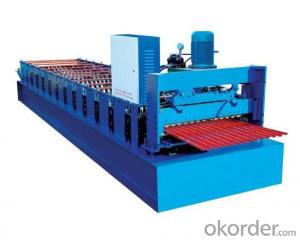

Roll forming Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 25 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Roll Forming Machine

Packaging Details: | main body of the machine naked into the containers, covered with the plastic film. spare parts in the wooden box |

Delivery Detail: | within 30 working days after received deposit |

Specifications of Roll Forming Machine

Best quality aslo with reasonable price

we provide the technical support for whole life of the machine

Forming machine parameter of Roll Forming Machine

Feeding width: 1000mm

Thickness: 0.3-0.8mm

Machine dimension: 5000mm×1300mm ×1200mm

Motor power: 3.0KW

Hydraulic station power: 3 KW

Production line speed: 4-6m/min

Machine weight: 1.9 T

Forming row: 9 stands

Roller: casting iron

Voltage: 380V/50-60HZ

Shaft, axis: φ75

Medium plate: 14mm

Main frame: 300 H steel

- Q: What steps are required during the installation of the cement tile machine?

- Host installation: the user in accordance with the size of the foundation map dug the foundation, according to the requirements of the drawings for the foot of the embedded hole or under the embedded iron with concrete pouring, for the installation of embedded holes into the anchor bolts (M24 × 360) and then Grouting, embedded iron can be a one-time cast into the installation and direct welding with the host, based on the plane must be level, the smaller the better the better.

- Q: Analysis on the Problems of Cement Shade Machine

- Pan alkali base water, alkali or salt content is too high, the water vapor will bring out the salt and the bottom of the film or surface precipitation; tile body alkaline, in the water after the alkali will be discharged through the pores, the formation of small bubbles. Remove all the affected and the loss of adhesion of the film, to be fully dry tile body, treated with oxalic acid and washed with water, dry and then brushing; follow the construction specifications, do grass-roots waterproof, to ensure that the substrate conditions meet the construction requirements. Gloss uneven uneven base layer is not uniform, the adsorption of the film is not high; film thickness is not uniform; the same side using different construction tools; the same side using different batches of products.

- Q: The processing method of the tile machine

- Mold release agent spray too little. Can be appropriate to increase the fuel injection pressure. The center of the tile plate is partial.

- Q: What are the advantages of cement tile machine?

- equipment investment, fast, high yield. More ordinary molding color tile molding unit: high technical content, fast, high yield (single class production increased by 80%), high product efficiency, good market prospects.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | Eastern Europe 6% Southeast Asia 15% Africa 4% Mid East 15% Domestic Market 60% |

| Company Certifications | ISO 9001:2008;CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Roll forming Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 25 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords