q: What is the principle of the cutting order in machining?

- In the arrangement of mechanical cutting process, should be based on the processing stage of the division, the choice of benchmarks and the surface to be processed to decide, generally should follow the following principles:

- Q: What are the aspects of the mechanical processing quality

- The so-called machining precision refers to the actual geometric parameters (size, shape and surface of the mutual position between the workpiece) and the ideal geometric parameters of the degree of compliance. The higher the degree of compliance, the higher the machining accuracy.

- Q: What are the oyster processing companies?

- other electronic processing metal processing including | casting pressure processing welding and bonding heat treatment cutting sheet metal processing Electroplating processing CNC and CNC machining line cutting processing other metal processing glass processing ceramic processing rubber processing including rubber rolling processing rubber molding processing rubber post processing processing other rubber processing plastic processing including injection molding extrusion processing blow molding processing plastic processing plastic processing casting Plastic Processing Plastic Surface Treatment Other Plastic Processing Textile Processing Including Spinning Processing Weaving Processing Dyeing & Finishing Quilting Processing Embroidery Processing Hand Knitting Processing Other Textile Processing leather processing entertainment leisure products processing health care products processing business printing processing including brochures

Send your message to us

Corrugated roofing sheets roll forming machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords