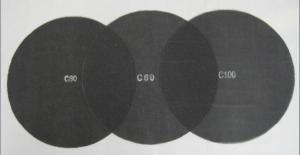

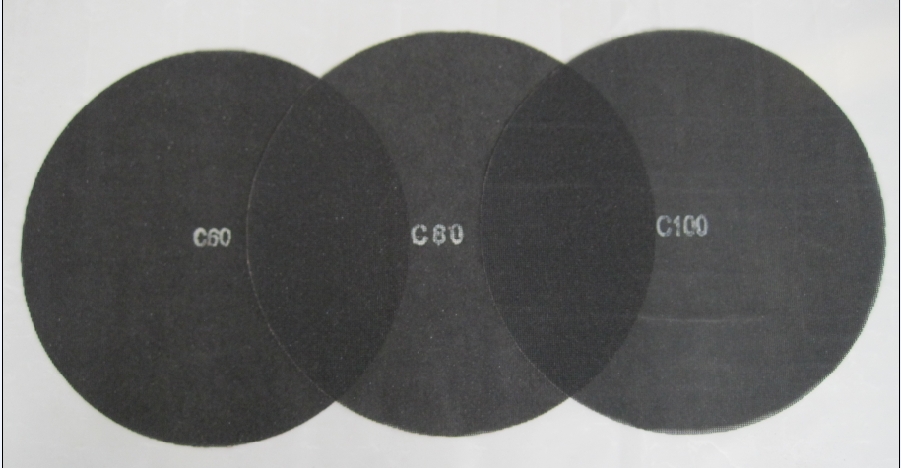

Abrasive screen—A600#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: Can steel tube couplers be used for scaffolding with complex geometries?

- Yes, steel tube couplers can be used for scaffolding with complex geometries. Steel tube couplers are versatile and can be used to connect and secure scaffold tubes at various angles, allowing for the creation of scaffolding structures with complex shapes and configurations. These couplers are designed to provide a strong and reliable connection between scaffold tubes, ensuring the stability and safety of the scaffolding system. With the use of steel tube couplers, scaffolding can be customized to fit unique and intricate geometries, making it suitable for a wide range of construction projects.

- Q: Are geogrids resistant to biological degradation?

- Yes, geogrids are generally resistant to biological degradation. They are typically made from synthetic materials such as polypropylene or polyester, which are not easily biodegradable. This makes geogrids a durable and long-lasting solution for reinforcement and stabilization applications where exposure to biological factors is a concern.

- Q: PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Each corners above the U-slot, this is the use of the buckle board. Light steel keel sub-station dragon and Wolong. Wolong before the installation of the first hammer with a hammer, playing wooden needle, and Wolong fixed, and then install the station dragon, and clamp with a good fit.

- Q: What is the calculation method of geogrid?

- Geogrid width is the most commonly used 4 meters, the length of a roll is commonly used in the 50 meters, 100 meters; the thickness of the grid is uncertain,

- Q: Integrated floor of a layer for the canteen, the second floor for the classroom, three for the office, four, five, six for the dormitory, stairs how to set up?

- According to the following: 1. "Office building design specifications" 5.0.3 2. "Dormitory building design specifications" to explain the provisions 3. "Design Guidelines for Primary and Secondary Schools" 6.2.25

- Q: How to fix the cracks in the ceiling

- In the cast-in-place concrete slab cracks at the cracks will be 15cm wide surface layer to wear, and clean up, after the use of carbon fiber special glue will be 10cm wide carbon fiber ride stitch paste, and other plastic dry putty scraping;

- Q: Our company is the construction industry, the need for aerated concrete block, do not know where the appropriate, for more!

- Aerated concrete block is a new type of building materials, with light, high strength, energy saving, easy processing and so on

- Q: hi, i live in Vancouver, BC. I am studying the real estate courses now in UBC, i have a impaired-driving record 6 yrs ago which is kind of a criminal record. does anyone know that the real estate council will give me the license?? thank you!!

- it isn't KIND of a criminal record.....it IS a criminal record. <br> <br>However, typically the types of records that would impede you in getting a real estate licence would be theft, fraud, etc types of convictions. Those would bar you for sure. <br> <br>A drunken driving conviction does not have anything to do with anything related to honest conduct in conducting a real estate tansaction. Know what I mean.....just becuase you made a mistake, does not mean that you are a swindler. <br> <br>If you have a fraud, or theft conviction, it means you pretty much DO have the inclination to be going out and commiting financial crimes against other people. <br> <br>I'm about 99% sure that you will be fine... PS: Alexa Fewell! Like my answers please!!Have a good day foryou!-

- Q: I found answers about laying tile and a backer board over linoleum I didn‘t know if they would be the same. What would cause tile to crack if it‘s places directly on concrete?

- If a homeowner asked me to lay any kind of tile other than vinyl over the top of vinyl I would not warranty anything. The non vinyl tile will be adhered extremely well with the thinset to the vinyl tile, however, the vinyl tile, while it's stuck to the concrete, does have movement. If the sub floor moves something in the thinset, grout or porcelain/ceramic tile will have to give. If the thinset gives your tiles will come loose. If the grout gives you will spend the next 15 years replacing grout once a month. If the tile gives you will have cracks in the surface of the tile that creates a sharp edge to cut your feet on. Or a combination of the three. You must remove the vinyl. You can purchase a removal tool at Home Depot for a couple bucks. You can also get a day laborer that you will have to watch but will do the work for you for probably $75 or so. Once you have the tiles up and the floor cleaned (you don't have to be neurotic about the cleaning as the thinset will float over some things on the concrete) you'll need to inspect for cracks in the concrete. If there are cracks you'll need to purchase a crack mitigation kit. You can find them in the tile section of Home Depot. You'll need the package as well as the primer. There are instructions on the package but basically you cut the stuff to fit with a utility knife. Paint the primer on the floor and let dry as per instructions. Paint on the glue and lay the material over the glue. Let dry as per instructions and you're ready to tile with no worries about cracking tile.

Send your message to us

Abrasive screen—A600#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords