Scotch Greener Packaging Tape with OPP Film Waterproof Adhesive Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

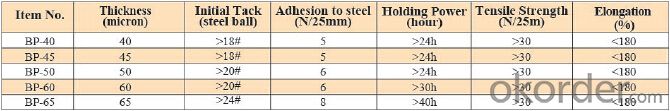

Typical Physical Reports of PVC Electrical Tape

Packaging

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1280mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Is packaging tape heat resistant?

- Indeed, packaging tape typically exhibits heat resistance. The composition of most packaging tapes involves materials like polypropylene or acrylic, which possess elevated melting points and can endure extreme temperatures. Thanks to this heat resistance, packaging tape serves diverse purposes, such as sealing boxes and packages that may encounter heat during transportation or storage. Nevertheless, it is crucial to acknowledge that the heat resistance of packaging tape may fluctuate based on the tape's brand and quality. Hence, it is advisable to review the product specifications or seek guidance from the manufacturer to guarantee the tape's appropriateness for the desired utilization and temperature circumstances.

- Q: Is packaging tape heat resistant?

- Yes, packaging tape is generally heat resistant. Most packaging tapes are made from materials such as polypropylene or acrylic, which have high melting points and are able to withstand high temperatures. This heat resistance makes packaging tape suitable for various applications, including sealing boxes and packages that may be subjected to heat during transportation or storage. However, it is important to note that the specific heat resistance of packaging tape may vary depending on the brand and quality of the tape. Therefore, it is recommended to check the product specifications or consult with the manufacturer to ensure that the packaging tape is suitable for the intended use and temperature conditions.

- Q: Does packaging tape come in different lengths for convenience?

- Yes, packaging tape does come in different lengths for convenience. Packaging tape is available in various lengths to meet the needs of different packaging tasks. The most common lengths of packaging tape are 55 yards (50 meters) and 110 yards (100 meters). These lengths are designed to cater to different packaging needs and ensure that there is enough tape to securely seal multiple packages without running out. Additionally, the availability of different lengths allows for flexibility in choosing the most suitable amount of tape for specific packaging requirements, ensuring convenience and cost-effectiveness.

- Q: Does packaging tape have a specific adhesive strength?

- Yes, packaging tape does have a specific adhesive strength. The adhesive strength of packaging tape refers to how well it sticks to surfaces. This strength is typically measured in ounces per inch (oz/in) or pounds per inch (lb/in). The adhesive strength of packaging tape is determined by various factors, such as the type of adhesive used, the thickness of the tape, and the quality of the backing material. Different types of packaging tape may have different adhesive strengths to cater to specific needs, such as lightweight packages or heavy-duty shipments. It is important to consider the intended use and the weight of the package when choosing packaging tape with the appropriate adhesive strength.

- Q: Can packaging tape be used on different materials?

- Yes, packaging tape can be used on different materials. Packaging tape is versatile and can adhere to a wide range of surfaces, including cardboard, plastic, metal, glass, and even fabric. It is designed to provide a strong and secure seal, ensuring that packages remain intact during transportation and storage. Whether you are sealing a cardboard box, bundling items together, or securing a package, packaging tape is an effective choice for various materials.

- Q: Can packaging tape be used for sealing construction or building materials?

- Yes, packaging tape can be used for sealing construction or building materials, but it may not provide the same level of durability and longevity as specialized tapes designed for such purposes.

- Q: What are the common sizes and lengths of packaging tape rolls?

- Individuals or businesses have different preferences and needs when it comes to the sizes and lengths of packaging tape rolls. However, there are a few standard options commonly found in the market. The width of most packaging tape rolls is 2 inches, or approximately 5 centimeters. This width strikes a good balance between adhesion strength and ease of application, making it suitable for general packaging purposes. As for length, packaging tape rolls come in various options. They can range from 55 yards, or approximately 50 meters, to 110 yards, or approximately 100 meters. The 55-yard length is considered standard and widely available, while the 110-yard length is known as a "jumbo" roll. People who require larger quantities of tape or frequently engage in extensive packaging tasks often prefer the 110-yard length. It's important to note that some manufacturers may offer packaging tape rolls with different dimensions to cater to specific needs. For example, there may be narrower or wider tapes available, such as 1.5 inches or 3 inches, to accommodate specific packaging requirements. Ultimately, the choice of size and length for packaging tape rolls depends on factors such as the volume of packaging tasks, the nature of the items being packaged, and personal preferences. It is advisable to consider specific needs and evaluate the best option accordingly.

- Q: Is packaging tape safe to use on plastic cutting boards?

- Yes, packaging tape is safe to use on plastic cutting boards. It provides a secure and durable sealing solution that effectively holds the plastic cutting boards together.

- Q: Is packaging tape easy to tear?

- Indeed, packaging tape is typically quite simple to tear. Numerous packaging tapes are specifically crafted to be torn effortlessly by hand, eliminating the need for scissors or any other tools. Typically, the tape incorporates perforated lines or a slightly thinner portion that enables straightforward tearing. This feature renders it convenient for swiftly sealing or opening packages without encountering any inconvenience. Nonetheless, the ease of tearing may differ based on the particular brand and caliber of the packaging tape.

- Q: Can packaging tape be used for sealing plastic toys?

- Indeed, one can utilize packaging tape to seal plastic toys. Engineered to possess strength and adhesive properties, packaging tape proves itself as an excellent choice for securing and sealing diverse materials, including plastic. By proficiently holding together the various components of a plastic toy, it guarantees the toy's preservation. Nonetheless, it is crucial to acknowledge that packaging tape may not possess the same visual appeal as other specialized tapes crafted exclusively for toy packaging, such as clear tape or decorative washi tape.

Send your message to us

Scotch Greener Packaging Tape with OPP Film Waterproof Adhesive Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches