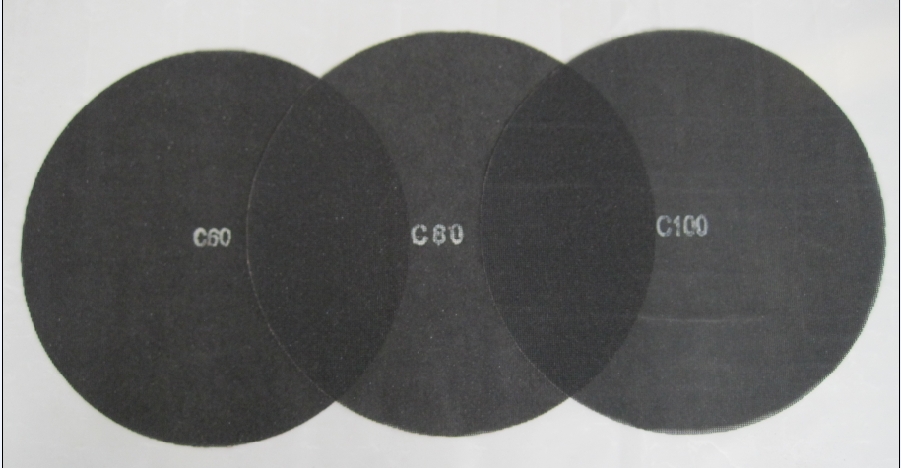

Abrasive screen —C40#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: Can a waterproofing membrane be used for underground utilities?

- Underground utilities can benefit from the use of a waterproofing membrane. These membranes are specifically designed to act as a barrier against water penetration, safeguarding the underlying structure from moisture damage. This becomes particularly significant for underground utilities, which face constant exposure to the surrounding soil and potential water seepage. Applying a waterproofing membrane to underground utilities, such as water pipes, sewer lines, or electrical conduits, aids in preventing water infiltration and subsequent corrosion or degradation of the materials. Acting as a protective layer, the membrane ensures that the utilities remain dry and free from moisture-related issues. Different types of waterproofing membranes are available, including sheet membranes, liquid membranes, and spray-applied membranes, each possessing unique properties and installation methods. The selection of the appropriate membrane relies on factors such as the specific utility, surrounding soil conditions, and additional requirements like chemical resistance or structural reinforcement. It is crucial to emphasize that proper installation and maintenance of the waterproofing membrane are vital for its effectiveness. Trained professionals should handle the installation, adhering to manufacturer guidelines and industry best practices. Regular inspections and maintenance are also necessary to ensure the membrane remains intact and functional over time. In conclusion, the utilization of a waterproofing membrane is indeed suitable for underground utilities. This application provides protection against water infiltration and preserves the integrity and longevity of the utilities.

- Q: Broken bridge aluminum doors and windows are generally how much?

- The broken bridge aluminum doors and windows are basically in accordance with the needs to carry out, according to your decoration when the doors and windows tailored,

- Q: Is it possible to utilize recycled fiberglass insulation in the production of new insulation products?

- <p>Yes, recycled fiberglass insulation can be used to make new insulation products. The process involves collecting and recycling old fiberglass insulation, which is then cleaned, shredded, and reprocessed into new insulation materials. This not only reduces waste but also conserves resources. However, it's important to ensure that the recycling process meets safety and quality standards to maintain the performance and integrity of the new insulation products.</p>

- Q: And if so, can it be used instead of poly cement, or are they used to glue different different things?

- Liquid poly is very liquid, it's useful for brushing onto large, flat surfaces or for very, very tiny parts, but generally normal poly cement is the thing to use. Never squeeze the tube! If you have to squeeze it means the nozzle is blocked; unblock the nozzle with a pin and hold the tube downward with the the the tiniest amount of pressure until the glue starts to flow. If you squeeze, there will be a 1 minute delay but then it'll come pouring out. Don't use poly cement unless you are sure you want a permanent weld; if you want a bond that can be broken apart (useful when you notice an error) use superglue or a hybrid epoxy. I use Zap-A-Gap quite a lot.

- Q: Light steel keel second ceiling

- Any light steel keel ceiling of the multi-level ceiling and complex modeling, multi-use wood core board and light steel keel convergence.

- Q: Can a waterproofing membrane be used in foundations?

- Yes, a waterproofing membrane can be used in foundations. In fact, it is often recommended to install a waterproofing membrane in foundations to prevent water infiltration and potential damage to the structure. The membrane is typically applied to the exterior walls of the foundation and acts as a barrier against water penetration. It helps to keep the foundation dry and protects it from hydrostatic pressure, which can cause cracks and leaks. Additionally, a waterproofing membrane can also prevent moisture buildup, mold growth, and other issues related to water damage. Overall, using a waterproofing membrane in foundations is an effective and reliable method to ensure the long-term durability and stability of a building.

- Q: Ps effect diagram of the building glass in the high light how to make

- In fact, downstairs that with the dodge tool is also possible. The Ps software is that you can use a lot of tools to complete the effect you want. Dodge tool where the range of intermediate tone, high light and other options. The Choose a high light will be a very bright rub. The Pay attention to excessive. The Can be used to fill the middle tone. The The And pay attention to exposure. The The The higher the exposure the more bright, wipe the effect of pure white is completely possible. The Suggest that you can use the middle tone to tune. The The When you paint by changing the exposure to achieve the desired effect.

- Q: Our bathroom vanity has 3 false drawer fronts, and I'm wondering how difficult it would be to install drawers. Is there a kit I could buy? Is it very difficult/expensive? Thanks.

- to be honest it may be easier to buy an new vanity.... Installing drawers can be challenging.....I am not aware of any kits... you will need to remove to false drawers.....install glides and make drawers.....

- Q: How about a pair of plates?

- Shuangyou I saw the online information is a wood company in Zhejiang, but the fame is not king coconut, Moganshan such a large brand of large plates. Influence is also inadequate.

- Q: Aluminum alloy doors and windows of the main structural components which ah

- The windows and doors are made up of three units: aluminum alloy, glass, fittings, aluminum alloy structure to be based on different ways to open, flat doors and windows, including frame materials and fan materials; sliding doors and windows include more, such as side seal, fixed Slippery, down, light, hook, top, bottom, etc. Glass is divided into hollow, double glass, coated, tempered, white glass, etc .; Accessories include handle, lock, hinge, pulley,

Send your message to us

Abrasive screen —C40#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords