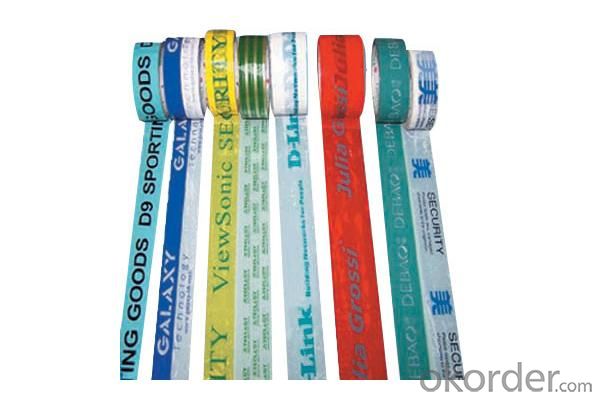

Green Packaging Tape - OPP Tape Customized Printed for Packing and Sealing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 roll

- Supply Capability:

- 456766 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: OPP film

Adhesive Side:Single Sided

Adhesive: Water Based Acrylic

Use: Carton Sealing and Packing,Light Duty Packing,Bounding,Holding and other office and household use

Design Printing: Offer Printing

Place of Origin: China (Mainland)

Model Number: Red opp packing tape Strong adhesive

Color: Clear, Tan, Yellowish, Brown, Yellow, White, Black, Blue, Green, Red etc.

Standard Size: 48mm x 66m, 50mm x 50m, 1.28m x 4000m, etc

Applications:

OPP Tape Customized Printed is economical for general carton sealing

Auto-packing machine

Gift Wrapping & Decoration

Bundling &Strapping

Meet all kinds of transportation convenientl

Production Description:

OPP Tape Customized Printed is made from OPP(Oriented polypropylene) film coated with acrylic adhesive.It is widely used for automatic carton Adhesive Packing Tape packing machines troughout various industries.

- Q: Is packaging tape easy to tear by hand?

- Yes, packaging tape is generally easy to tear by hand. Most packaging tapes are designed with a serrated edge or perforation, making it easy to tear off a desired length without the need for scissors or any other tools. This feature allows for quick and convenient packaging and sealing of boxes or packages without any hassle. However, it is important to note that the ease of tearing may vary depending on the brand and quality of the packaging tape.

- Q: What are the benefits of using high-visibility packaging tape?

- High-visibility packaging tape offers numerous benefits for various applications. Firstly, its bright color, often fluorescent or neon, significantly enhances visibility, making it easy to locate and identify packages. This is particularly advantageous in busy shipping and receiving areas where numerous packages are handled simultaneously, ensuring efficient and accurate sorting. Additionally, high-visibility packaging tape increases safety in the workplace. Its bright color acts as a visual warning, alerting employees and customers to potential hazards, such as fragile or dangerous contents. This reduces the risk of mishandling or accidents, preventing damage to products and potential injuries to individuals. Furthermore, the use of high-visibility tape improves inventory management. With its distinctive color, it becomes simpler to differentiate between different packages, aiding in organization and tracking. This is particularly beneficial in warehouses or storage facilities where large quantities of goods are stored, enabling efficient stock management and easy identification during inventory checks. Another advantage of high-visibility packaging tape is its ability to deter theft or tampering. The vibrant color draws attention to any unauthorized attempts to open or tamper with the package, discouraging potential thieves or unauthorized persons from interfering with the contents. This enhances security and helps protect valuable or sensitive items during transit. Moreover, high-visibility packaging tape is often designed with strong adhesive properties, ensuring secure sealing of packages. This prevents accidental openings during transportation, safeguarding the contents from damage, loss, or contamination. The reliable sealing also helps maintain the integrity of the packaging, ensuring that it withstands various environmental conditions, such as humidity or temperature fluctuations. In conclusion, the benefits of using high-visibility packaging tape include improved visibility, enhanced safety, efficient inventory management, theft deterrence, and secure sealing. These advantages make it an excellent choice for businesses and individuals involved in shipping, receiving, and storing packages, providing peace of mind and facilitating smooth operations.

- Q: Does packaging tape have any specific safety precautions?

- It is important to note that packaging tape requires specific safety precautions to be followed. Firstly, handling the tape with care and avoiding sharp or sudden movements is crucial to prevent any potential injuries. While the tape itself is generally safe, mishandling it can lead to cuts or punctures. In addition, using the appropriate type of packaging tape for the intended purpose is essential. Different materials and adhesives are designed for specific applications, such as sealing boxes or securing heavy items. Using the wrong kind of tape may result in inadequate sealing or potential hazards. Moreover, storing packaging tape in a safe place away from extreme temperatures, moisture, or direct sunlight is vital. These factors can impact the adhesive properties of the tape and compromise its effectiveness. Lastly, wearing protective gloves, especially when handling sharp or heavy objects, is advisable when using packaging tape. This provides an extra layer of safety and helps prevent potential injuries. By adhering to these safety precautions, users can effectively utilize packaging tape while minimizing the risk of accidents or harm.

- Q: Can packaging tape be used for sealing packages with electronics or electrical components?

- Yes, packaging tape can be used for sealing packages with electronics or electrical components. However, it is important to consider the specific requirements of the components being sealed, such as static electricity protection or insulation. In some cases, specialized tapes or additional protective measures may be necessary to ensure the safety and integrity of the electronics during transportation or storage.

- Q: Can packaging tape be used for sealing wooden crates or pallets?

- Yes, packaging tape can be used for sealing wooden crates or pallets. It provides a secure adhesion and helps to keep the contents of the crates or pallets protected during transportation or storage.

- Q: Can packaging tape be used for sealing packages with sharp or pointed objects?

- Yes, packaging tape can be used for sealing packages with sharp or pointed objects. However, it is recommended to take additional precautions such as cushioning the sharp or pointed objects with protective material or placing them in a sturdy box to prevent the tape from getting damaged or punctured during transit.

- Q: Is packaging tape safe to use on plastic cutting mats?

- Before using packaging tape on plastic cutting mats, it is important to take a few factors into consideration. Firstly, make sure that the cutting mat is made of a durable and food-safe material. Some lower quality mats may get scratched or torn when tape is applied, so it is advisable to check the manufacturer's recommendations. Secondly, think about why you want to use packaging tape on the cutting mat. If it is for temporary storage or transportation, packaging tape can provide a secure seal. However, if the tape will come into direct contact with food or be used during food preparation, it is best to avoid using packaging tape. The adhesive residue from the tape could transfer onto the food or contaminate the cutting surface, which could be a health risk. In such cases, it is better to use food-grade or specialized tape that is specifically designed for cutting mats or food preparation surfaces. In conclusion, although packaging tape can be safe to use on plastic cutting mats, it is crucial to consider the quality of the mat, the purpose of using the tape, and potential food safety concerns. Always prioritize the safety and hygiene of your food preparation surfaces by choosing the appropriate tape.

- Q: Does packaging tape come in different adhesion levels for various surfaces?

- Yes, packaging tape does come in different adhesion levels for various surfaces. There are packaging tapes available with different adhesive strengths to adhere to different surfaces such as cardboard, plastic, or metal. This allows for better packaging and ensures that the tape securely sticks to the desired surface.

- Q: Can packaging tape be used for sealing plastic toys?

- Yes, packaging tape can be used for sealing plastic toys. It provides a strong adhesive bond and helps keep the toy's packaging secure.

- Q: Is packaging tape waterproof?

- Yes, packaging tape is typically waterproof. It is designed to provide a secure seal and protect packages from moisture and other external factors during transit or storage.

Send your message to us

Green Packaging Tape - OPP Tape Customized Printed for Packing and Sealing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 roll

- Supply Capability:

- 456766 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords