Abrasive screen—A1000#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

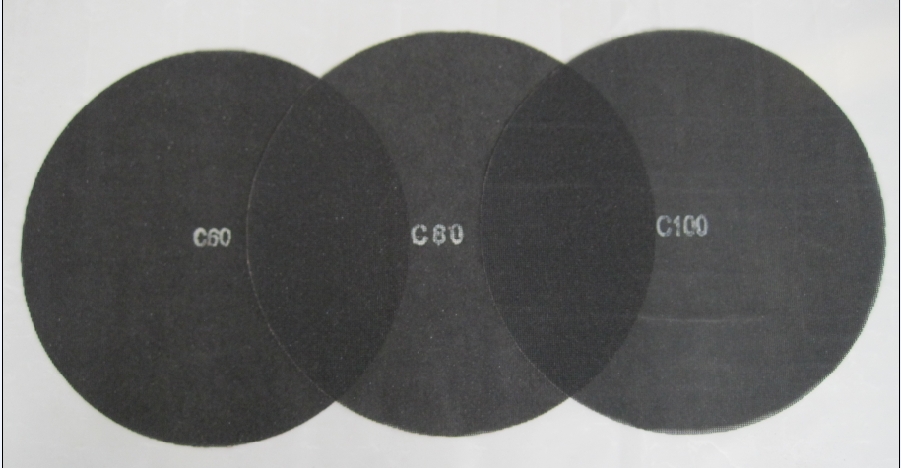

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: Aluminum alloy door and window frame and hole wall gap for how much, in the specification can be found

- Look at the surface material, the general coating is 5mm enough, if it is stone, you need 20-30 or even larger.

- Q: What are the disadvantages of using steel formwork?

- One disadvantage of using steel formwork is its relatively high cost compared to other types of formwork materials. Additionally, steel formwork is heavy and requires special equipment for handling and installation, making it less convenient to transport and set up on construction sites. Moreover, steel formwork needs to be properly maintained to prevent rusting and corrosion, which adds to the overall maintenance cost. Lastly, steel formwork may not be suitable for complex and intricate architectural designs that require flexible formwork systems.

- Q: What can be used to mop wax floors in-between waxes? My employees and I are having a hard time finding a cleaner that won't ruin the surface. For now, we are using just hot water and a mop but the water always leaves marks and doesn't seem to really do any. It just seems to make it dirtier. Any suggestions?

- get a bucket of clorox and a mop.... OOOORRR u can hire a proffessional to do ur job!!!

- Q: How does steel formwork contribute to the overall aesthetics of a structure?

- Steel formwork is a versatile and durable construction material that plays a crucial role in shaping the overall aesthetics of a structure. Its contribution to the aesthetics of a building can be seen in several ways. Firstly, steel formwork allows for precise and intricate designs to be achieved. The flexibility and strength of steel enable architects and designers to create complex shapes and unique forms that would be challenging or impossible to achieve with other construction materials. This ability to create innovative and eye-catching designs enhances the visual appeal of a structure, making it stand out in its surroundings. Additionally, steel formwork provides a smooth and seamless finish to the concrete surface. The precise manufacturing of steel panels ensures that there are no gaps or imperfections, resulting in a flawless and uniform appearance. This smooth finish enhances the overall aesthetics of the structure, giving it a sleek and modern look. Furthermore, steel formwork allows for larger uninterrupted spans and open spaces to be created. The strength of steel enables the construction of thinner and lighter elements, such as slabs and beams, without compromising on structural integrity. This characteristic of steel formwork gives architects the freedom to design structures with expansive windows, open floor plans, and generous amounts of natural light. These features not only improve the functionality of a building but also contribute to its aesthetic appeal by creating a sense of spaciousness and connection with the surrounding environment. Moreover, steel formwork offers the advantage of being reusable, which can significantly reduce construction waste and environmental impact. This sustainability aspect of steel contributes to the overall aesthetics of a structure by aligning it with modern principles of eco-friendly construction. The use of steel formwork demonstrates a commitment to sustainable design practices, which can enhance the perceived value and attractiveness of a building to potential occupants and investors. In conclusion, steel formwork contributes to the overall aesthetics of a structure through its ability to facilitate intricate designs, provide a smooth and seamless finish, create larger open spaces, and support sustainable construction practices. Its versatility and durability make it an ideal choice for architects and designers looking to achieve visually appealing and distinctive structures.

- Q: How to calculate the general loss of the installation of wood flooring?

- Calculated from 2% to 3%. I'm doing the budget.

- Q: Composite floor and solid wood floor difference in that?

- Composite flooring is generally composed of four layers of composite materials: the bottom layer, the substrate layer, decorative layer and wear-resistant layer. Wherein the number of revolutions of the wear layer determines the life of the composite floor. Solid wood flooring is a natural wood by drying, processing after the formation of the ground decoration material 窢 chu chu let's see the color of the material. It presents a natural wood texture and color patterns, giving a natural, soft, rich affinity texture, at the same time because of its cool and cool summer, feel good to make it a bedroom, living room, study and other ground decoration of the ideal material.

- Q: Are geogrids suitable for stabilizing soft soils?

- Yes, geogrids are suitable for stabilizing soft soils. Geogrids are commonly used in civil engineering projects to reinforce and stabilize soft soils by distributing the load more evenly and increasing their bearing capacity. They provide tensile strength to the soil, preventing excessive deformation and potential failure. Additionally, geogrids can improve the overall stability of the soil, reducing the risk of settlement or differential settlement.

- Q: How do geomembranes contribute to erosion control in oil and gas pipeline construction?

- Geomembranes contribute to erosion control in oil and gas pipeline construction by providing a protective barrier against water and soil erosion. They are installed as liners or covers to prevent soil erosion and protect the pipeline from the effects of weathering and water flow. This helps to maintain the stability of the pipeline and minimize the risk of leaks or damage caused by erosion.

- Q: Can steel formwork be used for both vertical and horizontal structures?

- Yes, steel formwork can be used for both vertical and horizontal structures. Steel formwork is a versatile and durable construction material that can be molded and shaped to meet the requirements of various structural elements. It can be used for constructing walls, columns, beams, slabs, and other structural elements in both vertical and horizontal orientations. The strength and rigidity of steel make it suitable for withstanding the pressure exerted by concrete during the casting process, ensuring that the formwork maintains its shape and stability. Additionally, steel formwork is reusable and can be easily dismantled and reassembled, making it a cost-effective and efficient choice for construction projects involving both vertical and horizontal structures.

- Q: The toilet has a static flush, I would like to ask "static" is what kind of flushing

- In fact, the use of the siphon flush, first talk about the jet siphon flush: the flush is divided into two, all the way directly to the toilet wall, the other way from the independent pipeline through the pool below the hole directly , In order to increase the intensity of flushing, and produce siphon effect, the dirt discharged from the toilet

Send your message to us

Abrasive screen—A1000#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords