Scotch Packaging Tapes with Good and Medium Quality - OPP Packing Tapes

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of OPP Packing Tape

OPP packing tape are made of BOPP films coated with acrylic adhesive.

Application of OPP Packing Tape

1. Industrial box parking

2. outside electronics product packing with safety material

3. gift wrapping &decoration

4. general purpose repair

5. bundling &strapping

6. stationery purpose

Advantage of OPP Packing Tape

1.Packing tape, superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of OPP Packing Tape

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100rolls/carton(according to different specifications)

carton size : any carton size as your request

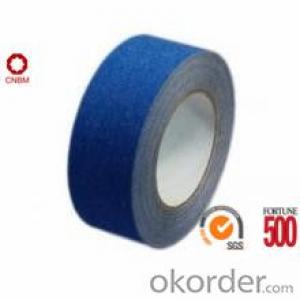

Pictures of OPP Packing Tape

Specification of OPP Packing Tape

| Material | OPP |

| Adhesive Side | Single Sided. |

| Adhesive | Acrylic, Water based acrylic adhesive |

| Acrylic | Water based acrylic adhesive |

| Color | Transparent clear/yellowish /tan brown/blue/red/ green |

| Normal thickness | 36mic, 38mic, 40mic, 43mic, 45mic, 46mic, 48mic,50mic, 52mic |

| Packaging | Single packed, shrink film packed, depend on customer’s request |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q: Can packaging tape be used for sealing plastic wrap?

- Typically, packaging tape is not employed for sealing plastic wrap. Its purpose lies in firmly sealing packages by adhering to cardboard and other surfaces. Conversely, plastic wrap is a thin, see-through film utilized to cover and safeguard food or other objects. It is usually sealed by pressing the edges together or utilizing a specific plastic wrap cutter. Although packaging tape may serve as a temporary seal, it is not intended for use with plastic wrap and may fail to provide a dependable or durable seal. It is advisable to adhere to the manufacturer's recommended method for sealing plastic wrap.

- Q: Can packaging tape be used for sealing arts and crafts materials?

- Packaging tape is indeed suitable for sealing arts and crafts materials. Its versatility as an adhesive enables it to effortlessly attach and secure a wide range of materials such as paper, cardboard, fabric, and more. Whether you need to seal envelopes, wrap gifts, or engage in art projects, packaging tape guarantees a sturdy and durable bond, ensuring the secure sealing of your arts and crafts materials. Moreover, its transparent nature allows it to seamlessly blend with your project, making it an exceptional option for sealing arts and crafts materials.

- Q: Does packaging tape come in different odor-free options?

- Yes, packaging tape does come in different odor-free options. Many manufacturers offer packaging tape that is specifically designed to be odor-free, making it suitable for use in sensitive environments or for individuals who may have allergies or sensitivities to certain scents. These odor-free options are typically made from materials that do not emit any strong smells or fragrances, ensuring a neutral and pleasant packaging experience. When purchasing packaging tape, it is always a good idea to check the product description or labeling to see if it is specifically mentioned as odor-free.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. However, it is important to consider a few factors before using it. Firstly, ensure that the paint on the furniture is fully cured or dried, as using tape on fresh paint may cause it to peel off. Additionally, check the type of paint used on the furniture, as some types may be more prone to damage or discoloration from adhesive tape. To be on the safe side, you can test the tape on a small inconspicuous area of the furniture first to see if any damage occurs. It is also recommended to remove the tape carefully and slowly to minimize the risk of any damage.

- Q: Is packaging tape safe to use on ceramic tiles?

- Yes, packaging tape is safe to use on ceramic tiles. It adheres well to the smooth surface of the tiles and does not cause any damage or leave any residue when removed.

- Q: Can packaging tape be used for sealing plastic or poly bags?

- Yes, packaging tape can be used for sealing plastic or poly bags. Packaging tape is specifically designed to provide a strong and secure seal on various surfaces, including plastic and poly bags. It has an adhesive backing that adheres well to the plastic material, ensuring that the bag remains tightly sealed. However, it is important to note that there are different types of packaging tape available, so it is recommended to choose a tape specifically designed for sealing plastic or poly bags to ensure optimal performance and long-lasting seal.

- Q: Does packaging tape have an expiration date?

- Packaging tape generally lacks an expiration date due to its composition of robust materials like polypropylene or PVC. These substances possess a lengthy shelf life and resist degradation over time. As long as the tape is stored in a cool, dry location, shielded from sunlight and extreme temperatures, it should retain its effectiveness for an extended period. Nevertheless, it is worth noting that the adhesive on packaging tape might lose its stickiness over time, particularly if exposed to heat or moisture. Consequently, although packaging tape may lack an official expiration date, it is advisable to utilize it within a reasonable timeframe to guarantee its adhesive properties remain intact.

- Q: Are there any specialty packaging tapes for specific applications?

- Yes, there are specialty packaging tapes available for specific applications. These tapes are designed to meet specific needs such as high strength, temperature resistance, moisture resistance, or delicate item protection. Examples include double-sided tapes, reinforced tapes, freezer tapes, and tamper-evident tapes. These specialty tapes offer enhanced performance and durability for specific packaging requirements.

- Q: Can packaging tape be used for securing cables or cords?

- Yes, packaging tape can be used for securing cables or cords. It provides a temporary solution for bundling and organizing cables, but it is not the most ideal or durable option. Using specialized cable ties or Velcro straps is recommended for a more secure and long-lasting solution.

- Q: Can packaging tape be used for sealing plastic toys?

- Indeed, one can utilize packaging tape to seal plastic toys. Engineered to possess strength and adhesive properties, packaging tape proves itself as an excellent choice for securing and sealing diverse materials, including plastic. By proficiently holding together the various components of a plastic toy, it guarantees the toy's preservation. Nonetheless, it is crucial to acknowledge that packaging tape may not possess the same visual appeal as other specialized tapes crafted exclusively for toy packaging, such as clear tape or decorative washi tape.

Send your message to us

Scotch Packaging Tapes with Good and Medium Quality - OPP Packing Tapes

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches