5182 Aluminum Coils - Big Rolls of Aluminum Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

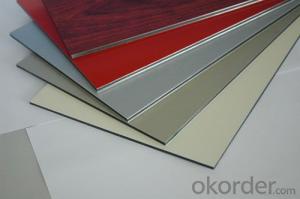

PEAluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

RawMaterial of the PE Aluminum Coating Coils:

1.Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy isavailable with AA3003, AA3005, AA5005 according to customer)

2. SurfacePaint: PE, PVDF and special paints.

Specificationof PE Aluminum Coating Coil

Width:20mm~1590mm

Thickness:0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coilweight: ≤ 4000kg

PE coatedaluminum coil is processed through the technics of roller coating and bakingwith precise polyester paints. Its color is glossy and with variety of colorsenabling you to choose easily. Chromatic aberration is small, impact resistanceis strong and easy to be processed, and all its performance has reached orsurpassed the national criteria. The products are widely used in indoor anddoor decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performanceof the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Colorof Card

PE (polyester)

PE

ColorMatch

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: How to sell the super hard 5083aluminum alloy and 5083 aluminum coil?

- Among the alloy which cannot endure heat treatment, 5083 aluminum alloy, a kind of high magnesium alloy, has the properties of intensity, machinability, anti-corrosion, electric-arc weldability and aesthetic after anodizing. The main element of 5083 alloy being magnesium, it is endowed with corrosion resistance, weldablility and moderate intensity, thus applicable to maritime areas such as ships, and cars, airplane weldments, metro light rail, and pressure vessel (such as liquid tank truck, refrigerated truck, refrigerated container), refrigerating equipment, television tower, drilling equipment, transport facility, missile parts, armor and so on.

- Q: How do aluminum coils contribute to sustainable transportation?

- Aluminum coils play a crucial role in promoting sustainability in transportation through several means. Firstly, the lightweight nature of aluminum makes it a perfect choice for various vehicle components, replacing heavier materials like steel. This substitution reduces the overall weight of the vehicle, consequently enhancing fuel efficiency and minimizing greenhouse gas emissions. Furthermore, the inclusion of aluminum coils in vehicle manufacturing enhances the vehicle's durability and longevity. Aluminum's excellent resistance to corrosion proves especially beneficial in areas with harsh weather conditions or high levels of road salt. The extended lifespan of vehicles constructed with aluminum coils results in reduced repair requirements and replacements, thereby minimizing waste generation and resource consumption throughout the vehicle's lifetime. Additionally, the recyclability of aluminum significantly contributes to sustainable transportation. As one of the most recyclable materials worldwide, nearly 75% of all aluminum ever produced remains in use today. Manufacturers can incorporate recycled aluminum into their production processes by utilizing aluminum coils, thereby reducing the need for primary aluminum extraction. This practice not only conserves natural resources but also mitigates energy consumption and greenhouse gas emissions associated with aluminum production. Moreover, aluminum coils support sustainable transportation by enabling the advancement of electric vehicles (EVs). The lightweight nature of aluminum aids in improving the energy consumption and overall efficiency of EVs. Furthermore, the exceptional thermal conductivity of aluminum facilitates better heat dissipation in EV batteries, resulting in enhanced performance and longevity. In summary, the utilization of aluminum coils in transportation contributes to sustainability efforts by reducing vehicle weight, enhancing fuel efficiency, increasing durability, promoting recycling, and facilitating the growth of electric vehicles. As the transportation sector continues to strive for emission reduction and increased efficiency, aluminum coils will remain a vital component in achieving these sustainability goals.

- Q: What is the typical thickness of aluminum coils?

- The intended use and application of aluminum coils can result in varying thicknesses. Generally, a range of thicknesses is accessible, spanning from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm). The specific thickness needed for a specific project or industry hinges on factors like desired strength, flexibility, and weight of the aluminum coils.

- Q: Can aluminum coils be used in the production of chemical storage tanks?

- Aluminum coils, indeed, have the potential to be utilized in the manufacturing process of chemical storage tanks. Aluminum, being an adaptable and long-lasting material, presents numerous advantages when it comes to chemical storage applications. Its resistance to corrosion renders it suitable for the storage of a vast array of chemicals. Moreover, its lightweight nature facilitates transportation and installation in contrast to materials such as steel. Furthermore, its non-magnetic properties can prove advantageous in certain scenarios. Nevertheless, it is crucial to carefully assess the specific demands of the chemicals being stored and seek advice from professionals or manufacturers to ensure that aluminum is the appropriate choice for the intended purpose.

- Q: Aluminum inventory of the company, placed for a little longer, there will be surface oxidation, white spot shape, after cleaning into black spots, affecting the use of. Is there a better and convenient way to save it?

- In general, aluminum itself. You said that the antioxidant warehouse is wet, there are other acidic substances damage the alumina compact protection film. Aluminum volume convenient paint, or wrapped in a plastic film, the best conditions inside the silicon desiccant

- Q: What is the maximum temperature that aluminum coils can withstand?

- The maximum temperature endurance of aluminum coils is determined by several factors, including the specific alloy composition, thickness, and application. In general, aluminum coils are renowned for their remarkable heat conductivity and ability to resist high temperatures. Frequently utilized aluminum alloys, such as 3003 or 5052, can endure temperatures of approximately 300-350 degrees Fahrenheit (150-175 degrees Celsius) without experiencing significant deformation or damage. Nevertheless, it is important to be aware that surpassing this temperature range can compromise the structural integrity of the aluminum coils, resulting in distortion, melting, or even combustion. Moreover, prolonged exposure to elevated temperatures can also diminish the overall strength and performance of the aluminum coils. Therefore, it is essential to refer to the manufacturer's specifications and guidelines for the specific aluminum alloy and application in question to ascertain the maximum safe temperature limit that the coils can withstand.

- Q: How are aluminum coils tested for quality control?

- Aluminum coils go through numerous quality control tests to ensure their reliability and performance. One primary test is the dimensional inspection, where the coils' physical dimensions are measured and compared to the manufacturer's specifications. This helps identify any discrepancies in length, width, thickness, or diameter. Another critical test is the visual inspection, where the coils are thoroughly examined for surface defects like scratches, dents, or discoloration. This visual examination is crucial to ensuring that the coils meet the required aesthetic standards. To evaluate the mechanical properties, various mechanical tests are conducted. Tensile strength tests measure the coils' resistance to breaking under tension, determining their durability and strength. In addition, hardness tests assess the coils' resistance to indentation or deformation. The hardness values are compared to predetermined standards to verify if the coils meet the necessary criteria. Corrosion resistance testing is also conducted to assess the coils' ability to withstand corrosion over time. This test exposes the coils to harsh environments or corrosive substances, which is crucial as aluminum is often used in applications that may involve contact with corrosive elements. Electrical conductivity tests ensure the proper functioning of the coils in electrical applications. Conductivity is measured and compared to the required specifications to guarantee that the coils possess the desired electrical characteristics. Additionally, depending on the specific requirements of the aluminum coils, other tests like chemical composition analysis, surface roughness evaluation, and coating adhesion tests may also be performed. Overall, these comprehensive quality control tests enable manufacturers to ensure that aluminum coils meet necessary standards, ensuring their quality, performance, and reliability in various applications.

- Q: What is the maximum operating temperature for aluminum coils?

- The maximum operating temperature for aluminum coils typically ranges from 200 to 250 degrees Celsius.

- Q: This question asks about the environmental effects associated with the use of aluminum coils.

- <p>The environmental impacts of using aluminum coils include energy consumption during production, potential release of greenhouse gases, and waste generation. Aluminum production requires significant energy, contributing to carbon emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. However, aluminum is highly recyclable, and recycling it saves energy and reduces waste. Proper disposal and recycling practices can mitigate some of these impacts, making aluminum a more sustainable choice when managed correctly.</p>

- Q: Can aluminum coils be used in electrical applications?

- Indeed, aluminum coils possess the capability for utilization in electrical applications. Its abundance in electrical wiring is attributable to its cost-effectiveness and superior conductivity in comparison to copper. Transformers, motors, generators, and other electrical apparatuses commonly rely on aluminum coils. Nevertheless, it is essential to acknowledge that copper surpasses aluminum in terms of electrical conductivity, necessitating the use of larger aluminum coils to attain equivalent levels of conductivity. Moreover, the implementation of specialized insulation and connectors becomes imperative for aluminum coils to prevent corrosion and guarantee appropriate electrical connections.

Send your message to us

5182 Aluminum Coils - Big Rolls of Aluminum Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords