Advanced Construction Materials Aluminium Exterior Wall Aluminum Composite Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Advanced Construction Materials Aluminium Exterior Wall Aluminum Composite Panels Description:

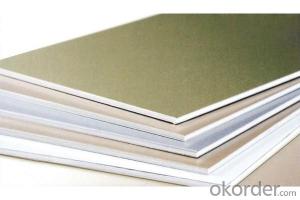

Aluminum Sandwich Panel is a structure made of three layers: low density core inserted in between two relatively thin skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

2.Main Features of the Advanced Construction Materials Aluminium Exterior Wall Aluminum Composite Panels:

Superior weather, corrosion, pollutant resistance

Even coating, various colors

Fireproof, excellent heat and sound insulation

Superior impact resistance

Lightweight and easy to process

Easy to maintain, self-clean

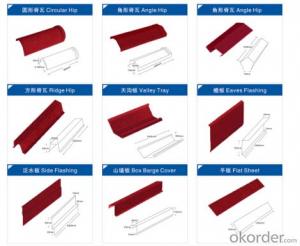

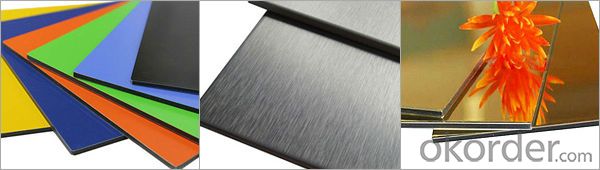

3. Advanced Construction Materials Aluminium Exterior Wall Aluminum Composite Panels Image:

| Our product image | ||

| ||

| PVDF aluminum composite panel | PE aluminum composite panel | Unbroken aluminum composite panel |

| ||

| Fireproof aluminum composite panel | Brushed aluminum composite panel | Mirror aluminum composite panel |

| Our factory |

|

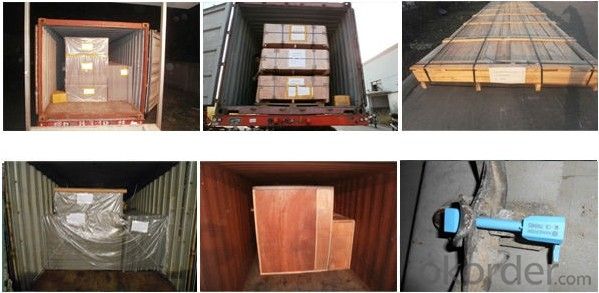

| Our package |

|

4. Advanced Construction Materials Aluminium Exterior Wall Aluminum Composite PanelsSpecification:

Width | 1000mm /1220mm /1250mm /1500mm /1550mm /1570mm |

Length | 2440mm /3200mm /4000mm /5000mm /6000mm(Max), or customized |

Thickness | 2mm / 3mm / 4mm / 5mm / 6mm (3mm and 4mm are most popular) |

Thickness of ALU-layer | 0.08mm,0.10mm,0.12mm,0.18mm,0.20mm,0.25mm,0.30mm,0.35mm,0.40mm,0.45mm,0.50mm |

Inner Core | Normal non toxic PE core, one side unbroken plastic, two side unbroken plastic, virgin LDPE, fireproof material |

Color | Solid color, metallic color, brush color, mirror, marble, wooden color, glossy |

Brand | OEM |

Surface | PE coating , PVDF coating, NANO, Brush surface, mirror surface |

Thickness of film | 0.07mm,0.09mm |

Packing | 1220*2440*4mm 1500 sheets in 1*20’ft container, nude packing; wooden pallet package for LCL. |

5.FAQ:

1) How about your quality?

According to international test standard, all the tested items are satisfied with high-class.

2).What are your certificates?

GB/T17748-1999 and ISO9001, SGS, CE etc.

3) How about your delivery time?

Within 15 working days after receiving deposite.

- Q: What are the qualifications of aluminum-plastic panels on the external walls? anxious

- Three enterprises: can bear the amount of individual contract does not exceed 5 times the registered capital of enterprises and individual projects in the 3000 square meters and below the height of 30 meters and below the construction of the curtain wall works.

- Q: The difference between aluminum and aluminum veneer

- Metal plate curtain wall applications have been a few decades of history, is still in use, including aluminum veneer, aluminum composite panels and aluminum honeycomb panels in three of these three materials, the most commonly used is the aluminum veneer and Aluminum panels. Aluminum veneer appeared the earliest, and later in the late 60s and early 70s, aluminum-plastic composite panels invented in Germany, and quickly popular around the world.

- Q: Can the foamed cement composite board paste the aluminum plate?

- We are aluminum-plastic plate manufacturers, paste the practice of commonly used substrate is not dense dust.

- Q: Aluminum-plastic plate and color steel tile which is more durable

- Outdoor color steel tile better

- Q: 3d board and aluminum plate prices? What kind of price?

- Three-dimensional board, including polymer composite board, aluminum plate, color plate and other molding materials, in general, polymer composite board, aluminum plate are in the price is higher than the aluminum-plastic plate.

- Q: Rush! What is the glue between aluminum and plastic?

- E-MA-AA, manufactured by ExxonMobil, USA. Bonding effect is very good! There is a need to contact OKorder Jinke Chemical Co., Ltd.,

- Q: Will the Pacific bird now use which aluminum-plastic plate

- As well as clothing class seven wolves, Qipai, this reputation Aiyilian and so on.

- Q: Curtain wall sun room stone hit glass hit wood carpentry workers

- In the aluminum-plastic plate and tempered glass combination of the shed and the brick wall joints at the joints, to ask the waterproof workers to do, because the glue treatment can only be about a year, because the plastic dry after the stretch , Can not fundamentally solve the problem! Need several kinds of materials used in order to cure!

- Q: Aluminum-plastic plate production process is toxic, which I found on the Internet: aluminum-plastic composite panels are made of multi-layer composite material, the upper and lower layers of high-purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE ) Core board, the front also paste a layer of protective film. For outdoor, aluminum-plastic panels coated with fluorocarbon resin (PVDF) coating, for the interior, the front can be non-fluorocarbon resin coating.

- In addition, after all, aluminum-plastic plate coating is a paint, it requires chemical solvents, this paint is volatile, smell weird. As for the size of the toxicity is hard to say.

- Q: RT, I think these two are not the same thing? But, it seems not, we take this to do the printing, and now use the composite aluminum-plastic plate, but UV inkjet, will be out, others use aluminum Plastic composite panels, will not fall, so I think these two are not the same thing, please give guidance, these two kinds of relations, why, ...

- These two kinds of things is a kind of material is the aluminum composite plate you will be sprayed out because you use the paint is not dedicated so it will fall If you want to spray the other side of the original aluminum coating on the color can not afford to suggest you Consult you to buy the manufacturers so that he can not provide you with the raw materials do not go to the market to buy a common inkjet paint that is not because the aluminum-plastic plate on the coating and then spray something but not to go through a special treatment of paint can Otherwise it will not be how long it is best to dry from the dry paint

Send your message to us

Advanced Construction Materials Aluminium Exterior Wall Aluminum Composite Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords