Roll Aluminum Coil Michigan - AA8XXX Mill Finished Aluminum Coils D.C Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA8xxx Mill Finished Aluminum Coils D.C Used for Construction Description

AA8xxx Mill Finished Aluminum Coils D.C Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA8xxx Mill Finished Aluminum Coils D.C Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA8xxx Mill Finished Aluminum Coils D.C Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

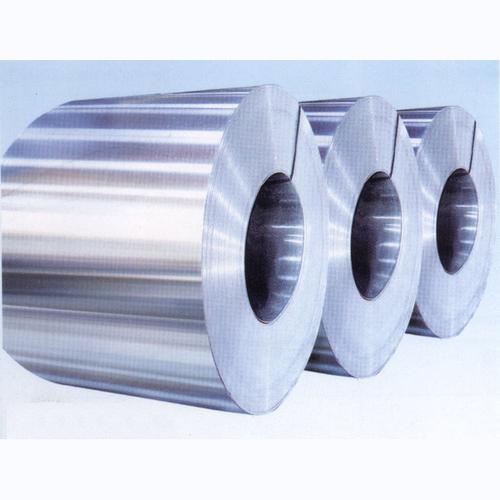

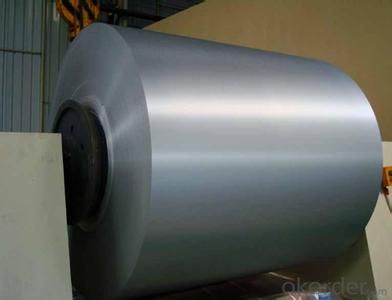

3.AA8xxx Mill Finished Aluminum Coils D.C Used for Construction Images

4.AA8xxx Mill Finished Aluminum Coils D.C Used for Construction Specification

| Alloy | AA8xxx (AA8011,AA8006 etc) |

| Temper | H14,H16,H18,H22,H24,H26,H32, O/F |

| Thickness | 0.2mm--100mm |

| Width | 30mm--1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of AA8xxx Mill Finished Aluminum Coils D.C Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum coils be used for food processing conveyor systems?

- Yes, aluminum coils can be used for food processing conveyor systems. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for food processing environments. Additionally, aluminum is non-toxic and does not react with food, ensuring the safety and quality of the processed products.

- Q: I'm wondering if there is a resin/molding material that can withstand the heat of melted aluminum for casting parts. I know that sand casting is the 'norm' but is there anything else? I'd rather not have to pack sand every time I want to cast a part.Thanks!

- One common mold material for metal casting is plaster mixed with silica sand to give it more strength. It needs to be completely (like heated) dry before you use it, but it is actually more work than sand casting but it gives a better finish. There are some rubber materials which can withstand the heat of casting pewter, but the melting point of pewter is so much lower than aluminum that I am sure those won't work for aluminum. I think you are pretty much stuck with sand for the easiest method.

- Q: Is it safe or practical to utilize aluminum coils in kitchen settings?

- <p>Aluminum coils can be used in the kitchen, but with certain considerations. They are often used in cookware due to their excellent heat conductivity, which allows for even heating. However, there are concerns about aluminum leaching into food, especially at high temperatures or in acidic environments, which could potentially have health implications. It's recommended to use aluminum cookware with a protective coating or to opt for cookware made from other materials like stainless steel or cast iron if there are health concerns. Always check the manufacturer's guidelines for safe usage and cleaning to ensure longevity and safety.</p>

- Q: What are the different coil packaging sizes available for aluminum coils?

- The customer's specific needs and requirements determine the available packaging sizes for aluminum coils. However, standard coil packaging sizes are generally found in the market. These sizes vary in dimensions and weights, ranging from small to large. Various common coil packaging sizes for aluminum coils include: 1. Small coils: These serve smaller applications or projects and typically have a diameter of 200-300mm and a weight of 50-150kg. 2. Medium coils: Suitable for medium-sized applications and projects, these coils usually have a diameter of 300-600mm and a weight of 150-500kg. 3. Large coils: Designed for larger applications or projects requiring a substantial amount of aluminum, these coils typically have a diameter of 600-1200mm and a weight of 500-2000kg. It's important to note that these are general guidelines, and the actual coil packaging sizes may vary depending on the manufacturer and specific customer requirements. Moreover, unique project needs often allow for the request of custom packaging sizes.

- Q: What is the role of aluminum coils in the automotive industry?

- Aluminum coils play a significant role in the automotive industry, particularly in the manufacturing of vehicles. These coils are used in the production of various components and parts, such as radiators, condensers, and air conditioning systems. One of the main reasons aluminum coils are preferred in the automotive industry is their lightweight nature. Aluminum is significantly lighter than other metals, such as steel, making it an ideal choice for improving fuel efficiency and reducing overall vehicle weight. This not only enhances the performance of the vehicle but also reduces emissions, contributing to a more environmentally friendly transportation sector. Additionally, aluminum coils offer excellent thermal conductivity, which is crucial in automotive applications. They help dissipate heat efficiently, ensuring the proper functioning of cooling systems and preventing overheating. This is particularly important for components like radiators, where effective heat transfer is essential to maintain optimal engine temperature. Furthermore, aluminum coils are highly corrosion-resistant. They have a natural oxide layer that protects against rust and corrosion, making them more durable and long-lasting than other metals. This resistance to corrosion is vital in the automotive industry, where vehicles are exposed to various environmental factors, such as moisture, salt, and chemicals. Aluminum coils also provide design flexibility. They can be easily shaped and formed into different sizes and configurations, allowing manufacturers to create complex and customized components. This flexibility in design enables automotive companies to optimize space and maximize efficiency in their vehicles. In summary, aluminum coils have a crucial role in the automotive industry. Their lightweight nature, excellent thermal conductivity, corrosion resistance, and design flexibility make them an ideal choice for various automotive applications, contributing to improved performance, fuel efficiency, and overall durability of vehicles.

- Q: i have about 100lbs of aluminum blocks and scrap.

- There is a BIG difference between the recycling refund on aluminum containers and the scrap value of other aluminum. The recycling refund is based upon deposits on beverage containers. It used to be that scrap dealers mentioned the amount of the deposit refund PLUS the scrap value of the cans. Now many of these slimy scuzz butts only REFUND the deposit and do not pay the scrap value! They keep that scrap payment for themselves as a windfall profit! The scrap value of aluminum doors, aluminum eating utensils, and so on is a set price. You will get only scrap market value for those. It will be handled separately. Try, as I did, putting aluminum foil in the drink cans and see what happens! I was doing it only because the aluminum foil was aluminum and would go to the same place. But, they have a count scanner that assesses the number and weight of the aluminum cans you bring in (the one I went to had it mounted above the conveyer belt where the shredder accepts the cans) and they can compare the weight of all of the cans to the count or basket capacity. Also, if they find shredded aluminum foil in the bin, they can analyze approximately who brought it in. They are also wise about putting water in the cans so they are heavier, but I never did that.

- Q: What are the different coil transportation options for aluminum coils?

- There are multiple transportation options available for aluminum coils, each offering their own advantages and suitability depending on various factors. These include: 1. Utilizing flatbed trucks: Commonly employed for aluminum coil transportation, flatbed trucks feature an open top and a flat, open trailer bed. To ensure secure transportation, the coils are firmly strapped or banded onto the bed, minimizing any potential movement. 2. Employing coil racks: Specifically designed for carrying aluminum coils, coil racks are specialized transportation equipment typically made of steel. These racks are placed within trucks or trailers, enabling the coils to be stacked and held in place by dividers, ensuring no shifting or damage occurs. 3. Opting for coil trailers: Specifically created for the transportation of aluminum coils, coil trailers possess a unique coil cradle system designed to securely hold the coils during transit. These cradles are adjustable, accommodating various coil sizes and preventing any potential movement or harm. 4. Considering container shipping: Another alternative for aluminum coil transportation involves the use of shipping containers. By loading the coils into the containers and securing them with straps or bracing, this option is frequently utilized for international transportation due to the ease of loading containers onto ships or trains. 5. Selecting rail transport: Rail transport presents an additional option for aluminum coil transportation, particularly for long-distance journeys. Specialized rail cars, known as coil cars, incorporate cradles or racks to securely hold the coils throughout the transit. This method is often chosen for its cost-effectiveness and efficiency. Ultimately, the selection of a suitable coil transportation option is dependent on factors such as distance, cost, and the specific requirements of the coils being transported.

- Q: Can aluminum coils be used in extreme weather conditions?

- Aluminum coils are capable of being utilized in the harshest weather conditions. With its exceptional durability and resistance to corrosion, aluminum proves to be a formidable material that can endure extreme heat, cold, humidity, as well as heavy rain or snow. Notably, it finds extensive employment in essential areas where weather resistance holds paramount importance, including air conditioning systems, refrigeration units, and outdoor equipment. These coils are expressly engineered to possess remarkable strength and dependability, ensuring their suitability for deployment in severe weather conditions, all the while maintaining optimal performance and lasting durability.

- Q: Can aluminum coils be used in automotive heat shields?

- Yes, aluminum coils can be used in automotive heat shields. Aluminum is a commonly used material in the manufacturing of heat shields due to its excellent heat resistance and lightweight properties. Aluminum coils can be formed and shaped into the desired design, allowing for easy installation and customization in automotive applications. Additionally, aluminum has high thermal conductivity, which helps to dissipate heat effectively, making it an ideal choice for heat shields in vehicles.

- Q: Can aluminum coils be used for magnetic purposes?

- No, aluminum coils cannot be used for magnetic purposes as aluminum is not a magnetic material.

Send your message to us

Roll Aluminum Coil Michigan - AA8XXX Mill Finished Aluminum Coils D.C Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords