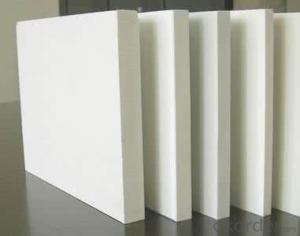

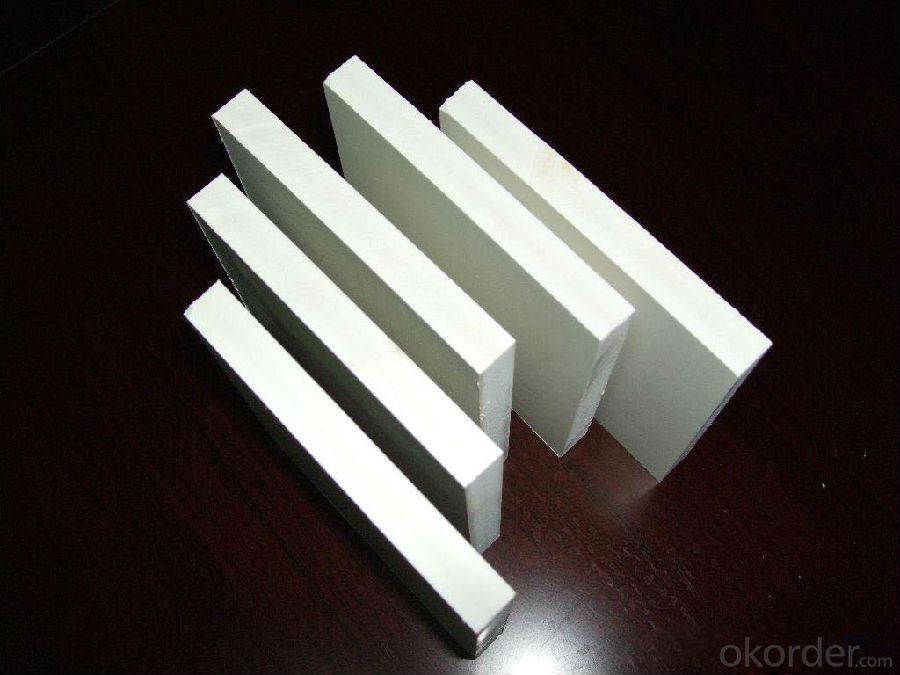

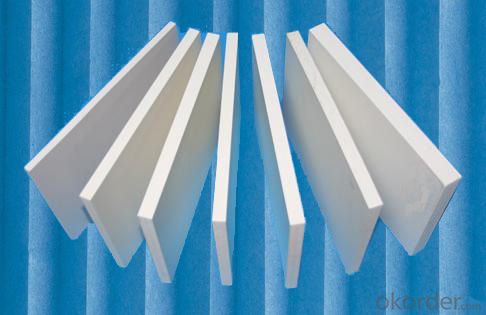

25mm White PVC Foam Skirting Board/Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

High density polyethylene price .

1. good quality

2. virgin material

3. high performance

4. excellent hardness

Product Description

Weldable/Bendable - suitable for fabrication

UV Resistant - Black only

Physiologically inert - approved for food applications (Natural only)

Electrical insulation - it is a good insulator

Weatherproof - it doesn't absorb water

Chemical resistance - resists corrosive chemicals (e.g. Sulphuric Acid, Caustic Soda)

Application:

Sheet is widely used in tank building and container building, waste water chemcial porcess inductry. For food Industry the cutting boards, Butcher Preparation table etc.

Products we offer, as following

1. Sheets

| Thickness(mm) | Length X width(mm) | Color | Minimum order | Density(g/cm3) |

| 2-100mm | 1200X2400mm, or1000mm | White, black or as required | 500KG | 0.96-0.98 |

Product pics:

2. Rods/ Bar

| Diameter(mm) | Length(m) | Color | Minimum order | Density(g/cm3) |

| 10-300mm | 1000mm or as required | White, black or as required | 500KG | 0.98 |

FAQ:

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities, they are mainly famous ,

such as USA, AUSTRILA, CANADA,EUROPE ,MIDDLE EAST,SOUTHEAST ASIA AND SO ON.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q2: Could you provide samples?

A2: Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

Q3: Is free design assistance available for clients?

A3: If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.

- Q: How do plastic sheets compare to PVC sheets?

- Plastic sheets and PVC sheets are very similar in nature as PVC is a type of plastic. However, PVC sheets specifically refer to sheets made from polyvinyl chloride, which is a durable and versatile type of plastic. PVC sheets have unique properties such as excellent chemical resistance, high impact strength, and flame retardancy, making them suitable for a wide range of applications, including construction, signage, and electronics. Therefore, while plastic sheets can be made from various materials, PVC sheets offer specific advantages due to their inherent properties.

- Q: Can plastic sheets be used for mold-making in manufacturing?

- Yes, plastic sheets can be used for mold-making in manufacturing. Plastic sheets are commonly used as mold-making materials due to their ability to be easily shaped, their durability, and their cost-effectiveness. They can be heated and molded into the desired shape, allowing for the creation of complex molds. Additionally, plastic sheets are resistant to many chemicals and can withstand high temperatures, making them suitable for various manufacturing processes.

- Q: Anyone used these? I want to try them. . .but just do not understand if they actually work as good as THEY say. These are the plastic or rubber ones that are suppose to be the thing now. . .

- they are made of silicone. Silicone has a very high burning and melting temperature, and nothing will stick to it, making it a perfect substance to use in kitchens.

- Q: Are plastic sheets resistant to warping or bending with heavy loads?

- Yes, plastic sheets are generally resistant to warping or bending under heavy loads, as they have a high tensile strength and are designed to maintain their shape and structural integrity even when subjected to significant pressure or weight.

- Q: What are the different sizes available for plastic sheets?

- Plastic sheets are available in a wide range of sizes, ranging from small sheets that are a few inches in length and width to large sheets that can be several feet long and wide. The specific sizes available will depend on the manufacturer and the intended use of the plastic sheet.

- Q: Can plastic sheets be used for signs and banners?

- Yes, plastic sheets can be used for signs and banners.

- Q: Can plastic sheets be used for lining ponds?

- Yes, plastic sheets can be used for lining ponds. These sheets, often made of heavy-duty polyethylene or PVC, are commonly used as pond liners to prevent water leakage and maintain the desired water level. They are easy to install, cost-effective, and provide a reliable barrier against seepage.

- Q: What are the different surface treatments available for plastic sheets?

- There are several surface treatments available for plastic sheets, including: 1. Coating: Plastic sheets can be coated with various materials like acrylic or polyurethane to enhance their appearance, provide added protection against scratches, and improve chemical resistance. 2. Laminating: Lamination involves applying a thin layer of plastic film onto the surface of the sheet, which can provide additional strength, durability, and resistance to moisture, UV radiation, and chemicals. 3. Printing: Plastic sheets can be printed with designs, logos, or patterns using techniques like screen printing, digital printing, or offset printing, allowing for customization and branding opportunities. 4. Embossing: This treatment creates a textured or raised pattern on the surface of the plastic sheet, adding a tactile dimension and aesthetic appeal. 5. Etching: Etching involves chemically or mechanically altering the surface of the plastic sheet to create a matte or frosted appearance, reducing glare and improving light diffusion. 6. Varnishing: Applying a clear varnish to plastic sheets can provide a glossy finish, enhancing the visual appeal and protecting the surface from scratches and abrasion. These surface treatments offer a range of benefits, allowing plastic sheets to meet specific functional and aesthetic requirements in various industries such as automotive, packaging, construction, and signage.

- Q: I am making a craft project. I went to a craft store and purchased a yard of plastic in the fabric dept. I cut two 6X6 pieces and glued them with a water resistant glue. I allowed 24hrs. I then put water inside and a few hrs later noticed it was soaking through the plastic and leaking. I need a glue that will hold water inside. I hope this clarifies my question.

- Water resistant normally does not include immersion. It depends on the plastic. And fabric department through the plastic bother me - is the plastic itself water tight? If you make a bag of a square by holding up the 4 corners and pouring water in the sag, does water drip through? As a starting point, I would suggest looking on the packaging for E6000 and GOOP products (from the same company) and see whether they are okay for immersion in water. I use them outside, but don't recall. You may have to fold the seam and apply the glue to hold the seam so the water only touches the glue at a thin line. Aquarium silicone glue should work, but it won't stick to some plastics. I am not sure acrylic sheet comes as thin as you want and PVC has to be opaque, I believe, but both use a solvent cement that partially melts the plastic then evaporates. If the plastic is thermoplastic - it melts when heated - then you can seal the seams with an iron. Check a small piece of the plastic over a match or kitchen burner - the difference between melting and burning should be obvious.

- Q: How are plastic sheets made?

- Plastic sheets are typically made through a process called extrusion, where melted plastic is forced through a die to form a continuous sheet. The plastic pellets are first melted and then fed into a heated barrel, where they are forced through a rotating screw. The molten plastic is then pushed through a flat die, which determines the thickness and width of the sheet. As the plastic exits the die, it is cooled and solidified using either air, water, or a combination of both. The resulting plastic sheet can be cut and shaped according to specific requirements.

Send your message to us

25mm White PVC Foam Skirting Board/Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords