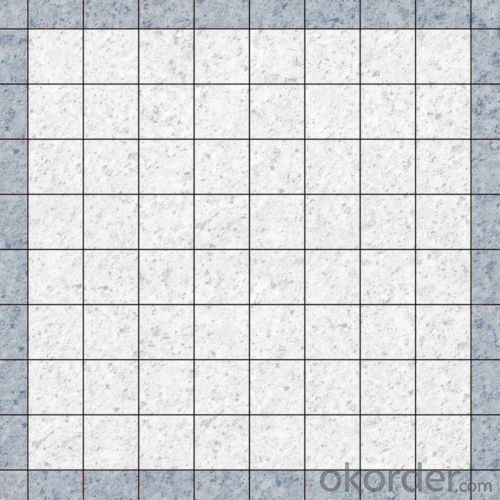

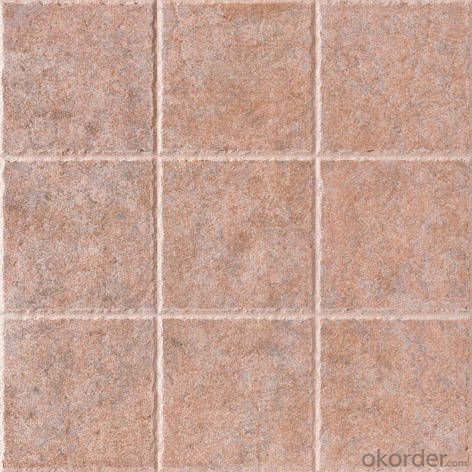

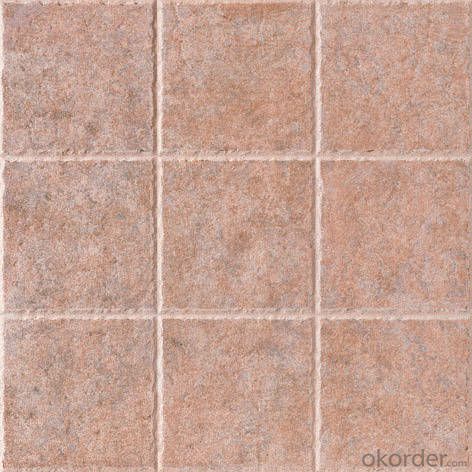

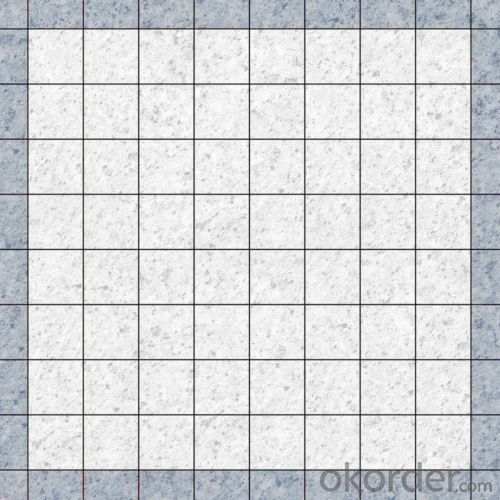

Acid Resistant Sintered Paving Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.Acid-resistant for paving brick2.Excellent quality

3.Excelletn abrasion resistance

4.High water-permeable quality

Specification and size

material: pottery clay or clay

color: red,brown,chestnut,khaka,and so on

size is availabe arrording to customer's requirements.

Feature

1.excellent quality and abrasion resistance

2.acid-resistance.

3.using long life

4.easy to maintain

5.non-polluting

pysical and chemical index

| Item | requirement |

| ≤positive skin and strick the maximum projection size of defect | 10.0mm |

| ≤edge off missing the maximum angle of projection size | 15.0mm |

| ≤non-through crack length size of the largest projection | 10.0mm |

| through the cracks | not allowed |

| stratified | not allowed |

brick size tolerance of physical and chemical

Item | requirements |

length,width | ±2.0 |

thickness | ±2.0 |

thickness difference | ±2.0 |

vertical | ≤2.0 |

flatness | ≤2.0 |

straight angle | ≤2.0 |

- Q: How to clean the acid brick surface dirt?

- Daily cleaning of bricks can be done with detergent, soap and other cleaning.

- Q: What are the standard specifications for acid resisting bricks?

- Because of the different acid and alkali environment, the acid resisting ceramic tile has different requirements on the degree of acid and alkali, so it is necessary to make the price reasonable at the time of construction,

- Q: Acid proof brick, acid resistant porcelain in the paste process with no seam

- As the base layer, bonding layer and acid brick itself thermal expansion, cold shrinkage coefficient is very different, in 1-2 years of hot and cold tension failure, too dense paving easily lead to acid brick swelling, fracture and other issues

- Q: The difference between acid and heat resistant lightweight castables and acid resisting bricks

- The difference between acid and heat resistant lightweight castables and acid resisting bricks:Acid resistant brick is a ceramic product, which is fired by high temperature. The casting material is poured by chemical reaction after the material is diluted.

- Q: Is it necessary to use sulphate resisting cement in alkaline areas?

- The sulfate resisting silica cement is divided into two categories: medium sulfate resistant Portland cement and high sulfate resistant Portland cement. A suitable cementitious material with resistance to moderate concentration of sulfate ion is prepared by adding proper amount of gypsum in the proper proportion of Portland cement clinker, which is called medium sulfate resisting portland cement. Middle sulfur resistant cement. Code P & MSR. A cementitious material with high resistance to sulfate ion corrosion is prepared by adding proper amount of gypsum into the clinker of proper proportion of Portland cement clinker, which is called high sulfate silica cement. High sulfur resistant cement.

- Q: Which acid proof tile factory is reliable in quality?

- We all know that the main component of acid resistant ceramic which is silica, liangdun acid resistant ceramic material is used by Shanxi local quartz stone, containing a large number of silicon content, acid resistant tiles can thus produced corrosion.

- Q: What is acidproof brick?

- The main component of acid resistant brick is silica, and Hao Ran acid resistant bricks are made of imported raw materials and imported color materials by high temperature firing.

- Q: Construction method of acid proof brick

- Construction preparationFamiliar with drawings, specifications, technical disclosure, do a good job of the handover process.Material preparation: the anti-corrosion materials used in this project are stored in the appropriate warehouse (site), and the incoming materials are tested to comply with the requirements of the HGJ229-91 specification.Equipment preparation: cutting machine, mixer, grinder, trolley, cement plate, rope, hose, shovel, wipe, steel scraper, rubber hammer, steel wire brush, brush, putty knife, the level of scale, by foot, rope, wire, small pendant, Jue measuring cup, scales, tarps, ventilation and lighting equipment.

- Q: The difference between polished tiles and glazed tiles?

- Just because of the surface layer, so the pattern will slowly fade, it looks very old, but the brick does not have this problem, the brick on the market, some does not completely block brick has a pattern, just by the superposition technique, will have almost half the above pattern.

- Q: Cleaning metal surface rust stain, is it better to weld sulphuric acid or nitric acid?

- The principle of treating oxide skin with salt bath method has been introduced in the second article. When the oxide in the oxide scale of the metal surface has chemical reaction, because the expansion coefficient of the oxide layer and the metal matrix is different, the rust scale and the metal matrix can separate and fall off.

Send your message to us

Acid Resistant Sintered Paving Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords