IPG Masking Tape Temperature Resistance 80 Colour Red World Top 500 Enterprise

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

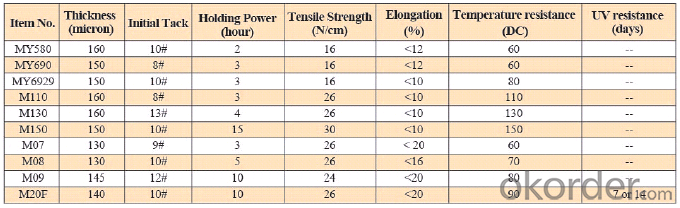

Typical Physical Reports of Masking Tape

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1800mm; width according to customers’ requirements

Cut Roll: As per customer’s requirements

Delivery Detail: within 10-12 working days after receiving your deposit

Service

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can definitely be used for other purposes besides packaging. Due to its strong adhesive properties and durability, it can be used for a variety of tasks. For example, it can be used for household repairs such as fixing a broken book spine or securing loose cables. Additionally, it can be used for crafting projects like creating temporary or permanent decorations, making durable envelopes, or even in DIY projects like creating makeshift labels or organizing items. Furthermore, packaging tape can also be used for temporary fixes, such as sealing small leaks or cracks in pipes or containers until a permanent solution is found. The versatility of packaging tape makes it a handy tool to have around the house or office for various purposes beyond just packaging.

- Q: Are there any special considerations when using packaging tape for fragile items?

- Special considerations must be taken into account when utilizing packaging tape for delicate items. To package fragile items appropriately, it is imperative to select a tape specifically created for this purpose. Seek out packaging tape that is clearly marked as "fragile" or "handle with care," as these tapes are commonly reinforced with added strength and possess unique features aimed at protecting fragile items. When using packaging tape for fragile items, certain specific factors should be considered: 1. Strength and durability: Fragile items necessitate additional protection, making it essential to employ a tape that is both strong and durable. Opt for packaging tape crafted from top-notch materials, such as reinforced fiberglass or heavy-duty polypropylene, to ensure it can endure weight and pressure without tearing or breaking. 2. Cushioning and padding: Fragile items are prone to damage from impacts, thus it is advisable to utilize packaging tape that provides cushioning or padding. Some tapes come with built-in bubble wrap or foam padding, which assists in absorbing shocks and safeguarding delicate items from breakage during transit or handling. 3. Adhesive quality: The adhesive quality of the packaging tape is another crucial consideration. Fragile items may require longer transit times, necessitating the tape to remain securely in place throughout the journey. Look for packaging tape with a robust adhesive that can adhere well to various surfaces, including cardboard boxes, plastics, or glass. 4. Easy removal: Delicate items often require gentle unpacking, thus utilizing packaging tape that is easily removable, without leaving any sticky residue or causing damage, is essential. Some tapes are designed with a low-tack adhesive, making them simpler to peel off without any inconvenience. 5. Clear visibility: It is vital to ensure that fragile items are unmistakably marked to notify handlers and delivery personnel. Utilizing brightly colored packaging tape or tape labeled with a "fragile" message can effectively attract attention and promote careful handling. In conclusion, when employing packaging tape for fragile items, it is crucial to select a tape that possesses strength, durability, cushioning, a high-quality adhesive, and easy removal properties. These considerations will help safeguard delicate items from damage during shipping or handling.

- Q: Is packaging tape transparent?

- Yes, packaging tape is usually transparent.

- Q: Is packaging tape safe for use on children's toys or products?

- Packaging tape is not recommended for direct use on children's toys or products. While packaging tape is commonly used for sealing and securing packages, it is not designed or tested for contact with children's skin or for use on items that may come into direct contact with their mouths or eyes. Children's toys and products are subject to specific safety regulations and guidelines to ensure they are safe for use and do not pose any harm to children. It is important to follow the manufacturer's instructions and use appropriate materials that are specifically designed for children's toys and products, such as non-toxic adhesives or child-safe tapes, to ensure the safety of children.

- Q: Has anyone done a tape cut? What about profit?

- I do not know where you belong, but the overall profit is not high, if it is sold to dealers, profits are generally 2.5 to 3 cents a square or so (not deducted from the cost)

- Q: How does packaging tape perform on high-gloss surfaces?

- High-gloss surfaces are well-suited for packaging tape, as it excels in its performance on such surfaces. The adhesive used in packaging tape is specifically formulated to adhere to a wide range of materials, including glossy surfaces like plastic, glass, or coated paper. By creating a strong bond, the tape ensures the package remains securely sealed. It firmly sticks to the high-gloss surface, preventing any peeling or shifting during transport or storage. Furthermore, packaging tape typically possesses moisture resistance, further enhancing its effectiveness on glossy surfaces. In conclusion, packaging tape offers a reliable and professional solution for sealing packages on high-gloss surfaces, guaranteeing security and protection.

- Q: When the box is sealed, the tape is very noisy and very harsh. What shall I do?

- Because the peeling force is quite light, the friction is small, so there is no sound, and the ordinary adhesive tape will be noisy when it is torn!Also called peeling tape, some

- Q: Is packaging tape safe to use on plastic cutting boards?

- Yes, packaging tape is safe to use on plastic cutting boards. Packaging tape is designed to adhere to a variety of surfaces, including plastic, without causing any harm or damage. It is commonly used for sealing packages and boxes, and does not contain any harmful chemicals or substances that would pose a risk to the plastic cutting board or the food being prepared on it. However, it is important to note that using packaging tape on a cutting board is not a recommended practice for food safety reasons. It is best to use food-grade materials, such as food-safe adhesive tape or rubber bands, to secure plastic cutting boards to prevent any potential contamination.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. It provides a secure and effective way to seal the packaging, ensuring that the contents remain protected during transportation or storage.

- Q: Does packaging tape come in different patterns or designs?

- Yes, packaging tape does come in different patterns and designs.

Send your message to us

IPG Masking Tape Temperature Resistance 80 Colour Red World Top 500 Enterprise

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords