Abrasive screen—A40#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

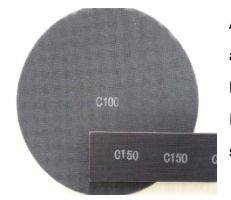

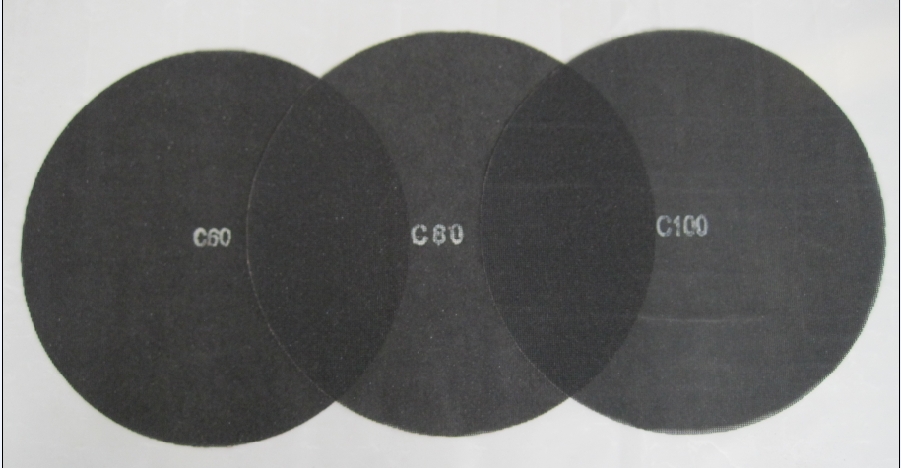

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: My curtains were black witch I hate now! Besides any shade of purple, what other colors would match my grape purple walls?MY bedspread has some stains, no matter how many times I wash it it wont come out! I need some new bedspreads, but what design/color? Currently my bedspread is blue purple and green, I dont really like it anymore. Would something light brown would look nice? Whats your opinion? Thanks!

- I always thought light chocolate brown matched well, but wont suit everybody.. I just saw the question, and thought I would give you my opinion. At the end of the day the choice of colour is yours, but on paper brown and purple match.

- Q: Duplex structure of the house, the lower part of the compartment hanging gypsum board ceiling problem

- Only in the four weeks before the first set a good level, I-beam above the need to put things, such as you said the cement board, etc., first placed well, and then follow the normal ceiling to do. Surrounded by the wall of the eye, the middle can be fixed with wood on the I-beam, and then add the wood made of gypsum board keel (gypsum board fixed on the woods). If the height is limited, you can close to the lowest level of I-beam position to do; if you need to drop a little, you can also level down.

- Q: Will the mechanical material mechanics and civil material mechanics different?

- The difference is definitely big, the mold does not change. But the mechanical and electrical materials and civil nature is not the same

- Q: Can the composite floor be installed,

- Technical requirements are not high, you can do it yourself, pay attention to the general installed from the door, inside the corner of the mouth.

- Q: Circuit board plate classification, distinction between advantages and disadvantages

- The main criteria for substrate materials: National standards: China's national standards for substrate materials GB / T4721-47221992 and GB4723-4725-1992, China Taiwan's copper clad plate standard for the CNS standard, is based on the Japanese JIs standard modeled, published in 1983 The International standards: Japan's JIS standards, the United States ASTM, NEMA, MIL, IPc, ANSI, UL standards, the British Bs standards, Germany DIN, VDE standards, France's NFC, UTE standards, Canada CSA standards, Australia's AS Standards, the former Soviet Union's FOCT standards, international IEC standards.

- Q: And what is it sticking to the wall? Thank you, wait an hour online

- If a small pot on the tens of dollars can be, there are the following iron stent to sell, need to punch on the wall to install the bracket, a small pot on top. The edge of the last white glass glue on the gap. If you buy a frame with a washbasin, hundreds of dollars can be bought, there are directly on the ground, but also with screws fixed on the wall

- Q: 3Dmax in the circular ceiling, gypsum line how to model?

- Gypsum line to do a good look at the shape of a pull out of the ah

- Q: I bought a vanity made by American Standard. It has a wood-like paper applied on it, with some material (glaze or varnish etc). Can I use such paper material on the kitchen cabinets? Does it last? Where do they sell wood paper? The stain seems to be fully absorbed by the wood so it is not coming off. I dont like to paint the cabinets. However, this wood paper gives some shade/grain-like look to the bathroom vanity. I want the kitchen cabinets to look similar.

- if the sides of the cabinets are melamine then no you cannot buy that paper and apply it yourself. it is done in the manufacturing process and applied to cheaper substrates to give the look of real wood sorry, more affordable substrates is what I meant it can be bought as full sheet like plywood is available but may be too thick to apply to the side of a cabinet without the raw edges being exposed I suppose you could look for a wood grain wallpaper, someone somewhere probably makes it, but I am not sure if that would hold up well on cabinets especially when steam is coming up from a pot on the stove

- Q: Less than three months of pregnancy are all wood furniture processing plants, as well as metal doors and windows processing plant will affect the tire

- We know that the new furniture to buy all contain toxic and harmful gases, there are some ventilation for several months, indoor air pollutants are still exceeded, mainly formaldehyde.

- Q: What are the common failure modes of steel tube couplers in scaffolding?

- The common failure modes of steel tube couplers in scaffolding include improper installation, overloading, corrosion, fatigue, and material defects.

Send your message to us

Abrasive screen—A40#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords