430 Mirror finishing Stainless Steel Sheet made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. | Item | Stainless steel sheets / stainless steel plates | ||

2. | Standard | ASTM,AISI,GB,JIS,SUS,EN,DIN,etc. | ||

3. |

Material | 200 series | 300 series | 400 series |

201,202 | 300,301,304,304L,309S,310S,316Ti,316L, 317L,321,329,329LA,329LD | 409,410,430,430LX,600,601 | ||

4. |

Specification | Thickness | 0.3mm-20mm | |

Width | 1000/1200/1219/1220/1250/1500/1800mm | |||

Length | 2000/2500/3000/6000mm | |||

5. | Surface finished |

2B/BA/HAIRLINE/8K/NO.1/NO.4 | ||

6. | Techinque | Cold rolled/ hot rolled | ||

7. |

Application | Stainless steel sheets are widely used in below fields:

1:Chemical industry equipment,industrial tanks 2:Medical instruments,tableware,kitchen utensil,kitchen ware. 3:Architectural purpose,milk or food processing facilities. 4:Hospital equipment,interior exterior decoration for building 5:Architectural purposes,escalators,kitchen ware,vehicles.

Or they can be made as your requirement. | ||

8. | Package | Standard export package. | ||

9. | Market | Asia,Africa,Europe,Middle East,South and North America,Oceania,etc | ||

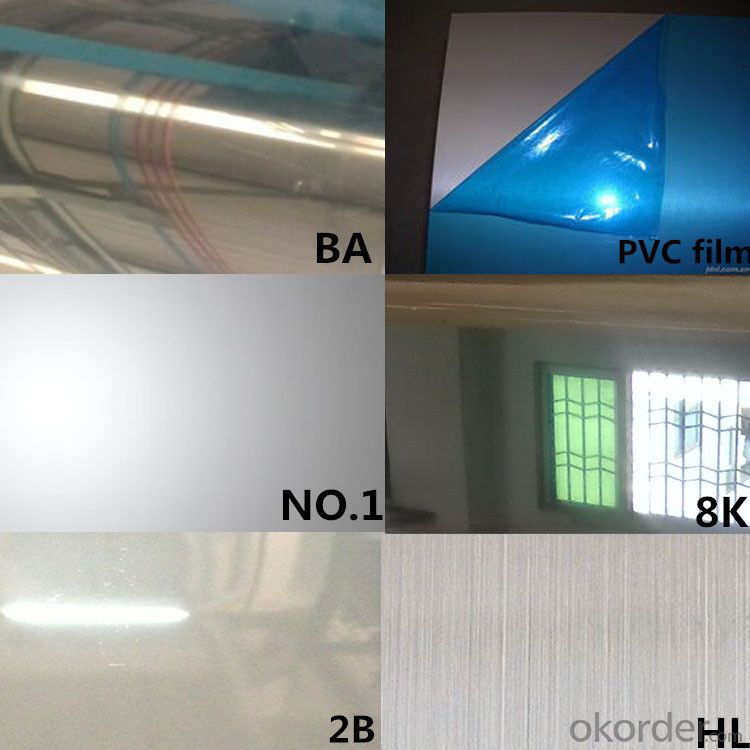

Surface finished | Definition &Application | |

2B | Those finished,after cold rolling, by heat treatment,picking or other equivalent treatment and lastly by cold rolling to given appropriate luster | Medical equipment, construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling | Kitchen utensils, Electric equipment, Building construction. |

No.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001 | Kitchen utensils, Building construction. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building construction |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling | Chemical tank pipe |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. | |

Packaging & Shipping

Packing details | 5000 Ton/Tons per Month |

Delivery Time | 7-15 working days |

Payment Terms | L/C ,T/T , western union , paypal , alipay |

Shipping | By container |

Our Services

1) offer free samples

2) welcome to visit our factory

3) make logo on the surface of the product according to customer's demand

4) all enquiries will be treated carefully and be replied soon

- Q: Are stainless steel sheets suitable for structural applications?

- Yes, stainless steel sheets are suitable for structural applications. Stainless steel has excellent strength, durability, and corrosion resistance properties, making it a reliable choice for various structural projects. It can withstand high loads and extreme weather conditions, making it suitable for applications such as bridges, buildings, and infrastructure projects.

- Q: How do you attach stainless steel sheets to a wall?

- To attach stainless steel sheets to a wall, you can use a combination of adhesive and mechanical fasteners. First, ensure that the wall is clean and free from any debris or grease. Apply a strong construction adhesive to the back of the stainless steel sheet, spreading it evenly across the surface. Then, press the sheet firmly against the wall and hold it in place for a few minutes to allow the adhesive to bond. Additionally, use mechanical fasteners such as screws or nails to secure the stainless steel sheet to the wall, placing them along the edges and in the center of the sheet for added support and stability.

- Q: Can stainless steel sheets be used for architectural cladding?

- Yes, stainless steel sheets can be used for architectural cladding. Stainless steel is a versatile material that offers a range of benefits for architectural applications. It is highly resistant to corrosion, making it suitable for both interior and exterior cladding in various environments. Stainless steel sheets are also durable and require minimal maintenance, which is advantageous for long-term use in architectural projects. Additionally, stainless steel has an attractive appearance and can be finished in different ways, allowing architects to achieve the desired aesthetic for their designs. Its strength and fire resistance properties further enhance its suitability for architectural cladding. Overall, stainless steel sheets are a popular choice for architectural cladding due to their durability, corrosion resistance, aesthetic appeal, and versatility.

- Q: What is the difference between hot rolled and cold rolled stainless steel sheets?

- The main difference between hot rolled and cold rolled stainless steel sheets lies in the manufacturing process. Hot rolled stainless steel sheets are produced by heating a stainless steel slab above its recrystallization temperature and then rolling it through a series of rollers to achieve the desired thickness. This process results in a rougher surface finish and can sometimes lead to a slight curvature in the sheets. On the other hand, cold rolled stainless steel sheets are manufactured by cooling the hot rolled sheets and then passing them through a set of rollers at room temperature. This process creates sheets with a smoother surface finish and precise dimensions. Cold rolling also increases the strength and hardness of the stainless steel. In summary, hot rolled stainless steel sheets have a rougher surface finish and may exhibit slight curvatures, while cold rolled stainless steel sheets have a smoother surface finish and are more precise in their dimensions.

- Q: How do I clean and maintain stainless steel sheets?

- To clean and maintain stainless steel sheets, follow these simple steps: 1. Start by removing any loose dirt or debris from the surface using a soft cloth or sponge dampened with warm water. 2. For tougher stains or fingerprints, mix a mild detergent with warm water and apply it to the sheet using a non-abrasive sponge or cloth. Gently scrub the affected area in the direction of the grain. 3. Rinse the sheet thoroughly with clean water to remove any residue from the detergent. 4. Dry the stainless steel sheet with a soft cloth to prevent water spots or streaks from forming. 5. To maintain the shine and protect against future stains, apply a small amount of stainless steel cleaner or polish to a clean, soft cloth. Rub the surface in the direction of the grain, avoiding circular motions. 6. Wipe off any excess cleaner or polish with a separate clean cloth to ensure an even finish. 7. For stubborn stains or scratches, you can use a stainless steel cleaner that contains mild abrasives. However, be cautious as these products may scratch the surface if used improperly. 8. Avoid using abrasive sponges, steel wool, or harsh chemicals as they can damage the stainless steel surface. 9. Regularly dust the stainless steel sheets with a soft cloth to prevent the accumulation of dirt or dust particles. 10. Lastly, remember to always refer to the manufacturer's instructions for specific cleaning and maintenance recommendations for your particular stainless steel sheet product.

- Q: How do you prevent staining or discoloration on stainless steel sheets in coastal environments?

- To prevent staining or discoloration on stainless steel sheets in coastal environments, it is essential to regularly clean and maintain the surface. This can be done by using mild detergents or stainless steel cleaners to remove any salt, dirt, or other contaminants. Additionally, applying a protective coating or a high-quality wax can help to create a barrier against the corrosive effects of salty air and moisture. Regular inspections and prompt removal of any signs of corrosion or staining are also vital to prevent further damage.

- Q: What are the different types of colored finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of colored finishes that serve to enhance their appearance and offer different aesthetic options. Some of the most popular colored finishes include: 1. Mirror Finish: This particular finish achieves a highly reflective, mirror-like surface on the stainless steel sheets. By polishing the stainless steel surface to a high gloss, a sleek and modern look is achieved. Mirror finishes are commonly used for decorative purposes. 2. Satin Finish: Also known as a brushed or matte finish, this type of finish provides a smooth, non-reflective surface. It is achieved by brushing the stainless steel surface with an abrasive material. Satin finishes are commonly used in architectural and industrial applications, giving off a clean and contemporary appearance. 3. Colored Powder Coating: This finish involves applying a dry powder to the stainless steel surface and then curing it under heat. The result is a durable and uniform colored finish. Colored powder coatings offer a wide range of hues, allowing for customization and versatility in design. 4. PVD Coating: The process of Physical Vapor Deposition (PVD) entails depositing a thin layer of metal onto the stainless steel surface. This coating can be in various colors, such as gold, bronze, black, or rose gold. PVD coatings are highly durable and resistant to wear, making them suitable for high-traffic areas or decorative applications. 5. Colored Anodizing: This finish is achieved through an electrochemical process that creates a protective oxide layer on the stainless steel surface. By incorporating dyes into the anodizing process, a plethora of colors can be achieved. Colored anodized finishes are known for their corrosion resistance and find utility in architectural or design-oriented applications. Each of these colored finishes possesses unique characteristics and can be selected based on desired aesthetics, durability, and specific application requirements. It is crucial to consider factors such as maintenance requirements, environmental conditions, and intended use when choosing a colored finish for stainless steel sheets.

- Q: What are the different shapes available for stainless steel sheets?

- Stainless steel sheets come in various shapes to meet specific requirements and applications. Let's explore some of the most common options: 1. Rectangular sheets: These sheets are widely used and can be easily cut to the desired dimensions. They are available in different standard sizes. 2. Round sheets: Round stainless steel sheets are ideal for decorative purposes or when a seamless or curved surface is desired. They come in various diameters and thicknesses. 3. Square sheets: Similar to rectangular sheets, square stainless steel sheets are versatile and provide a symmetrical and uniform appearance. They can be easily customized to fit specific sizes. 4. Perforated sheets: These sheets have a regular pattern of small holes punched through them. They are commonly used in architectural and industrial applications that require ventilation, filtration, or visibility. 5. Embossed sheets: These sheets feature raised or recessed patterns on their surface, adding texture and visual interest. They find applications in interior design, furniture manufacturing, and automotive industries. 6. Expanded metal sheets: These sheets are created by cutting and stretching a solid stainless steel sheet, resulting in a grid-like pattern with diamond-shaped openings. They are commonly used in security fencing, walkways, and industrial settings. 7. Checker plate sheets: Also known as tread plate or diamond plate, these sheets have a raised diamond pattern on the surface. They are frequently used for slip-resistant flooring, stair treads, and decorative accents. These examples represent just a few of the available stainless steel sheet shapes. The choice of shape depends on the specific requirements, aesthetic preferences, and functional needs of the project.

- Q: What are the different types of finishes available for stainless steel sheets?

- There are several different types of finishes available for stainless steel sheets, each offering its own unique appearance and level of protection. Some of the most common finishes include: 1. No. 1 Finish: This is a dull, rough, and non-reflective finish that is achieved by hot rolling the stainless steel sheet. It is commonly used for industrial applications where appearance is not a primary concern. 2. No. 2B Finish: This finish is a smooth, reflective surface achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. It is widely used in applications that require a visually appealing finish, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this is achieved by applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is commonly used for architectural and decorative purposes. 4. No. 8 Finish: This is a highly reflective finish that is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is often used in applications where a sleek and sophisticated look is desired, such as in high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is achieved by annealing the stainless steel sheet in a controlled atmosphere and then pickling or blasting it to remove any oxide scale. It results in a smooth, bright surface that is commonly used in applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: This finish is achieved by mechanically brushing the surface of the stainless steel sheet with fine abrasive belts. It creates a subtle, textured look that can be used for architectural and decorative purposes. 7. Embossed Finish: This finish involves imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is often used in applications such as elevator interiors, wall cladding, and signage. These are just a few of the many finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The choice of finish depends on the specific application and desired appearance.

- Q: Are stainless steel sheets suitable for food packaging equipment?

- Food packaging equipment can greatly benefit from the use of stainless steel sheets. The food industry favors stainless steel because of its many advantageous features. First and foremost, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, smell, or appearance. As a result, it is safe for direct contact with food products. Furthermore, stainless steel is resistant to corrosion, rust, and staining, ensuring the equipment's durability and longevity. Cleaning and sanitizing stainless steel is also a breeze, making it perfect for maintaining the high levels of hygiene required in food packaging processes. The smooth surface of stainless steel sheets minimizes the risk of bacterial growth and simplifies the cleaning process even further. Moreover, stainless steel possesses excellent strength and heat resistance properties, allowing it to withstand high temperatures without losing its shape or structural integrity. This is especially crucial in food packaging equipment that involves heat sealing or thermal processing. To sum up, stainless steel sheets are an excellent choice for food packaging equipment due to their non-reactive nature, resistance to corrosion, ease of cleaning, and high strength. These qualities ensure both the safety and quality of food products during packaging processes, making stainless steel a reliable and hygienic option.

Send your message to us

430 Mirror finishing Stainless Steel Sheet made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords