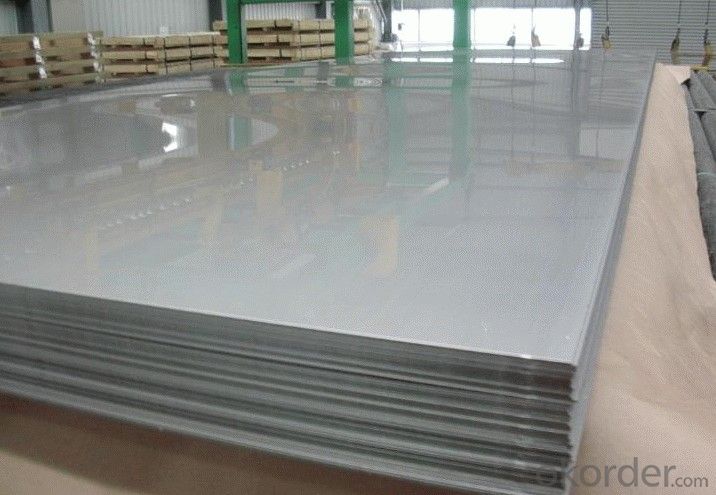

304 Stainless Steel Sheet ,Deep Drawing Board ,Wire Drawing Board ,Mirror Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

304 stainless steel wire drawing board is stainless steel surface like silk texture, this is just a kind of stainless steel processing technology. The surface is matte, carefully see there is a trace of texture, but can not touch. Than the general bright surface of stainless steel wear, looks more grade.The mirror panel, polishing liquid and polishing equipment through polishing on stainless steel surface, the surface was like a mirror clear. Uses: mainly used in building decoration, decoration, decoration, elevator industrial facilities decoration and other stainless steel products.

Produced by cold-rolled plate, flatness flatness, uniform color, good tensile ability. Ordinary ST12 grade products, its elongation rate of up to 38%, higher than the other similar products around 33%. So the product of the iron and steel can be competent for bending 180 degrees, general tension and other mechanical processing requirements. For electrical cabinet, ordinary tensile hardware, steel pipe, small pumps, auto parts etc.. Special needs to be emphasized is that of AISC Cold rolled plate of Kaiping, Guangdong VCD, DVD power amplifier manufacturer specified materials, VCD, DVD power amplifier housing requirements on the surface of the steel plate punching, and porous plate procumbent, can meet the demand for high-end customers.

2.Product characteristic:

Stainless steel raw materials after grinding and polishing the surface of the stainless steel plate with a specular gloss, there are BA, 2B, ordinary, 8K, 8K surface best

Uses: mainly used in building decoration, elevator decoration. Decoration, decoration and other industrial facilities, stainless steel series products. 316 stainless steel mirror, 316L stainless steel mirror, 304 stainless steel mirror, 301 stainless steel mirror, 201 stainless steel mirror, etc.

3.Specification:

1, by thickness classification

(1) plate (2) plate (3) plate (4) thick plate

2, according to the production method classification

(1) hot rolled sheet (2) cold rolled

3, according to the surface feature classification

(1) a galvanized sheet (2) () clad sheet (4) of a galvanized sheet (3) coated steel plate

4, by classification of uses

(1) bridge plate (2) boiler plate (3) shipbuilding plate (4) armor plate (5) automobile steel plate (6) roof plate (7) structural steel plate (8) electrical steel sheet (sheet) (9) spring plate (10) other, ordinary and mechanical structure with steel plate in common Japanese brand

4.Reference pictures:

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- You could, but if you have access to a vibrating case tumbler, it would work much better. I just tumbled a batch of 1,000 of tarnished and dirty Romanian 7.62X25 and it now looks like brand new commercial ammo.

- Q: I have a belly button piercing and the metal is stainless steel.. I was wondering does it develop rust whenever you go shower and clean it? Can I still swim in the summer with it or do I have to take it out? What happens if I swim in the pool with it?

- No it won't rust. Just make sure to get the pool water out of the piercing when done at the pool. Just to avoid drying out the skin too much.

- Q: PLEASE PLEASE PLEASE!!!!!!!! HELP MEEEEEEEE!!!!!!! I need to know how can i prevent steel from rusting when it is exposed to water or salt water or vinegar. PLEASE TELL ME A LOT OF WAYS THAT I COULD PREVENT IT!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- cathodic protection

- Q: What are the different types of steel coil loading and unloading methods?

- There are various methods for loading and unloading steel coils, including overhead crane systems, coil lifters, coil hooks, C-hooks, coil tippers, and coil carriages. Each method is suited for different coil sizes, weights, and handling requirements.

- Q: What are the common uses of stainless steel coils?

- Stainless steel coils have various common uses in different industries. Some of the most common applications include manufacturing of kitchen appliances, automotive parts, construction materials, and medical equipment. Additionally, they are used in the production of pipes, tubes, and wire products, as well as in the food and beverage industry for processing and storage equipment.

- Q: this is for a school project due morrow can u please answerwhat are disadvantages of stainless steelplease also show were u got info ty

- Disadvantages of Stainless Steel: 1. High initial cost 2. Difficult to fabricate, or in other words, it is not as malleable as other metals, say iron, and hence if not fabricated properly, results in costly re-work. 3. Difficult to weld 4. High cost of polishing etc. i.e. adding finishing touches for the market. Also, for the record: Stainless steel does NOT rust. One of the advantages of it over other metals (steel and iron) are that it is rust-free. But of course, depending on the environment condition (E.g. long periods in a rainforest without use at all) it can rust....this is a very rare (and unfortunate) situation. ;)

- Q: What are the key players in the steel coil manufacturing industry?

- The key players in the steel coil manufacturing industry are typically large multinational companies that have significant market share and influence. Some of the prominent players in the industry include: 1. ArcelorMittal: As the world's largest steel producer, ArcelorMittal is a major player in the steel coil manufacturing industry. They operate in more than 60 countries and have a diversified product portfolio. 2. Nippon Steel Corporation: Nippon Steel is a leading Japanese steelmaker and one of the largest steel coil manufacturers globally. They have a strong presence in automotive and construction sectors. 3. POSCO: Based in South Korea, POSCO is a major player in the steel industry, including steel coil manufacturing. They are known for their high-quality products and advanced technology. 4. Baosteel Group Corporation: Baosteel is the largest steelmaker in China and one of the largest globally. They have a wide range of steel products, including steel coils, and are known for their strong research and development capabilities. 5. Thyssenkrupp AG: Thyssenkrupp is a German multinational conglomerate with a significant presence in the steel coil manufacturing industry. They have a diverse product range and focus on innovation and sustainability. 6. United States Steel Corporation: As a leading American steel producer, United States Steel Corporation plays a crucial role in the steel coil manufacturing industry. They have a strong presence in the automotive, construction, and energy sectors. 7. JFE Holdings, Inc.: JFE Holdings is a Japanese steel conglomerate and one of the key players in the steel coil manufacturing industry. They have a wide range of steel products and are known for their quality and customer-oriented approach. These are just a few of the key players in the steel coil manufacturing industry, and there are many other companies that contribute to this sector. The industry is highly competitive, and these companies continuously strive to innovate, improve efficiency, and meet the ever-evolving demands of the market.

- Q: How are steel coils used in the manufacturing of machinery?

- Steel coils are used in the manufacturing of machinery as they provide a reliable and durable material for various components and structures. These coils are often shaped, cut, and formed into desired parts such as gears, shafts, frames, and supports. The high strength and versatility of steel coils allow them to withstand heavy loads and harsh conditions, ensuring the machinery's efficiency and longevity.

- Q: How are steel coils inspected for elongation?

- Steel coils are typically inspected for elongation by conducting a tensile test. A small sample is cut from the coil and subjected to tension until it breaks. The elongation is then calculated by measuring the increase in length of the sample at the point of fracture.

- Q: What are the different methods of forming steel coils into sheets?

- There are several methods of forming steel coils into sheets, including hot rolling, cold rolling, and annealing. Hot rolling involves heating the steel coils and passing them through a series of rollers to reduce their thickness and shape them into sheets. Cold rolling, on the other hand, does not involve heating the coils and instead uses pressure to shape them into sheets, resulting in a smoother and more precise finish. Annealing is a process that involves heating the steel coils to a specific temperature and then slowly cooling them, which helps to relieve stress and improve the material's ductility before it is formed into sheets.

Send your message to us

304 Stainless Steel Sheet ,Deep Drawing Board ,Wire Drawing Board ,Mirror Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords