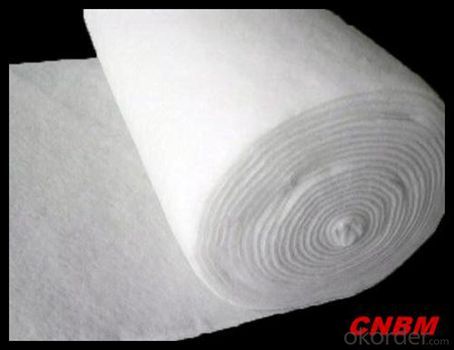

Acf Geotextile 100% PP Spunbond Nonwoven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

About K&D Non Woven Fabric:

1) Composition: 100% polypropylene

2) Weight: 10 - 300gsm

3) Width: maximum 2.4m wide (can be splited)

4) Various colors available

5) Characteristics: environmentally-friendly, good tensile strength, soft, lightweight,

non-toxic, water-resistant, air permeable

6) Usage:

a).daily use: making shopping bags, suit cover, surgical cover, cloth interlining, table cloth, bed sheet etc.

b). In agriculture: to protect the crop from pest harm, allows water, air and fertilizer to penetrate and reduces moisture evaporation.

c). in industry: to wrap to drainpipe etc.

7) Auxiliary treatment: UV protection, anti-virus, fire-retardant, antistatic, hydrophilic

8) Customers' specifications available

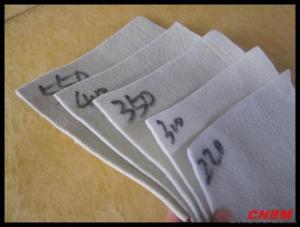

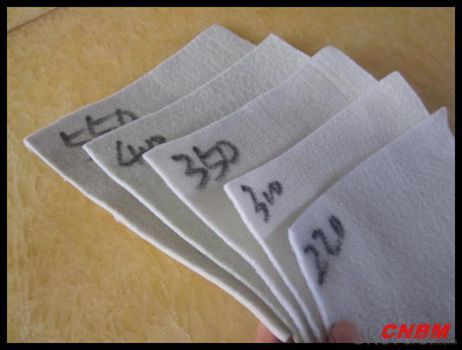

Polyester Nonwoven Geotextile Specification:

No | Project | Index | ||||||

1 | Breakage Strength KN/m≥(MD) | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

2 | Breakage Strength KN/m≥(CD) | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

3 | Elongation Rate (MD,CD) ≤ | 28 | ||||||

4 | Trapezoidal Tearing Strength | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

5 | Burst Strength KN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

6 | Vertical Permeability Coefficient cm/s | 10-1~10-3 | ||||||

7 | Sieve size(O95) mm | 0.08~0.5 | ||||||

8 | Unit weight g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

9 | Thickness mm | 0.40 | 0.48 | 0.60 | 0.70 | 0.80 | 1.00 | 1.25 |

10 | Variation % | ±10 | ||||||

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the applications of geotextiles in civil engineering?

- Geotextiles have various applications in civil engineering, including soil stabilization, erosion control, filtration, drainage, and reinforcement. They are commonly used in road construction, retaining walls, embankments, and landfills to improve the performance and durability of these structures. Geotextiles offer benefits such as increased load-bearing capacity, enhanced drainage, and reduced soil erosion, making them essential components in many civil engineering projects.

- Q: What are the cost considerations for geotextiles?

- The cost considerations for geotextiles include the material cost, installation cost, maintenance cost, and the overall lifespan of the geotextile. Additionally, factors such as the type and quality of the geotextile, the size of the project, and any specific requirements or regulations can also impact the cost. It is important to carefully evaluate these considerations to determine the most cost-effective solution for a geotextile application.

- Q: How do geotextiles help with filtration in geosynthetic clay liners?

- Geotextiles help with filtration in geosynthetic clay liners by serving as a barrier between the clay liner and the surrounding soil. They prevent the migration of fine particles from the soil into the clay liner, ensuring efficient filtration and preventing clogging of the clay liner.

- Q: Are geotextiles suitable for use in geogrid reinforced slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced slopes. Geotextiles are often used as a separation and filtration layer in geogrid reinforced slopes to prevent the mixing of soil layers and ensure proper drainage, stability, and reinforcement. They help in distributing loads and reducing soil erosion, making them a valuable component in geogrid reinforced slopes.

- Q: Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are designed to provide strength, stability, and filtration in various applications, including landfill construction. They can be used as a reinforcement layer in landfill liners or caps to enhance the stability and prevent erosion of the waste containment system.

- Q: Geotextile detection frequency

- GB / T-2009 / ISO9862: 2005 does not specify the frequency, but according to the general provisions of the construction material is required to declare the material inspection, the specific number of consultation with the testing agency, the general geotextile detection: thickness (sample length 1m, (Sample length 1m, the number of samples 10 10 × 10), tensile properties (wide stretch, trapezoidal tear (sample length 2m, the number of samples vertical and horizontal to the five blocks ))

- Q: What are the advantages of using geotextiles?

- Geotextiles offer several advantages such as soil stabilization, erosion control, filtration, and drainage, which can enhance the overall performance and longevity of civil engineering projects. They provide a cost-effective solution by reducing the need for extensive excavation, improving load-bearing capacity, and minimizing long-term maintenance requirements. Additionally, geotextiles are environmentally friendly, allowing water and air circulation while preventing soil erosion, thereby promoting sustainable development and conservation of natural resources.

- Q: What are the different geotextile installation guidelines?

- There are several different geotextile installation guidelines that vary depending on the specific project and goals. Some common guidelines include ensuring proper site preparation, including clearing and grading the area, as well as removing any debris or vegetation. It is important to properly measure and cut the geotextile to fit the designated area, allowing for overlap and securing the edges. Additionally, proper anchoring methods should be used to prevent movement or displacement of the geotextile. Finally, regular inspection and maintenance should be conducted to ensure the geotextile is functioning as intended.

- Q: 250 grams of geotextile how much money a square

- 250g geotextile market price of 2.3 yuan a square meter

- Q: What causes the geotextile aging phenomenon

- Gundam has the characteristics of the product we are all obvious, both in the highway, dams, railways and many other occasions have a very strong product features, and the performance is very outstanding, geotextile is an irreplaceable geotechnical material. Although the geotextile has unparalleled advantages, but the product is not perfect that any product has more or less problems or less, geotextile is the same, its aging problem has been with us, then in the end what causes Geotextile aging? Geotextile aging problem refers to the geotextile in the sun by the smell, temperature changes, biological erosion, chemical corrosion, moisture and other external factors, so that the geotextile strength and performance gradually weakened, loss of seepage effect. UV radiation intensity changes with the intensity of solar radiation, geotextile aging speed with the intensity of UV radiation and speed. Synthetic polymer polymer is concerned, the sun radiation is the main factor in the degradation of polymer degradation. UV radiation in the sun is the most important factor in the aging of the fabric. The ultraviolet radiation causes the polymer to produce a photooxidative decomposition reaction, especially ultraviolet light at a wavelength of 290 to 400 mPm, which has a significant decomposition effect on the polymer , Because the geotextile in the range of ultraviolet light energy is higher than the polymer chemical steamed broken the required energy, so the polymer material aging is very obvious.

Send your message to us

Acf Geotextile 100% PP Spunbond Nonwoven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords