304 stainless steel sheet suppliers china

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 25000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304 stainless steel sheet suppliers china

1.Product Description

1. Specifications about stainless steel sheet

Commodity430 304 304L 316L 201 316 4x8 sheet metal prices stainless steel

Grade201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L

BrandTISCO ,BAOSTEEL,POSCO,JISCO,LISCO

CertificationSGS,BV,IQI,TUV,ISO,etc

Thickness0.2mm-150mm

Width1000,1219,1250,1500mm, or as your requirements

Length2000,2438,2500,3000,6000mm, or as your requirements

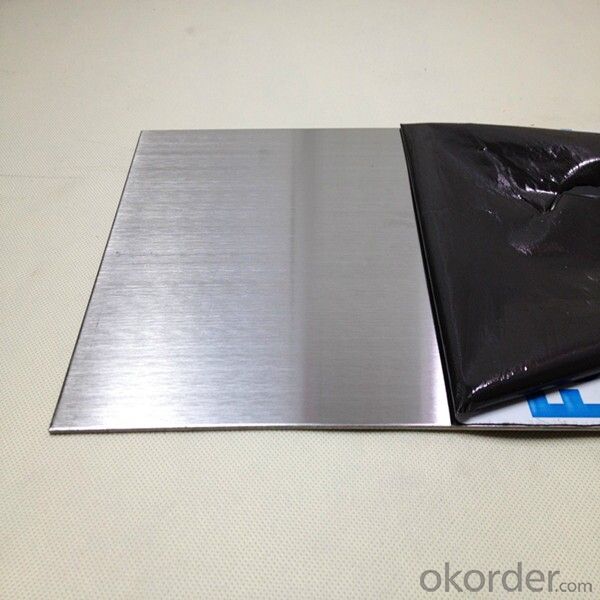

SurfaceNo.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film.

StandardASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc

Delivery time5-7 days after confirming the order

MOQ1 Ton

AdvantagesShowing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste.

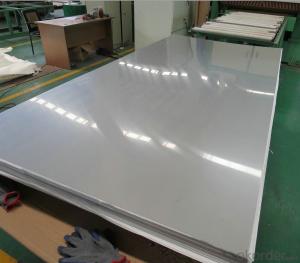

2.Products photos

3.FAQ

1.Small quantity, short time delivery

If we have stocks, the delivery time is less than 7 days,If the quantity is more than 500Tons,the delivery time is abou 30 days after confirming the order.

2.Choose the appropriate metals stainless steel for your needs.

We carefully balance quality, delivery time and price,procure various grades metals from all over the world.

3.Lower total cost

We taking your processing into account,offer you reduce a total cost by using our product.

We assure you:

Small MOQ + Cheap Price + Fantastic Quality + Fast Delivery

- Q: Can stainless steel sheets be used for power generation equipment?

- Yes, stainless steel sheets can be used for power generation equipment. Stainless steel is a versatile material that offers several beneficial properties for power generation applications. It has excellent corrosion resistance, which is crucial in environments where the equipment is exposed to water, steam, or other corrosive substances. Stainless steel also has high strength and durability, making it suitable for withstanding the high temperatures and pressures typically found in power generation systems. Additionally, stainless steel is a good conductor of electricity, making it suitable for electrical components and connections within the equipment. Therefore, stainless steel sheets are commonly used in the construction of power generation equipment such as turbines, boilers, heat exchangers, and exhaust systems.

- Q: What are the different types of stainless steel sheets?

- There are several different types of stainless steel sheets available, each with its own unique properties and uses. Some of the most common types include: 1. Austenitic stainless steel sheets: This is the most widely used type of stainless steel, known for its excellent corrosion resistance and high ductility. It is non-magnetic and can be easily formed, making it suitable for various applications such as kitchen equipment, architectural structures, and automotive components. 2. Ferritic stainless steel sheets: This type of stainless steel has a lower chromium content compared to austenitic stainless steel. It possesses good corrosion resistance in certain environments and is often used in applications that require high temperature resistance, such as industrial ovens and exhaust systems. 3. Martensitic stainless steel sheets: Martensitic stainless steel is known for its high strength and hardness. It is magnetic and offers good corrosion resistance, making it suitable for applications that require both strength and corrosion resistance, such as knives, turbine blades, and valve parts. 4. Duplex stainless steel sheets: This type of stainless steel combines the properties of both austenitic and ferritic stainless steels. It has excellent corrosion resistance, high strength, and good weldability. Duplex stainless steel is commonly used in industries such as chemical processing, oil and gas, and marine environments. 5. Precipitation-hardening stainless steel sheets: This type of stainless steel is heat treatable, offering high strength and excellent corrosion resistance. It is commonly used in applications that require high strength-to-weight ratio, such as aerospace components, springs, and shafts. These are just a few examples of the different types of stainless steel sheets available. The choice of which type to use depends on the specific requirements of the application, including factors such as corrosion resistance, strength, formability, and cost.

- Q: Are stainless steel sheets resistant to galvanic corrosion?

- Yes, stainless steel sheets are resistant to galvanic corrosion. Galvanic corrosion occurs when two dissimilar metals come into contact in the presence of an electrolyte, such as moisture or saltwater. In such cases, one metal acts as an anode and the other as a cathode, leading to the transfer of electrons and the corrosion of the anode. Stainless steel is an alloy that contains chromium, which forms a passive oxide layer on its surface. This oxide layer acts as a protective barrier, preventing the transfer of electrons and thus effectively resisting galvanic corrosion. The chromium in stainless steel reacts with oxygen in the air to create a thin, invisible, and self-repairing layer of chromium oxide. This layer provides excellent corrosion resistance and makes stainless steel highly resistant to galvanic corrosion when in contact with other metals. However, it is important to note that the level of corrosion resistance may vary depending on the specific grade and composition of stainless steel used. Some stainless steel alloys, such as Type 316 stainless steel, offer even higher resistance to galvanic corrosion due to the addition of molybdenum, which enhances its corrosion resistance in aggressive environments. In summary, stainless steel sheets are generally highly resistant to galvanic corrosion due to the presence of a passive chromium oxide layer on their surface. This makes stainless steel a reliable choice for applications where galvanic corrosion is a concern, such as in marine environments or when in contact with dissimilar metals.

- Q: What are the different types of etched finishes available for stainless steel sheets?

- Stainless steel sheets come in a range of etched finishes, each with its own unique and distinctive look. Let's explore some of the most common options: 1. Brushed Finish: A popular choice, this etched finish involves using a fine abrasive material to create a smooth and satin-like texture on the surface of the stainless steel sheet. 2. Bead Blasted Finish: For a matte and slightly rough appearance, small glass or ceramic beads are blasted onto the sheet at high pressure, resulting in a non-directional and uniform texture. 3. Mirror Finish: Also known as a No. 8 finish, this etched option gives the stainless steel sheet a flawless and shiny appearance. It involves a series of grinding, buffing, and polishing processes to create a highly reflective and mirror-like surface. 4. Satin Finish: Similar to the brushed finish but with a finer texture, this etched option uses a finer abrasive material during the brushing process, resulting in a soft and elegant appearance. 5. Patterned Finish: This etched finish allows for creative and customizable options, as it involves creating various patterns or designs on the sheet's surface. Techniques such as laser etching, chemical etching, or embossing can be used to achieve this effect. These different etched finishes offer a wide range of aesthetic choices for stainless steel sheets, making them suitable for various architectural, decorative, and industrial applications. The choice of finish depends on the desired appearance, functionality, and intended use of the sheet.

- Q: How do stainless steel sheets resist corrosion?

- Due to its unique composition and the presence of a protective oxide layer, stainless steel sheets have the ability to resist corrosion. Stainless steel is comprised of iron, chromium, and other alloying elements like nickel and molybdenum. Chromium is particularly essential for the corrosion resistance of stainless steel. When exposed to oxygen, chromium creates a thin and invisible oxide layer on the surface of the stainless steel, which is referred to as the passive layer. This passive layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and safeguarding it against corrosion. This layer is the reason why stainless steel is called "stainless," as it remains free from rust and corrosion. The chromium oxide layer has the ability to self-repair and reform if it gets damaged or scratched, ensuring continuous protection for the stainless steel. This characteristic enables stainless steel sheets to be utilized in various environments, including those with high humidity, exposure to chemicals, and even saltwater. Furthermore, alloying elements such as nickel and molybdenum enhance the corrosion resistance of stainless steel. Nickel enhances the stability and strength of the passive layer, while molybdenum improves resistance against pitting and crevice corrosion. Moreover, surface finishes like polishing or passivation can provide additional protection against corrosion for stainless steel sheets. These processes eliminate any contaminants or impurities from the surface and promote the formation of a stronger and more uniform passive layer. In conclusion, the combination of chromium, other alloying elements, and the protective oxide layer makes stainless steel sheets extremely resistant to corrosion, ensuring durability and longevity in a wide range of applications.

- Q: Can stainless steel sheets be used for staircase railings?

- Yes, stainless steel sheets can be used for staircase railings. Stainless steel is a popular choice for staircase railings due to its durability, strength, and resistance to corrosion. Stainless steel sheets can be cut, shaped, and welded to create a variety of railing designs and styles. They can also be finished in different ways, such as brushed or polished, to achieve the desired aesthetic appearance. Stainless steel railings are not only aesthetically pleasing but also provide a safe and sturdy support for staircases.

- Q: Can stainless steel sheets be used for kitchen backsplashes?

- Yes, stainless steel sheets can be used for kitchen backsplashes. Stainless steel is a popular choice for backsplashes due to its durability, resistance to stains and heat, and easy maintenance. It provides a sleek and modern look to the kitchen while also protecting the walls from splatters and spills.

- Q: What are the different types of stainless steel sheet finishes for industrial applications?

- There are several types of stainless steel sheet finishes for industrial applications, including 2B, No. 4, No. 8, BA, and brushed finishes.

- Q: What is the maximum thickness available for stainless steel sheets?

- The maximum thickness available for stainless steel sheets can vary depending on the specific grade of stainless steel and the manufacturing capabilities of the supplier. However, in general, stainless steel sheets can be found in thicknesses ranging from 0.5mm to 80mm. It is important to note that thicker sheets are typically used for specialized applications that require increased strength and durability, such as construction projects or heavy machinery. When selecting stainless steel sheets, it is crucial to consider the intended use and consult with a reputable supplier to ensure that the desired thickness is available.

- Q: What are the different types of embossed finishes available for stainless steel sheets?

- There are several types of embossed finishes available for stainless steel sheets, including diamond, quilted, linen, and leather grain patterns. Each finish offers a unique texture and aesthetic appeal, allowing for various design options in different applications.

Send your message to us

304 stainless steel sheet suppliers china

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 25000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords