Abrasive screen—A400#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

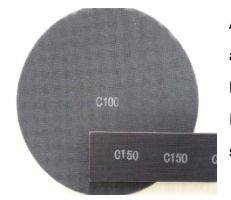

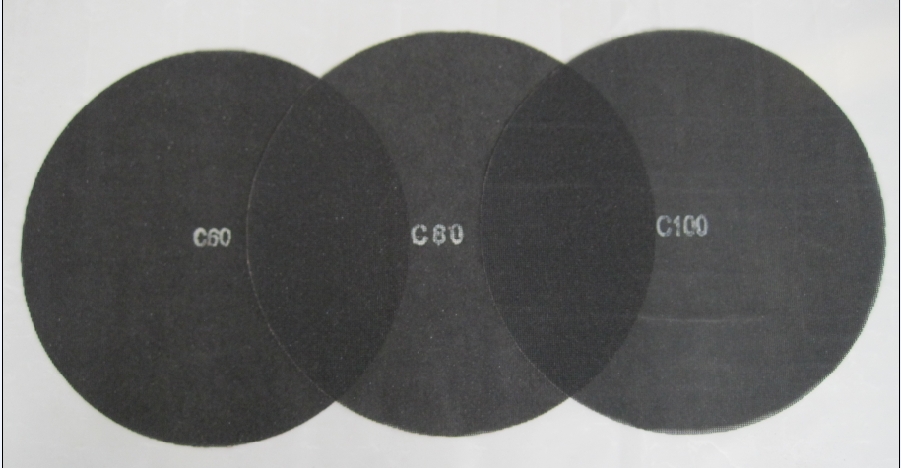

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: How to install the bathroom bracket

- With a general drill, with a glass-specific drill, to ensure that will not drill tiles!

- Q: Can steel tube couplers be used for both single and multi-tier scaffolding structures?

- Yes, steel tube couplers can be used for both single and multi-tier scaffolding structures. These couplers provide a secure and reliable connection between the steel tubes, allowing for the construction of scaffolding structures of various heights and configurations.

- Q: Did the pageantry of pain at the scaffold actually deter people of crimes during the 18th century?

- Probably not. Pick-pockets were said to work in the crowds round the gallows, so they were clearly not deterred. Too many crimes carried the death penalty, and the chances of being caught and convicted were not high. Among criminals hanging was probably seen as a normal risk of the trade. Jonathan Wild, the 'Thief-taker General', married a widow, whose husband had been hanged (with the help, it was rumoured, of Wild) - the public hangman was a guest and danced at the wedding, and Wild himself was hanged later.

- Q: How do geomembranes contribute to groundwater remediation projects?

- Geomembranes contribute to groundwater remediation projects by serving as a barrier that prevents the contamination of groundwater. They are used as liners or covers in containment systems to isolate and contain contaminants, such as hazardous chemicals or pollutants, preventing them from leaching into the groundwater. Additionally, geomembranes help to control the flow of groundwater, allowing for the implementation of various remediation techniques, such as pump-and-treat systems or in situ treatment methods. Overall, geomembranes play a crucial role in protecting and restoring groundwater quality in remediation projects.

- Q: My house loft skylight is not open, only a large piece of glass. Heavy rain in the past few years is always leaking. I would like to use their own glass in the roof of the house can be squeezed on it? The Because it is not convenient to the roof. Glass glue can stick lime wall, because the glass is another contact surface is lime wall. Do not know the glass glue effective ineffective. More

- The basic can not repair, glue no use, more information, better advice, free to provide concrete waterproof leaking water repair technical advice, from today's repair, tomorrow leak, year-old repair,

- Q: Are geotextiles suitable for use in erosion control mats for revegetation?

- Yes, geotextiles are suitable for use in erosion control mats for revegetation. Geotextiles are designed to stabilize soil and prevent erosion by providing a barrier against water and wind. They also promote vegetation growth by allowing water and nutrients to penetrate the soil while protecting the roots from erosion. Overall, geotextiles can be an effective solution for erosion control in revegetation projects.

- Q: How do blockboards be classified according to board core structure?

- Three-tier blockboard: in the core of the two large surface of the paste a layer of veneer made of blockboard.

- Q: Choice of solid wood flooring to pay attention to what, after the completion of the road to pay attention to how to maintain

- The rainy season, the keel can also increase a gross floor or linoleum, avoid damp floor deformation, wood floors Juegan comfortable, but the pavement must be carefully, and to pay attention to maintenance.

- Q: What is the difference between aluminum windows and wooden-aluminum composite windows?

- Aluminum aluminum composite doors and windows of the aluminum alloy wall thickness of 2.2-2.4mm, and aluminum clad aluminum alloy wall thickness is usually about 1mm. Aluminum clad wood is only on the form of imitation of aluminum and wood, into the window strength is only relying on solid wood, and aluminum composite window into the window strength can reach 1 +1> 2. The so-called "1 + 1> 2" that is the strength of the window is greater than the sum of the strength of aluminum and solid wood. Popular terms, aluminum bags of wooden doors and windows are wood and more aluminum, and wooden bags of aluminum doors and windows are less wood and more! The main force structure of the aluminum clad wood is pure solid wood, while the inside of the wooden bag aluminum is a layer of wood, the main force structure for the broken bridge aluminum alloy. Most of the aluminum doors and windows are made of red oak wood or larch pine as the main structural material, through the processing center and other intelligent mechanical machine tools, doors and windows become the most important part of the aluminum is covered in the wood outside to withstand the wind and sun , To avoid wood decay aging. Wooden aluminum and aluminum clad windows in the installation of the appearance is very similar to the interior of the solid wood for the bridge off the aluminum alloy material, through a special process in the window side of a layer of high quality pure wood, thus forming wooden bag aluminum windows, such a perfect structure To retain the aesthetic characteristics of wooden windows, while increasing the rigidity of wood windows, weather resistance, wind pressure and other characteristics.

Send your message to us

Abrasive screen—A400#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords