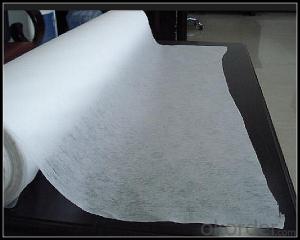

500g Nonwoven Polyester Staple Fiber Geotextile Tape Fabric Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

geotextiles are permeable nonwoven fabrics used to separate, filter, reinforce, protect, or drain. Geotextiles allow filtration / separation of granular layers in roads and rail applications, used to protect membranes in landfill applications, used in coastal defence applications and used in Landscaping to protect surfaces and structures from weeds and root growth.

Applications

Filtration

gabions and river mattresses

roads

concrete retaining walls.

Separation

the separation of good and poor roadway layer work materials

roads over soft soils.

Roadway lining

provides waterproofing qualities for layer works and wearing courses.

Drainage of

sports fields

railway tracks

behind concrete walls & embankments.

Membrane liner protection

gabion structures

landfill sites.

geotextiles are permeable nonwoven fabrics used to separate, filter, reinforce, protect, or drain. Geotextiles allow filtration / separation of granular layers in roads and rail applications, used to protect membranes in landfill applications, used in coastal defence applications and used in Landscaping to protect surfaces and structures from weeds and root growth.

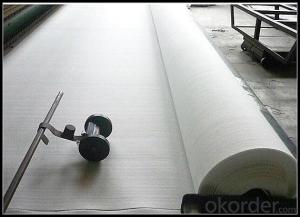

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the purpose of using geotextiles?

- The purpose of using geotextiles is to provide a wide range of functions in different construction and engineering applications. These functions include soil stabilization, erosion control, filtration, drainage, separation, and reinforcement. Geotextiles act as a protective barrier, improving the performance and lifespan of infrastructure projects such as roads, embankments, retaining walls, and landfills.

- Q: Above a geotextile one, that there is any acceptance of norms?

- Detailed advice vx, zhang my side is the manufacturers, welcome advice, Insider!

- Q: Geotextile testing standards

- Staple stitch filament piercing filament woven weaving

- Q: How do geotextiles help in preventing erosion around culverts?

- Geotextiles help prevent erosion around culverts by acting as a protective barrier that stabilizes the surrounding soil. They are installed to prevent soil movement and filter out any sediments, allowing water to flow freely while retaining the integrity of the soil structure. This helps to prevent erosion, maintain the stability of the culvert, and enhance its overall longevity.

- Q: What are the cost implications of using geotextiles in construction projects?

- The cost implications of using geotextiles in construction projects can vary depending on factors such as the type and quality of the geotextile, the size and complexity of the project, and the specific requirements of the site. Geotextiles can contribute to cost savings by reducing the need for traditional construction materials, such as aggregate or soil, and by improving the longevity and performance of the project. Additionally, geotextiles can help minimize maintenance and repair costs by providing erosion control, drainage, and stabilization. However, the initial investment in geotextiles and their installation may increase upfront costs compared to traditional construction methods. Overall, a thorough cost-benefit analysis should be conducted to determine if using geotextiles is financially advantageous for a specific construction project.

- Q: What is the meaning of the geotextile What is its working principle

- Hot geotextile cloth is to isolate the heat and cover a layer of geotextile material. Advantages: light weight, the overall continuity is good, high tensile strength, corrosion resistance, anti-microbial erosion is good, easy construction. Non-woven geotextile properties: small pore diameter, good permeability, soft texture, and soil with a good combination. 2, construction (1) according to the embankment or base wide full section laying. (2) leave sufficient anchorage length on each side of the embankment or substrate. (3) To ensure integrity, when the lap method is continuous, the lap length should be 0.3 ~ 0.5m. When the seam is connected, the bond width is not less than 50mm. (4) site construction, material damage must be immediately repaired. Upper and lower seams should be alternately staggered, staggered length of not less than 0.5m. (5) try to avoid prolonged exposure.

- Q: Geotextile seepage seams how to deal with

- Quick drying cement

- Q: What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by interlacing yarns or fibers together in a regular pattern, creating a strong and durable fabric. Non-woven geotextiles, on the other hand, are manufactured by bonding or felting fibers together, forming a random web-like structure. This results in a fabric that is less strong but offers excellent filtration and drainage properties. In summary, woven geotextiles are stronger and more suitable for applications requiring high tensile strength, while non-woven geotextiles are ideal for filtration and drainage purposes.

- Q: What are the factors to consider when selecting geotextiles for a specific project?

- When selecting geotextiles for a specific project, there are several factors that need to be considered. These include the type of soil and its properties, the intended purpose of the geotextile, the required strength and durability, the environmental conditions, and the installation and maintenance requirements of the project. Additionally, factors such as cost, availability, and the reputation of the manufacturer should also be taken into account.

- Q: Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

Send your message to us

500g Nonwoven Polyester Staple Fiber Geotextile Tape Fabric Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords