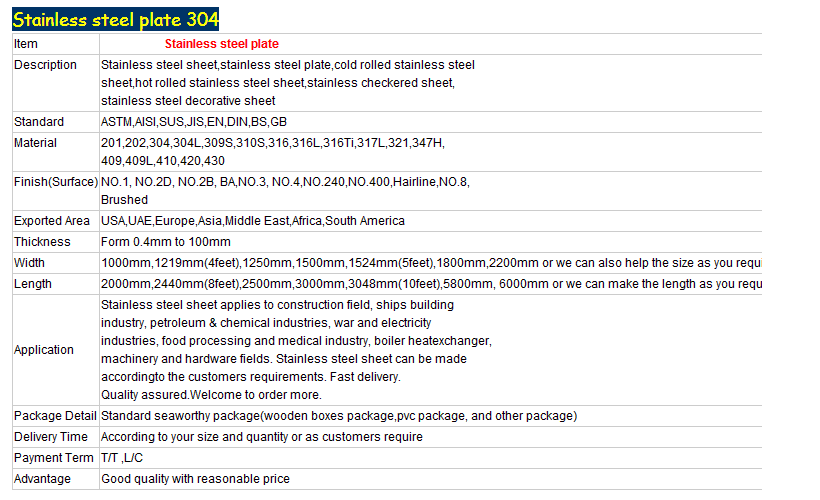

316 Made in china Tisco 304 stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are stainless steel pipes suitable for wastewater treatment plants?

- Yes, stainless steel pipes are suitable for wastewater treatment plants. Stainless steel is known for its excellent corrosion resistance, which is crucial in an environment where wastewater can contain aggressive chemicals and substances. Stainless steel pipes can withstand the high temperatures and pressures often encountered in wastewater treatment plants, making them a durable and reliable choice. Additionally, stainless steel pipes are easy to clean and maintain, reducing the risk of contamination in the treatment process. Therefore, stainless steel pipes are a popular choice for wastewater treatment plants due to their durability, corrosion resistance, and ease of maintenance.

- Q: Can stainless steel pipes be insulated with polycaprolactone?

- Stainless steel pipes can indeed be insulated with polycaprolactone. Polycaprolactone, also known as PCL, is a thermoplastic polymer that has excellent thermal insulation properties. It has a low thermal conductivity, which makes it an effective choice for insulating pipes and preventing heat loss or gain. Additionally, PCL is also resistant to moisture and chemicals, making it suitable for various environments and applications. When applied as insulation on stainless steel pipes, polycaprolactone can help maintain the desired temperature, reduce energy consumption, and prevent condensation.

- Q: How do you insulate stainless steel pipes?

- To prevent heat loss, condensation, and energy wastage, insulating stainless steel pipes is a crucial step. There are multiple effective methods available for insulating these pipes: 1. Pipe insulation wraps: The most common and cost-effective method involves using wraps made of materials like fiberglass, rubber, or foam. These wraps are easy to install and provide excellent insulation against heat transfer. They also serve as a barrier to prevent condensation. 2. Insulation jackets: Pre-formed covers made of insulation materials such as mineral wool or fiberglass are used for this method. These jackets are designed to fit around the stainless steel pipes and are secured with adhesive or straps. They offer a high level of thermal insulation and are ideal for pipes in areas with extreme temperatures. 3. Spray foam insulation: This method entails spraying a layer of polyurethane foam insulation directly onto the stainless steel pipes. This creates a seamless and durable insulation layer that adheres well to the pipes, providing excellent thermal insulation and preventing moisture buildup. 4. Insulation tape: Foam or rubber insulation tape is wrapped around the stainless steel pipes to provide thermal insulation. This method works best for smaller pipes or areas with limited space. Regardless of the chosen method, it is important to consider the temperature range, moisture exposure, and specific requirements of the stainless steel pipes when selecting insulation materials. Additionally, proper installation and maintenance of the insulation are essential to optimize its effectiveness and durability.

- Q: Can stainless steel pipes be painted?

- Yes, stainless steel pipes can be painted. However, it is important to note that stainless steel is a non-porous material and has a smooth surface, which can make it challenging for paint to adhere to it effectively. To ensure proper adhesion, it is recommended to clean the surface thoroughly and apply a primer specifically designed for stainless steel. This will help create a rougher texture on the surface, allowing the paint to bond better. Additionally, using a high-quality, durable paint that is suitable for metal surfaces will enhance the longevity of the painted finish.

- Q: What is the cost difference between stainless steel pipes and other materials?

- The cost difference between stainless steel pipes and other materials can vary depending on various factors such as the type of material being compared, the size and specifications of the pipes, and the current market conditions. In general, stainless steel pipes tend to be more expensive than other materials such as PVC, copper, or galvanized steel. This is primarily due to the higher production and raw material costs associated with stainless steel, as well as its superior qualities and durability. Stainless steel pipes offer numerous advantages over other materials, including excellent corrosion resistance, high strength, and the ability to withstand extreme temperatures. These qualities make stainless steel pipes ideal for various applications, especially in industries such as oil and gas, chemical processing, and water treatment. While stainless steel pipes may have a higher upfront cost, they often provide long-term cost savings due to their extended lifespan and reduced maintenance requirements. Additionally, the higher initial investment in stainless steel pipes can be justified by considering the potential costs associated with pipe failures, leaks, or replacements that may occur with other materials. It is important to note that the cost difference between stainless steel pipes and other materials can vary significantly depending on the specific project requirements and market conditions. Therefore, it is advisable to consult with suppliers, contractors, or industry professionals to obtain accurate and up-to-date pricing information for a specific application.

- Q: How do you prevent stress corrosion cracking in stainless steel pipes?

- To prevent stress corrosion cracking in stainless steel pipes, several precautions can be taken: 1. Material selection: Choose a stainless steel grade that is resistant to stress corrosion cracking. Austenitic stainless steel grades such as 304 and 316 are commonly used due to their high resistance to corrosion and cracking. 2. Proper fabrication and welding: Ensure that the welding procedures used during fabrication are suitable for stainless steel and minimize the introduction of residual stresses. This includes using proper welding techniques, maintaining appropriate heat input, and employing post-weld heat treatment if necessary. 3. Avoid exposure to corrosive environments: Protect stainless steel pipes from exposure to aggressive chemicals, high chloride concentrations, and other corrosive substances. Regularly inspect the environment and take necessary measures to prevent contact between the pipes and corrosive agents. 4. Control operating conditions: Avoid subjecting stainless steel pipes to excessive tensile stresses or temperatures that can promote stress corrosion cracking. This can be achieved by maintaining proper operating conditions, such as controlling pressure, temperature, and flow rates within the recommended limits. 5. Regular inspection and maintenance: Conduct regular inspections to identify any signs of stress corrosion cracking. This may include visual inspections, non-destructive testing techniques (e.g., ultrasonic testing), or corrosion monitoring. If any signs of stress corrosion cracking are detected, immediate action should be taken to repair or replace the affected pipe sections. 6. Proper cleaning and maintenance: Keep stainless steel pipes clean and free from contaminants that can accelerate corrosion. Regular cleaning and maintenance practices should be followed, including removing any deposits or foreign materials that may promote stress corrosion cracking. Overall, preventing stress corrosion cracking in stainless steel pipes requires a combination of proper material selection, fabrication techniques, environmental control, regular inspections, and appropriate maintenance practices. By implementing these measures, the risk of stress corrosion cracking can be significantly reduced, ensuring the longevity and reliability of stainless steel pipes.

- Q: Can stainless steel pipes be bent or curved?

- Yes, stainless steel pipes can be bent or curved.

- Q: Are stainless steel pipes suitable for drinking water applications?

- Yes, stainless steel pipes are suitable for drinking water applications. Stainless steel is a highly durable and corrosion-resistant material, making it an excellent choice for transporting drinking water. It does not leach harmful substances into the water and is resistant to rust and scaling, ensuring the water remains clean and safe for consumption. Additionally, stainless steel pipes are easy to clean and maintain, which further promotes the hygiene of the water supply. The long lifespan and reliability of stainless steel pipes also make them a cost-effective solution for drinking water applications.

- Q: What is the maximum diameter of stainless steel pipes available?

- The maximum diameter of stainless steel pipes available can vary depending on the manufacturer and supplier. However, stainless steel pipes typically range from smaller diameters, such as ½ inch or 1 inch, to larger diameters, such as 36 inches or even more. It is important to note that the availability of larger diameters may be limited and may require special ordering or customization. Therefore, it is advisable to consult with specific manufacturers or suppliers to determine the maximum diameter of stainless steel pipes they offer.

- Q: What is the difference between 201 and 316 stainless steel pipes?

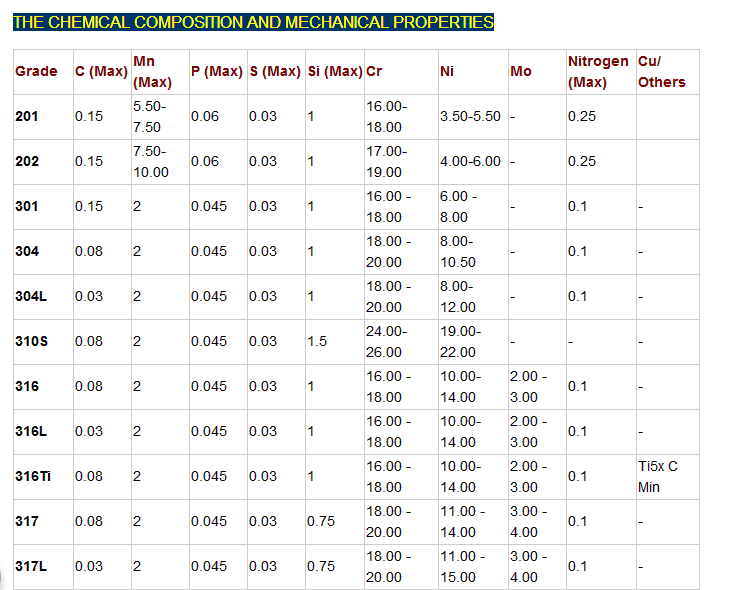

- The main difference between 201 and 316 stainless steel pipes lies in their chemical composition and respective properties. 201 stainless steel is a lower grade of stainless steel compared to 316. It contains a higher amount of manganese and nitrogen, which gives it improved strength and corrosion resistance compared to other lower grade stainless steels. However, it is not as durable as 316 stainless steel and is more prone to corrosion and rusting. On the other hand, 316 stainless steel is a high-quality grade that contains a higher percentage of chromium and nickel. These elements enhance its corrosion resistance, making it highly resistant to pitting and crevice corrosion, especially in chloride environments. 316 stainless steel pipes are also more resistant to high temperatures and have superior strength compared to 201 stainless steel pipes. Therefore, 316 stainless steel pipes are widely used in industries with demanding requirements such as marine, chemical, and medical sectors, where corrosion resistance and durability are crucial. 201 stainless steel pipes, while suitable for general applications, are more commonly used in less demanding environments where cost-effectiveness is a priority.

Send your message to us

316 Made in china Tisco 304 stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords