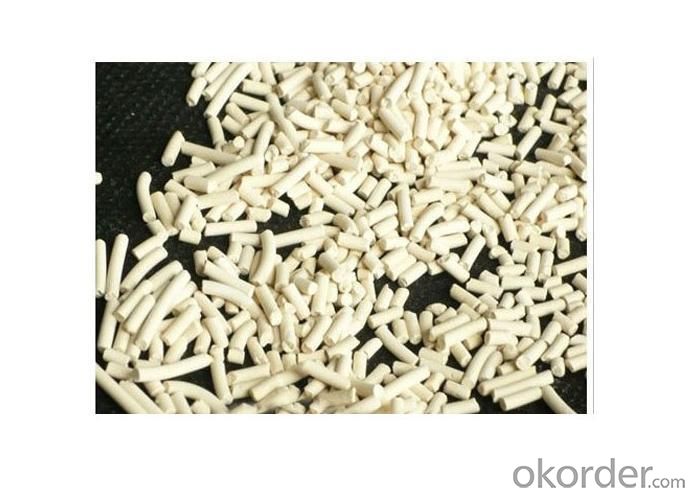

4A Molecular Sieve with Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton m.t.

- Supply Capability:

- 10000 Metric Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. For drying and purifying, high efficient

2. Prefessional manufacturer

3. FREE SAMPLES at any time

Molecular sieve 4A is an alkali alumino silicate;it is the sodium form of the Type A crystal strcture.4A molecular sieve has an effective pore opening of about 4 angstroms(0.4nm).Our 4A molecular sieve will adsorb most molecules with a kinetic diameter of less than 4 angstroms and exclude those larger.Such adsorbable molecules include simple gas molecules such as oxygen,nitrogen,carbon dioxyde and straight chain hydrocarbons.Branched chain hydrocarbons and aromatics are excluded.

Molecular Formula

Na2O Al2O3 2.0 SiO2 4.5 H2O

Specification And Application

Specification | |||||

Item |

Unit |

Technical data | |||

Shape |

|

Pellet |

Sphere | ||

Diameter |

mm |

1.5-1.7 |

3.0-3.3 |

1.7-2.5 |

3.0-5.0 |

Size Ratio Up To Grade |

% |

≥98 |

≥98 |

≥96 |

≥96 |

Bulk Density |

g/ml |

≥0.66 |

≥0.66 |

≥0.66 |

≥0.66 |

Wear Ratio |

% |

≤0.20 |

≤0.40 |

≤0.20 |

≤0.20 |

Crushing Strength |

N |

≥30/cm |

≥45/cm |

≥30/p |

≥70/p |

Static Water Adsorption |

% |

≥20.5 |

≥20.5 |

≥21 |

≥21 |

Ethylene Adsorption |

% |

≤3.0 |

≤3.0 |

≤3.0 |

≤3.0 |

Water Content, As Shipped |

% |

≤1.5 |

≤1.5 |

≤1.5 |

≤1.5 |

Application | |||||

Drying and removing of CO2 from natural gas, LPG, air,inert and athmospheric gases, etc. | |||||

Removal of hydrocarbons, ammonia and methanol from gas streams (ammonia syn gas treating). | |||||

Special types are used in the air break units of buses, trucks and locomotives. | |||||

Packed in small bags, it may be used simply as a packaging desiccant. | |||||

Attention | |||||

To avoid damp and pre-adsorption of organic before running, or must to be reactivated. | |||||

- Q: I am putting tile on the wall in my bathroom (not in the shower), do i have to put cement board behind it?or can i just leave the drywall that is already there?

- Cement board is normally needed where directly in contact with moisture. I wouldn't change out your existing drywall.

- Q: Question such as the title, the building which area also used in which aspects of the material? Questions added: What should I pay attention to buying these materials? How can we make money in it? More

- Where are you? The price of each place are not the same, the gap is very large. I suggest you go directly to your building materials market 禒 Fan exercises both Ge Huan fork only to ask. Selling these things are very concentrated, so run a place on it.

- Q: should i get white cement 4's or galaxy foamposites?

- The white cement 4's because its gonna be hella hard to get ur hands on the galaxy foamposites there gonna be super limited quick strike but good luck on all accounts.

- Q: How many bags of cement do you have in 1 cubic meter of concrete mixed in the ratio 1:4:8?

- 1 bag of cement contains 1ft^3. divide 1 cubic meter into 13 parts. 1 part cement, 4 parts fine aggregate and 8 parts course aggregate. 1cubic meters of concrete/13= 0.0769 cubic meters Since cement is only 1 part then you will need 0.0769 cubic meters of cement. 0.0769m^3 ( 3.39ft/1m)^3= 2.996 ft^3 of cement Therefore you would need 3 bags of cement for a cubic meter of concrete.

- Q: I need to glue a small plastic piece to another plastic piece, will the cement work? What are the steps in gluing and making sure the glue holds?

- Barge Cement

- Q: Eucalyptus leaves were left on the front porch. It rained. Evidently, they are treated with some type of coloring agent and it dripped from the leaves to the porch cement leaving a bluish stain. The tint washed right off my hands, but not so with the cement which absorbed it like an easter egg.I've tried soap and water -- no good.Krud Kleaner with a wire brush -- faded it a little.OxyClean with a toothbrush -- faded it a little more.But, the stain is still there and very visible. Is there anything that will get it out? Bleach, maybe...vinegar ???Help!Thanks.

- I would try bleach, and let it sit on the concrete for a while. I know they sell cement cleaners in home improvement stores like Lowe's and Home Depot, you may want to check those out.

- Q: its for my physics assignment..thanks!

- It can insulate against electromagnetic energy due to the limestone in the cement. Like ceramic. As far as being a temperature insulator, the cement wall gets very cold in the winter, so it's not a good insulator for temperature....if you wish to have a warm room. Heat is lost through the wall. Cement can dampen vibrations.

- Q: construction, cement, concrete

- In the US, the predominate method for testing concrete strength is ASTM C31 and C94. C94 provides the general procedures necessary as C31 provides field methods. Generally speaking, concrete strength is directly related to water / cement ratios. The less water in the mix, the greater the strength. However, more water makes the concrete easier to place and finish. Superplasticizers are admixtures that improve concrete workability without adding water. There are also a variety of materials that can be added to concrete to increase strength in addition to a low water/cement ratio (0.35 or less). The number and explanation behind those materials and methods are beyond the scope of what can be covered here. But let it be understood the standard 3000psi concrete can be formulated to provide compressive strengths of 6000psi and more.

- Q: When installing cement backer board, is it necessary to put down some thin set mortar and then lay the board and screw in place, or can I do without the thin set?

- Backerboard is used to stiffen the wood subfloor when you lay tile. This is important so the subfloor doesn't deflect when additional weight is put onto it (thus, breaking the tiles). Since you have a cement floor, putting down a backerboard wouldn't make any sense, but the floor does need to be level. You can pick up self-leveling compound at the hardware store. It's going to be in the same aisle as grouts, tools, etc.

- Q: Poll: Rubber cement or School glue?

- School glue. I hate the way rubber cement smells, but I have to use it often for art projects or when I'm working on the set for my school play.

1. Manufacturer Overview

| Location | Rizhao, Shandong, China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America; South America; Southeast Asia; Africa; Mid East |

| Company Certifications | Certificate of Quality; certificate for products exemption from quality surveillance inspecction; ISO9001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Rizhao port |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese, French, Russian |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

4A Molecular Sieve with Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton m.t.

- Supply Capability:

- 10000 Metric Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords