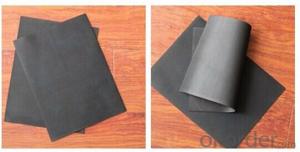

4m wide EPDM pond liner weldable with good quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

| EPDM waterproof membrane is made from ternary ethylene-propylene

rubber, which is for waterproofing of exposed and non-exposed applications.

| EPDM waterproof membrane production adopts the world-advanced equipment of

cold feeding extrusion and continuous vulcanization technology.

| EPDM waterproof membrane is of high elasticity among high polymer waterproof materials

and becomes a world-popular waterproofing material.

2. Specification

1) Material: EPDM Rubber

2) Size: 1.2m/2m/3m/4m (width)*20m (length) or customized,

3) Thick: 1.2mm, 1.5mm, 2.0mm

4) Type: Weldable

5) Pattern: Non-reinforced (homogeneous)

6) Certificate: ISO9001/14001

3. Features

| Excellent physical and mechanical performance

| High tearing resistance

| Good deformation adaptability

| High puncture resistance

| High aging resistance

- Q: Is a waterproofing membrane resistant to cracking or shrinking?

- Yes, a waterproofing membrane is typically resistant to cracking and shrinking. The purpose of a waterproofing membrane is to create a barrier that prevents water from penetrating through surfaces, such as roofs, walls, or foundations. To achieve this, these membranes are usually made from flexible and durable materials, such as modified bitumen, PVC, EPDM, or polyurethane. These materials have inherent properties that allow them to withstand various environmental conditions, including temperature fluctuations, UV radiation, and physical stresses. This resilience ensures that the waterproofing membrane remains intact and stable, even when exposed to challenging conditions. Furthermore, waterproofing membranes are engineered to be highly resistant to cracking and shrinking. They are designed to accommodate movements and structural changes that may occur in the building or substrate over time. This flexibility helps to prevent the membrane from cracking or tearing, even if there are minor shifts or settling in the structure. Moreover, waterproofing membranes undergo rigorous testing and quality control measures during their manufacturing process to ensure their durability and resistance to cracking and shrinking. These tests simulate real-world conditions, including temperature changes, elongation, and compression, to verify the membrane's performance and longevity. However, it is important to note that the quality and performance of a waterproofing membrane can vary depending on the specific product and manufacturer. It is crucial to choose a reliable and reputable brand and ensure proper installation and maintenance to maximize the membrane's resistance to cracking or shrinking.

- Q: Can a waterproofing membrane be recycled or disposed of in an environmentally friendly manner?

- Yes, a waterproofing membrane can be recycled or disposed of in an environmentally friendly manner. Many waterproofing membranes are made from recyclable materials such as polyethylene or polypropylene, which can be recycled into new products. Recycling these membranes not only reduces waste but also conserves resources and reduces the environmental impact of manufacturing new materials. To recycle a waterproofing membrane, it is important to check with local recycling facilities or waste management centers to see if they accept this type of material. Some facilities may have specific guidelines or processes for recycling membranes, so it is crucial to follow their instructions. In cases where recycling is not feasible, disposing of the waterproofing membrane in an environmentally friendly manner is still possible. Many waste management facilities have designated areas for construction and demolition waste, where the membrane can be properly disposed of. These facilities employ techniques to minimize the impact of the waste on the environment, such as containment and controlled disposal methods. It is essential to avoid disposing of the membrane in regular trash or dumping it illegally, as this can harm the environment and contribute to pollution. Proper disposal ensures that any potential pollutants or contaminants in the membrane are managed appropriately, preventing harm to ecosystems and human health. Overall, by recycling or disposing of a waterproofing membrane in an environmentally friendly manner, we can contribute to a more sustainable and cleaner future.

- Q: Can a waterproofing membrane be used on gypsum board surfaces?

- Yes, a waterproofing membrane can be used on gypsum board surfaces. Gypsum board, also known as drywall, is a common material used in interior construction. While it is not inherently waterproof, applying a waterproofing membrane can help protect the gypsum board from moisture damage. A waterproofing membrane is a thin layer of material that is applied to the surface of the gypsum board. It forms a barrier that prevents water from seeping into the board and causing it to deteriorate or mold. It can be used in areas where moisture is present, such as bathrooms, kitchens, laundry rooms, or basements. Before applying a waterproofing membrane, it is important to prepare the gypsum board surface properly. This may involve cleaning the surface, patching any holes or cracks, and ensuring the board is dry and free of dust. Once the surface is ready, the waterproofing membrane can be applied according to the manufacturer's instructions. It is worth noting that while a waterproofing membrane can provide some protection against moisture, it is not a guarantee against water damage. It is always important to address the source of water intrusion and ensure proper drainage and ventilation in any area prone to moisture. Additionally, it is recommended to consult with a professional or follow the manufacturer's recommendations when choosing and applying a waterproofing membrane to gypsum board surfaces.

- Q: Can a waterproofing membrane be used on sloped roofs?

- Yes, a waterproofing membrane can be used on sloped roofs. Waterproofing membranes are designed to provide a protective barrier against water penetration, and their flexibility allows them to conform to the shape of sloped roofs effectively. This helps prevent water from seeping into the structure and causing damage.

- Q: Can a waterproofing membrane be used on tunnels with architectural features?

- Yes, a waterproofing membrane can be used on tunnels with architectural features. Waterproofing membranes are versatile and can be applied to various types of structures, including tunnels with architectural features. These membranes are designed to create a barrier against water infiltration, protecting the structure from moisture damage. Whether the tunnel has unique architectural features such as curves, arches, or decorative elements, a waterproofing membrane can be customized and applied to ensure complete waterproofing. It is essential to consult with a professional waterproofing contractor who has experience in working with tunnels and architectural features to determine the most suitable membrane system for the specific project requirements.

- Q: Can a waterproofing membrane be installed on vertical surfaces without sagging or slumping?

- Yes, a waterproofing membrane can be installed on vertical surfaces without sagging or slumping. There are specific waterproofing membranes available in the market that are designed to adhere to vertical surfaces and maintain their shape and integrity. These membranes are typically made of materials that have a higher viscosity, allowing them to stick to the vertical surface and resist sagging or slumping. Additionally, some membranes may also have reinforced layers or mesh embedded within them to provide extra support and prevent sagging or slumping. Proper installation techniques, such as ensuring a clean and dry surface, using appropriate adhesives, and following manufacturer guidelines, are also crucial in ensuring that the waterproofing membrane adheres properly and does not sag or slump.

- Q: Can a waterproofing membrane be used for convention centers or exhibition halls?

- Yes, a waterproofing membrane can be used for convention centers or exhibition halls. Waterproofing membranes are commonly used in construction to protect buildings from water damage and leakage. Given the potential for water infiltration in large spaces like convention centers or exhibition halls, using a waterproofing membrane can help ensure the integrity and durability of the structure by preventing water penetration and potential damage.

- Q: Can a waterproofing membrane be used for a bridge?

- Yes, a waterproofing membrane can be used for a bridge. Waterproofing membranes are commonly used in bridge construction to prevent water infiltration and protect the structure from deteriorating due to moisture. These membranes act as a barrier against water and can significantly extend the lifespan of bridges by preventing corrosion and structural damage caused by water exposure.

- Q: Can a waterproofing membrane be installed in areas with high humidity?

- Installing a waterproofing membrane is possible in areas with high humidity. In fact, high humidity can contribute to the necessity of waterproofing due to the possibility of moisture accumulation and potential water damage. Regardless of the humidity levels, waterproofing membranes are designed to establish a barrier against water infiltration. Nonetheless, it is crucial to guarantee the correct installation and sealing of the membrane to prevent any moisture seepage. Moreover, in areas with high humidity, it might be essential to adopt additional measures like utilizing moisture barriers or dehumidifiers to provide further protection against potential water damage.

- Q: Can a waterproofing membrane be installed on a roof?

- Yes, a waterproofing membrane can be installed on a roof. A waterproofing membrane is a type of material that is specifically designed to provide a protective layer on a surface, preventing water from seeping through. When installed on a roof, a waterproofing membrane acts as a barrier against moisture, preventing leaks and water damage to the underlying structure. It is commonly used in flat or low-sloped roofs, where water can accumulate and cause issues. The installation process typically involves cleaning and preparing the roof surface, applying the membrane in overlapping layers, and securing it with adhesives, fasteners, or heat welding. Additionally, a waterproofing membrane can also help in extending the lifespan of a roof by protecting it from UV rays, temperature fluctuations, and other environmental factors. Overall, installing a waterproofing membrane on a roof is an effective way to ensure its long-term durability and prevent water-related problems.

Send your message to us

4m wide EPDM pond liner weldable with good quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords