4'X10' Aluminum Sheets for Color Coated Wall Decoration AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Coils for Color Coated with Wall Decoration AA3003

Aluminium Coils for Color Coated with Wall Decoration AA3003 is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Color Coated with Wall Decoration AA3003

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

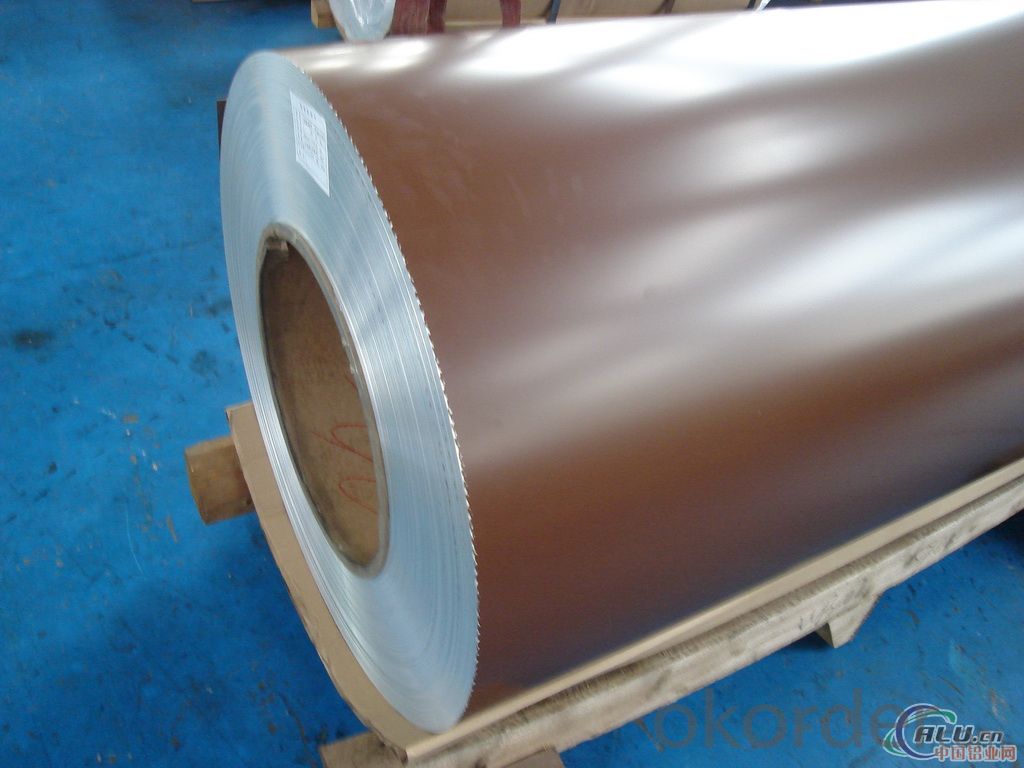

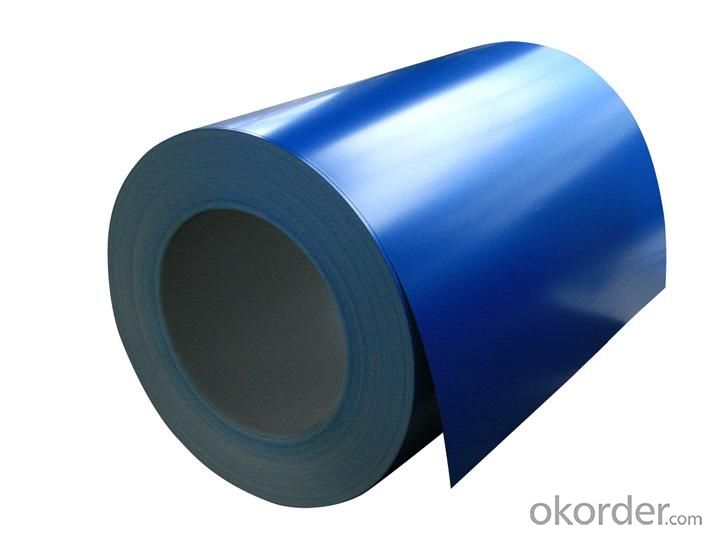

3. Image of Aluminium Coils for Color Coated with Wall Decoration AA3003

4. Product Specification of Aluminium Coils for Color Coated with Wall Decoration AA3003

| Alloy | Temper | Style | Thickness | Width |

| AA1100 | H14 | Direct Casting | 0.2mm-3mm | 1000mm-1500mm |

5.FAQ of Aluminium Coils for Color Coated with Wall Decoration AA3003

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Is it possible to utilize recycled aluminum to manufacture new items?

- <p>Yes, recycled aluminum can be used to create new products. Aluminum is highly recyclable, and the process of recycling it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains the same properties as new aluminum, making it suitable for a wide range of applications, from packaging to construction materials. The use of recycled aluminum helps reduce waste, conserve resources, and lower environmental impact.</p>

- Q: Normally, when I install a 30-amp dryer receptacle, the wire is #10 copper and I double over the end with lineman's pliers prior to landing it in the lug just to be extra tight. Today I replaced a dryer outlet wired with #8 aluminum SE. The quandaray I have is that the lugs seem made for #6 and the #8 just sort of flattens and divides under the screw. Is this safe? The doubling over move makes the wire way too thick for the lugs to close. I've been doing electric for many years and have never run into this. Should I go back and re-run the circuit (only about 30 feet) in #10 copper? What is the actual draw of a typical electric dryer on high heat, anyway? Thanks.

- Copper safer than Alum at high amperages

- Q: What specific conditions or regulations must be met when using aluminum sheets in commercial construction?

- <p>Yes, there are special requirements for using aluminum sheets in commercial buildings. These include adherence to building codes and standards for fire resistance, structural integrity, and weather resistance. Aluminum sheets must meet specific thickness and strength requirements depending on the application. They also need to comply with environmental regulations regarding sustainability and recyclability. Additionally, for aesthetic purposes, the finish and color of the aluminum sheets should be in line with architectural design guidelines. It's crucial to consult with architects, engineers, and local building authorities to ensure all requirements are met.</p>

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- Chemical transfer piping cannot rely on 101 aluminum sheets as they are unsuitable. The reactivity and corrosion propensity of aluminum make it generally unfit for handling specific chemicals. Industries like aerospace or construction prefer aluminum due to its lightweight nature and excellent thermal conductivity. However, for chemical transfer piping, it is wiser to opt for materials that possess corrosion resistance and can endure the specific chemicals being transported. Stainless steel, PVC, or high-density polyethylene (HDPE) are recommended alternatives.

- Q: Can aluminum sheets be used for architectural applications?

- Yes, aluminum sheets can be used for architectural applications. Aluminum is a versatile and lightweight material that offers excellent strength, durability, and corrosion resistance. It can be easily formed, shaped, and fabricated into various architectural elements such as façades, roofs, windows, doors, and cladding. Its aesthetic appeal, along with its ability to withstand harsh weather conditions, makes it a popular choice in contemporary architectural designs.

- Q: Solid aluminum or solid wooden boxes-no glass top. Would glass make the temperature rise more quickly? (ie Solar)? Thanks.Joseph

- If all of the heat transfer is from the sun through the open top, a wooden box would keep the heat in, acting as an insulator. The aluminum box would quickly radiate away any trapped heat. If the heat is coming in through the walls, then aluminum would conduct the heat better. A glass top would definitely allow the sun's energy in while trapping the heat. That is how a greenhouse works! The aluminum vs. wood discussion still holds, wood is better in this situation.

- Q: Can aluminum sheet be used for aerospace applications?

- Yes, aluminum sheet can be used for aerospace applications. Aluminum is a widely used material in the aerospace industry due to its desirable properties such as lightweight, high strength, and corrosion resistance. It is commonly used in the construction of aircraft fuselages, wings, and structural components. Aluminum sheets are often used in the fabrication of aircraft panels, where their high strength-to-weight ratio allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum sheets can be easily formed, machined, and welded, making them versatile and suitable for various aerospace applications.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated.

- Q: It seemed in my experiment that aluminum wasn't reactive at all in the displacement reactions, except with copper sulfate. Is there a reason? or did I make a mistake? aluminum is more reactive than e.g silver nitrate, why didn't it react with it?

- Aluminium has a protective coating of Aluminium Oxide, this prevents many chemicals reaching the surface. This is because aluminium has a very strong affinity for oxygen and bonds to it with extremely strong bonds. It can be removed by dipping it carefully into a solution of Mercury (II) Chloride.

Send your message to us

4'X10' Aluminum Sheets for Color Coated Wall Decoration AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords