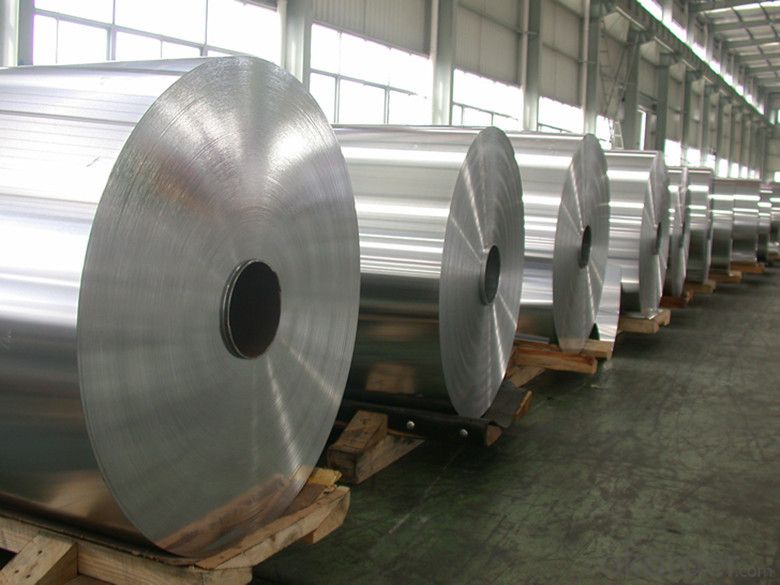

Brushed Aluminum Sheets Houston - 5083 Aluminum Coil and Foil Strip Household Aluminum Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.20 years OEM service, custom order available

2.Excellent barrier

3.FDA, SGS

Material: Different materials available for option - Food grade

Glossy finish: PET/AL/PE, PET/VMPET/PE, OPP/VMPET/PE

Transparent: PET/PE, NY/PE,PET/CPP

Matte finish: OPP/AL/PE,PET/CPP, PET/NY/PE

More Details

1. Original factory price, high quality, fast delivery.

2. ISO9001:2008; ISO14001:2004.

3. Material: PET/ AL/ PE; NY/AL/PE,OPP/CPP,PE/PET.etc.

4.Moisture proof, oxygen barrier, nontoxic.

5. Available in different material to suit for different products’ package

6.Customized structures, size, styles are welcome.

FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can aluminum sheets be used for modular construction?

- Yes, aluminum sheets can be used for modular construction. Aluminum is a versatile and lightweight material that offers several benefits for modular construction projects. It is durable, corrosion-resistant, and has a high strength-to-weight ratio, making it suitable for various structural applications. Aluminum sheets can be easily fabricated and formed into different shapes and sizes, allowing for flexibility in design and construction. Additionally, aluminum is recyclable, making it an environmentally friendly choice for sustainable construction practices. Overall, aluminum sheets are a viable option for modular construction due to their strength, durability, and versatility.

- Q: What are the standard dimensions of aluminum sheets?

- The standard dimensions of aluminum sheets vary depending on the specific application and industry. However, common sizes for aluminum sheets typically range from 0.02 to 0.25 inches in thickness and from 24 to 48 inches in width and length.

- Q: what’s the difference of activated aluminum and aluminum sheet?

- contain more water and activated

- Q: I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- Aluminium is one of the most abundant Element on earth, ranking 3rd in the crust, second only to oxygen and silicon. And it is eminently recyclable. However, many minerals containing aluminium are not economically exploitable.

- Q: What is the standard thickness of aluminum sheets used for constructing carports or garages?

- <p>The thickness of aluminum sheets commonly used for carports or garages typically ranges from 0.022 to 0.032 inches (0.56 to 0.81 mm). This range provides a balance between strength and cost-effectiveness. Thicker sheets offer greater durability and resistance to weathering, while thinner sheets are more affordable but may require more maintenance over time. The specific thickness chosen often depends on the design requirements, local weather conditions, and the intended lifespan of the structure.</p>

- Q: Are aluminum sheets suitable for HVAC systems?

- Yes, aluminum sheets are suitable for HVAC systems. Aluminum is a lightweight and durable material that provides excellent thermal conductivity, making it ideal for use in HVAC systems. It is commonly used for making ductwork, heat exchangers, and fins in air conditioning units. Aluminum sheets are corrosion-resistant, which is advantageous in environments with high humidity or exposure to moisture. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for HVAC systems. Overall, aluminum sheets offer numerous benefits and are widely used in the HVAC industry.

- Q: hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- OK. the first thing is that you can connect copper to aluminum. They make wire that is called copper clad aluminum and is exactly what it sounds like, but you don't have to install that. So if you want to install a junction box just make sure that it remains exposed and that you secure the wire within 12 inches of the box. About your light. I would simply put up another fixture, just make a visual inspection of the wire. if it is all roughly the same shade then it is most likely still fine. The only damage that is done by replacing a fixture to much is to the wire that is inside of the box and if something happens to that it will not start a fire, the light simply won't work.

- Q: Are aluminum sheets suitable for electrical applications?

- Yes, aluminum sheets are suitable for electrical applications. Aluminum has excellent electrical conductivity, making it a popular choice for various electrical components and wiring. It is lightweight, corrosion-resistant, and can efficiently dissipate heat, making it appropriate for electrical applications where these properties are desired.

- Q: How are aluminum sheets cleaned and maintained?

- Achieving effective cleanliness and maintenance for aluminum sheets can be accomplished through a straightforward process. To commence, it is crucial to eliminate any loose dirt or debris from the sheet's surface. This can be accomplished by utilizing a soft brush or cloth to gently sweep away the particles. Subsequently, a mild detergent solution can be concocted by combining a small quantity of dish soap or a specialized aluminum cleaner with warm water. This solution ought to be applied to the sheets utilizing a soft sponge or cloth. It is essential to steer clear of abrasive materials or cleaners containing harsh chemicals, as these may inflict harm upon the aluminum surface. Once the detergent solution has been applied, the sheets should be thoroughly rinsed with clean water to eradicate any residue. It is pivotal to guarantee the complete removal of all soap or cleaner, as any remaining residue could result in staining or discoloration over time. Upon ensuring the sheets are clean, they should be dried using a clean, soft cloth or towel. This measure aids in preventing the formation of water spots or streaks on the surface. It is imperative to refrain from utilizing abrasive materials or engaging in vigorous rubbing, as this could lead to scratches on the aluminum. Regarding maintenance, it is advisable to regularly inspect the aluminum sheets for any indications of damage or corrosion. If any areas are discovered to be compromised, immediate repair or replacement should be undertaken to prevent further deterioration. Furthermore, applying a protective coating to the aluminum sheets is advantageous. This can be achieved by employing a specialized aluminum sealant or a clear lacquer. Such a coating serves to safeguard the surface against environmental factors like moisture, sunlight, and pollutants. In conclusion, the process of cleaning and maintaining aluminum sheets necessitates gentle and regular cleaning with a mild detergent solution, thorough rinsing, and drying with a soft cloth. Additionally, inspecting for damage and applying a protective coating can contribute to extending the longevity and enhancing the appearance of the sheets.

- Q: Can the aluminum sheets be used for manufacturing door frames?

- Indeed, door frames can be manufactured using aluminum sheets. Aluminum, a versatile material, finds extensive usage in the construction field owing to its robustness, longevity, and lightweight nature. It can be conveniently molded, curved, and joined through welding processes to fashion door frames of diverse dimensions and styles. Furthermore, aluminum possesses exceptional resistance against corrosion, rendering it suitable for both indoor and outdoor applications. In conclusion, employing aluminum sheets for the production of door frames represents a sensible and widely favored option within the construction sector.

Send your message to us

Brushed Aluminum Sheets Houston - 5083 Aluminum Coil and Foil Strip Household Aluminum Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords