Aca Aluminum Coil Anodizing Corp Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

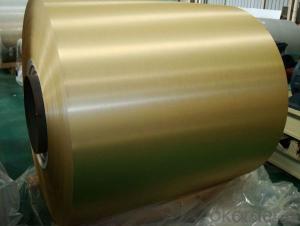

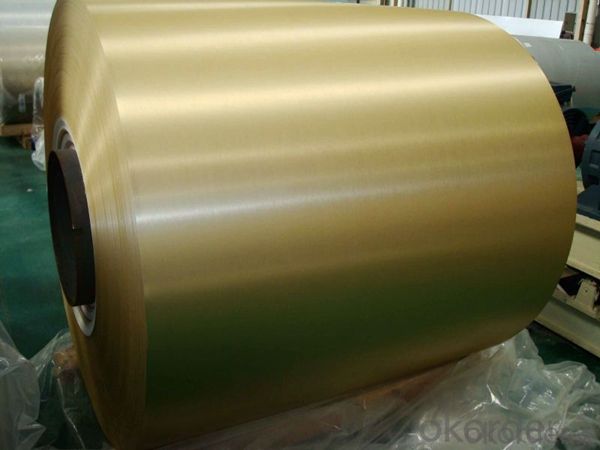

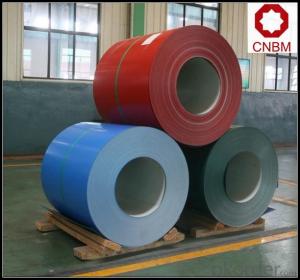

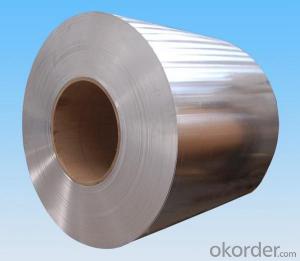

5. Image of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

6. Package and shipping of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for the distinctions between two types of metal coils: aluminum and iron.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has good electrical conductivity, making it ideal for applications like electrical wiring and packaging. Iron coil, on the other hand, is heavier, stronger, and more magnetic, commonly used in construction and manufacturing for reinforcement and structural support. Additionally, iron is more prone to rust compared to aluminum, which is more resistant to corrosion. The cost and availability of these materials also vary, with aluminum being more abundant and less expensive than iron.</p>

- Q: What are the different grades of aluminum used in coil production?

- The different grades of aluminum used in coil production typically include 1100, 3003, and 5052. These grades vary in terms of their composition and properties, allowing for specific applications and requirements in various industries.

- Q: How do aluminum coils contribute to reduced maintenance costs?

- Aluminum coils contribute to reduced maintenance costs due to their corrosion-resistant nature. Unlike other metals, aluminum does not rust or corrode easily, which means that the coils require less maintenance and replacement over time. This leads to cost savings as there is less frequent need for repairs, coatings, or replacements, resulting in reduced maintenance expenses.

- Q: What are the tensile strength properties of aluminum coils?

- The tensile strength properties of aluminum coils are known to be quite high. Aluminum, as a material, possesses excellent strength-to-weight ratio, which makes it suitable for various applications that require strength coupled with lightweight properties. The specific tensile strength of aluminum coils can vary depending on the alloy and temper used. Generally, aluminum coils have a tensile strength ranging from 110-310 MPa (megapascals), or approximately 16,000-45,000 psi (pounds per square inch). These values indicate the maximum amount of tensile stress that the aluminum coil can withstand before it breaks or deforms permanently. It is important to note that the tensile strength can be further enhanced by heat treatment processes such as cold rolling or annealing. Overall, aluminum coils are recognized for their impressive tensile strength properties, which contribute to their wide usage in industries like aerospace, automotive, construction, and manufacturing.

- Q: Can aluminum coils be used in heat exchanger fins?

- Indeed, heat exchanger fins can utilize aluminum coils. Aluminum is widely preferred for heat exchangers owing to its remarkable thermal conductivity, lightweight properties, and resistance to corrosion. By incorporating aluminum coils into heat exchanger fins, the transfer of heat between two fluids becomes highly efficient, making it an ideal material for this specific purpose. Moreover, aluminum coils can be effortlessly shaped into different fin configurations, which allows for design flexibility and maximizes the surface area for heat transfer. All in all, aluminum coils are commonly employed in heat exchanger fins to boost heat transfer efficiency and enhance the overall performance of the heat exchanger system.

- Q: Can aluminum coils be used in heat exchanger fins?

- Yes, aluminum coils can be used in heat exchanger fins. Aluminum is a common material choice for heat exchangers due to its excellent thermal conductivity and corrosion resistance. Aluminum coils can efficiently transfer heat and withstand high temperatures, making them suitable for use in heat exchanger fins.

- Q: I would like to know because I'm getting a sword with an aluminum sheathe.

- No, it is a very soft metal. However for a sheath it will likely be fine, unless you intend on practicing using the sheath for blocking as some Samurai used it for.

- Q: Are aluminum coils compatible with other materials?

- Yes, aluminum coils are compatible with other materials. Aluminum is a versatile and widely used material that can be easily integrated with various other materials in different applications. For example, aluminum coils can be used in conjunction with copper tubing in air conditioning and refrigeration systems to enhance heat transfer efficiency. Additionally, aluminum coils can be coated or laminated with other materials such as polymers or paints to provide additional protection against corrosion, improve aesthetics, or enhance specific performance characteristics. Therefore, aluminum coils offer compatibility with a range of materials, making them suitable for diverse applications in industries such as construction, automotive, aerospace, and more.

- Q: need to know the procedure for removal of aluminum windows with brick trim

- We contemplated this issue ourselves... The best suggestion we got from a friend who was a window installer was to measure the existing window carefully and order a custom replacement Block frame window. To remove the existing window (once you have verified that the window you recieved is actually the size you ordered--don't skip this step!) Remove the vent and sash from the aluminum window -- this may mean some glass breakage so be careful and use gloves. Use a sawzall or reciprocating saw to cut along the outside edge of the window where the nailing fin should be attaching it to the framing beneath the block or brick. If you use the correct blade, you should have no trouble cutting through the aluminum. Make sure to wear saftey glasses as you DO NOT want aluminum shavings in your eyes! Once your opening is clear, level and plumb the new window using shims and screw directly through the inside of the window frame into the frame of the opening. You will need to get covers for the screw heads so that they don't show once your installation is complete. Good Luck!

- Q: ... of aluminum atoms?(mole = 6.022x10^23)

- My lady I nevertheless use it to cook dinner my hams and turkeys and to save nutrition interior the frig, yet its growing to be a dinosaur and its on its final leg and there is unquestionably one of those super form of different issues now we are able to apply yet interior the previous years it had its use yet technology and Tech. has come and made it out of date. yet nevertheless i like to apply it on ocassions

Send your message to us

Aca Aluminum Coil Anodizing Corp Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords