Metal Aluminum Composite Panel Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Adopt high-quality aluminum alloy real materials with standard mould, make the ceiling tile install soomth and easy.

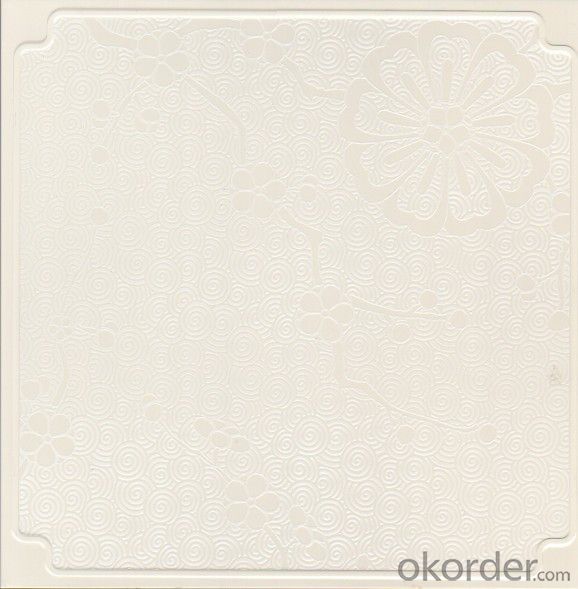

Adopt high quality and ECO-Friendly surface treatment technologies, such as wooden/stone color coated, spray painted, etc., make the ceiling tile beautiful and matching to various spaces.

Product Applications:

♦ Supermarkets, Shopping malls, Shops.

♦ Outdoor facilities, Gas station, Toll station.

♦ Subway Station, Railway Station, Bus station, Airport.

♦ Schools, Offices, Meeting rooms, bookstores. Stadiums.

♦ Building lobby, Corridors, Toilets.

♦ Supermarkets, Shopping malls, Shops.

♦ Outdoor facilities, Gas station, Toll station.

Product Advantages:

1.Durability:

Good materials and sophisticated fabrication technology ensure durability of ceilings throughout their lifespan;

2.Environmental:

Aluminum ceiling does not contain harmful substance to environment. The aluminum alloy is recyclable and reused;

3.Sound absorbing:

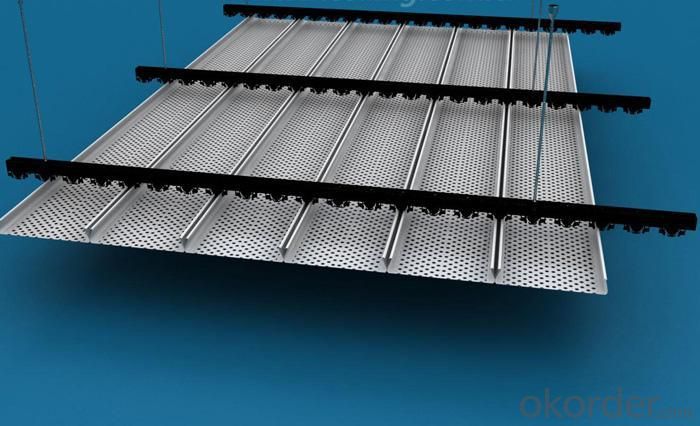

Sound absorption function will be increased vastly by perforated holes and non-woven fabric, which is anti-inflammable;

Main Product Features:

(1)Clip-in aluminum ceiling is made from high quality aluminum panels (0.6mm-1.2mm thick).

(2) International standard 1100H24, 3003H24, or 5005H24 aluminum alloy depending on requirements; galvanized iron and stainless steel are made available as well.

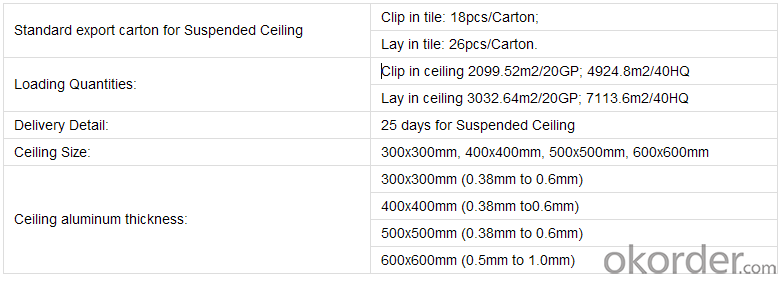

Product Specifications:

FAQ:

Q1: Is your company a manufacturer or a trading company?

A: We are a professional metal building material manufacturer with the advantage of direct and consistant quality control, more competitive pricing and smooth services. We welcome to visit our company and manufacturing site located in Shanghai, China and hope that we can foster a long-term business relationship with you.

Q2: What if I cannot find a desired model in your catalogue or online product displays?

A: With 20 years of experience in landscape projects, we are experienced and expertised to make customized products according to different designing needs. The catalogue only includes part of our standard models. Just tell us what you want to achieve or give us your drawings, and we will find a solution for you.

Q3: What is your accepted payment terms?

A: We prefer T/T,Westunion,and Paypal. We are open to the negotiation about payment terms with our clients before signing up the contract.

Images:

- Q: I stood a piece of the shop when the remaining aluminum-plastic plate plate, this aluminum layer even so, is auspicious brand, this is the situation, I do the store will fall off

- This brand of aluminum-plastic plate is now the difference is missing, quite a mixed bag.

- Q: How to adjust the length of the aluminum plate

- Common is the length of the custom, the standard length of 2440 mm, that can be greater than or less than 2440 mm this length,

- Q: Who prawn know that there is no aluminum plate factory in Shenyang it? What is the best brand and contact phone, thank you first, huh, huh

- But the development of agents in Shenyang, the model is still quite a lot of manufacturers.

- Q: Home decoration, aluminum-plastic board in general how thick ah?

- Size is generally 1220 * 2440

- Q: Why do you stay 0.3mm plastic when processing aluminum-plastic composite board?

- Protect the aluminum skin is not directly exposed to the air, but also in the folding time is not easy to break

- Q: Aluminum-plastic plate roof is similar to the shape of many store signs, but the area is much larger times, like a box of the same, the middle of the keel or something, the other few are aluminum-plastic panels, combined into a cube. The most intuitive understanding of the container, or sealed the top of the truck compartment, surrounded by closed but the middle of the gap, so although the indoor water leakage point is fixed, and perhaps can not explain that only these leaks leak, there may be other places leaking , Because some points are low or just the seams are so leaked from these points. From this point of view, I do not know whether the need to clean up all the previous waterproof ointment, all re-silica gel?

- Aluminum plastic plate waterproofing You should pay attention to the aluminum surface is relatively smooth, waterproof glue must choose a little bigger viscosity, so as to seize the smooth aluminum, cracks, how wide, if more than 5mm will use non-woven fabrics to support the plastic , That is, first coated with a layer of non-woven layer of adhesive and then coated with a layer of glue, the first layer to be wider than the leakage 3 - 5cm. More economical waterproof ointment can solve the problem, the use of the adhesive surface must be kept clean, no water, sticky coating to choose the sunny afternoon high temperature period, so that the best use of waterproof ointment viscosity. There is no hole in the aluminum-plastic plate, where the seam is not leaking, and only fill the hole at the sewn.

- Q: How does the wood-resistant plastic plate produce?

- Plastic composite steel plate: it is in the steel or pressure plate covered with 02 ~ 04mm soft or semi-rigid PVC plastic film, single and double-sided coating two. With insulation, wear resistance, corrosion resistance, oil and other characteristics; do wall panels, roof panels.

- Q: Aluminum plate fire rating how to determine

- Aluminum plate fire rating is determined by two indicators, namely the national mandatory standard GB8624 "building materials combustion performance classification method" and GB / T17748 "aluminum composite panel" GB requirements.

- Q: What kind of material is it under these two? What's the difference?

- Aluminum composite panels are made of aluminum and aluminum composite materials, such as aluminum and aluminum honeycomb core composite honeycomb made of aluminum is a type of aluminum composite plate.

Send your message to us

Metal Aluminum Composite Panel Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords