1050 Aluminum Sheet Coil - AA3105 Prepainted Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA3105 Prepainted Aluminium Coils Used for Construction Description

AA3105 Prepainted Aluminium Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA3105 Prepainted Aluminium Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA3105 Prepainted Aluminium Coils Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

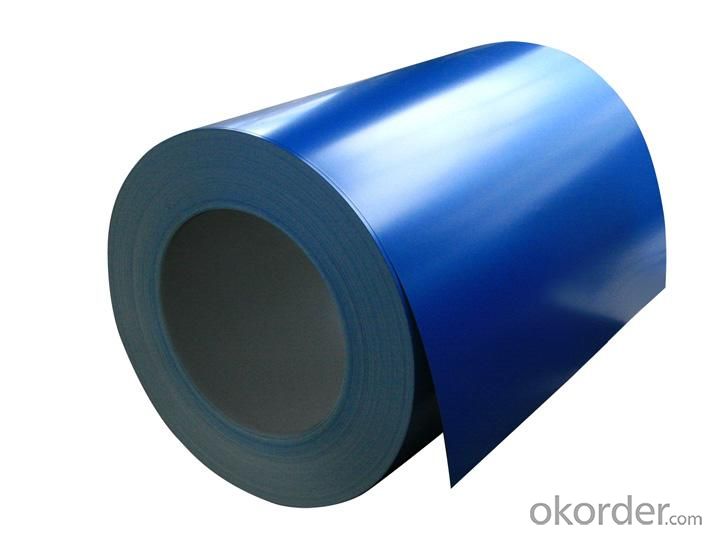

3.AA3105 Prepainted Aluminium Coils Used for Construction Images

4.AA3105 Prepainted Aluminium Coils Used for Construction Specification

Alloy | AA3105 |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2000mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum coils suitable for decorative applications?

- Yes, aluminum coils are suitable for decorative applications. Aluminum is highly malleable and can be easily shaped into various designs, making it a popular choice for decorative purposes. Additionally, aluminum is resistant to corrosion, lightweight, and has a natural sheen, which adds to its aesthetic appeal. Its versatility, durability, and availability in different colors and finishes make it an excellent material for decorative applications in various industries such as architecture, interior design, and automotive.

- Q: What are the different grades of aluminum used in coil production?

- The different grades of aluminum used in coil production typically include 1100, 3003, and 5052. These grades vary in terms of their composition and properties, allowing for specific applications and requirements in various industries.

- Q: Can aluminum coils be used in the manufacturing of electronic devices?

- Electronic devices can utilize aluminum coils due to their versatile nature and widespread use in various industries, including electronics. Transformers, inductors, and other components of electronic devices often incorporate aluminum coils. The lightweight nature of aluminum coils is one of their major benefits in electronic devices. Compared to materials like copper, aluminum is significantly lighter, making it easier to handle and transport. Moreover, aluminum possesses excellent thermal conductivity, promoting efficient heat dissipation within electronic devices. In addition, aluminum coils exhibit resistance to corrosion, which is vital in electronic applications where exposure to moisture or harsh environments is likely. This corrosion resistance plays a crucial role in extending the lifespan of electronic devices and ensuring their reliability. Furthermore, aluminum coils can be easily shaped and sized to fit various electronic device designs. This flexibility allows for customization to meet specific requirements, such as fitting into compact spaces or achieving desired electrical characteristics. In summary, aluminum coils offer numerous advantages in the manufacturing of electronic devices, including their lightweight nature, good thermal conductivity, resistance to corrosion, and flexibility in design.

- Q: What are the strength properties of aluminum coils?

- The strength properties of aluminum coils include high tensile strength, excellent formability, and good resistance to corrosion. Aluminum coils have a high strength-to-weight ratio, making them a preferred choice in various industries such as automotive, aerospace, and construction. They exhibit good resistance to fatigue and are capable of withstanding heavy loads without deformation or breakage. Additionally, aluminum coils offer excellent formability, allowing for easy shaping and bending without compromising their structural integrity. Moreover, aluminum's natural oxide layer provides a protective barrier against corrosion, making aluminum coils highly resistant to rust and other forms of degradation. Overall, the strength properties of aluminum coils make them a versatile and reliable material for a wide range of applications.

- Q: I have a diamond back bike with an aluminum frame. will it rust if i ride or put it in the frame? is it bad for the bike?

- No, but take care of it and it will stay looking good too. I keep mine inside. I clean and maintain it all the time! It's almost like a care, the better you take care of it, the better it will run.

- Q: What are the different types of protective coatings for aluminum coils?

- There are several types of protective coatings available for aluminum coils, including polyester, polyvinylidene fluoride (PVDF), acrylic, epoxy, and polyurethane. These coatings provide varying degrees of protection against corrosion, UV rays, and other environmental factors, ensuring the longevity and durability of the aluminum coils.

- Q: Can aluminum coils be insulated?

- Indeed, insulation can be applied to aluminum coils. It is a widespread practice to enhance energy efficiency and avoid heat loss or gain. Usually, the insulation material envelops the aluminum coil, creating a safeguarding coating that minimizes thermal transfer. This insulation method contributes to preserving the desired temperature within the coil and averting detrimental condensation. Moreover, insulation additionally enhances the overall functionality and durability of the aluminum coil system.

- Q: This question asks for an explanation of the various types of coatings that can be applied to aluminum coils.

- <p>Aluminum coils can be coated with several types of materials to enhance their properties for various applications. The main types include: 1. Anodized Coatings: These provide a protective oxide layer on the aluminum surface, enhancing corrosion resistance. 2. PVDF (Polyvinylidene Fluoride) Coatings: Known for their durability and resistance to UV rays, chemicals, and weathering. 3. Polyester Coatings: These are used for general-purpose applications due to their balance of properties like formability and chemical resistance. 4. PVF2 (Polyvinylidene Fluoride) Coatings: Similar to PVDF but with a thinner film, offering good weather resistance. 5. Acrylic Coatings: Known for their flexibility and adhesion, suitable for both interior and exterior applications. 6. Silane Coatings: Provide a thin, protective layer that enhances paint adhesion and corrosion resistance. Each type serves different purposes, and the choice depends on the specific requirements of the application.</p>

- Q: What are the different coil lengths available for aluminum coils?

- Aluminum coils come in a variety of lengths, depending on the specific application and requirements. Typically, these lengths range from a few feet to several hundred feet. The most commonly used coil lengths in industries like HVAC, automotive, and construction are 50 feet, 100 feet, and 250 feet. However, it is worth mentioning that custom coil lengths can also be produced to meet the customer's specific needs. These custom lengths may vary depending on factors such as coil thickness, width, and intended use. Ultimately, the available coil lengths for aluminum coils are adaptable and can be customized to meet the demands of various industries and applications.

- Q: What are the common problems faced with aluminum coils?

- There are several common problems that can be faced with aluminum coils. One of the most common issues is corrosion. Aluminum coils are susceptible to corrosion, especially when they are exposed to moisture. This can lead to the formation of rust or other types of corrosion, which can weaken the coil and affect its performance. Another common problem is coil damage. Aluminum coils can be easily damaged during handling or transportation. This can result in bent or dented coils, which can impact their efficiency and lifespan. In severe cases, the coil may even develop leaks or cracks, causing refrigerant or coolant to leak out. Clogging is another issue that can occur with aluminum coils. Over time, dust, dirt, and debris can accumulate on the coil, obstructing the airflow and reducing the coil's efficiency. This can result in poor cooling or heating performance, higher energy consumption, and increased wear and tear on the system. Additionally, aluminum coils can suffer from coil leaks. These leaks can occur due to a variety of reasons, such as physical damage, corrosion, or manufacturing defects. When a coil develops a leak, it can lead to refrigerant or coolant leakage, which can affect the overall performance of the HVAC system. Lastly, improper installation or maintenance practices can also cause problems with aluminum coils. If the coil is not installed correctly or if regular maintenance is neglected, it can lead to issues such as poor airflow, inefficient cooling or heating, and increased energy consumption. In order to avoid these common problems, it is important to properly maintain aluminum coils by regularly cleaning them, inspecting for any signs of damage or corrosion, and ensuring proper installation and handling. Regular maintenance and timely repairs can help minimize the occurrence of these problems and ensure the longevity and efficiency of the aluminum coils.

Send your message to us

1050 Aluminum Sheet Coil - AA3105 Prepainted Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords