20x40mm Aluminum Profiles for Electric Power Engineering Sector

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminum Extrusion for Electric Power Engineering Sector Description

Aluminum Extrusion for Electric Power Engineering Sector is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminum Extrusion for Electric Power Engineering Sector

Aluminum Extrusion for Electric Power Engineering Sector | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminum Extrusion for Electric Power Engineering Sector

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminum Extrusion for Electric Power Engineering Sector

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminum Extrusion for Electric Power Engineering Sector

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

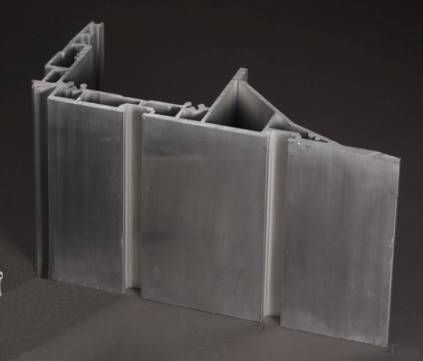

6. Image of Aluminum Extrusion for Electric Power Engineering Sector

7. Package and shipping of Aluminum Extrusion for Electric Power Engineering Sector

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum profiles suitable for lighting fixtures?

- Yes, aluminum profiles are highly suitable for lighting fixtures. Aluminum is a versatile and lightweight material that offers several advantages for lighting applications. Firstly, aluminum profiles have excellent thermal conductivity, which means they effectively dissipate heat generated by the lighting fixtures. This is crucial as excessive heat can reduce the lifespan of the lighting components and affect their performance. Aluminum profiles help to maintain a cooler operating temperature, thereby enhancing the longevity and efficiency of the lighting fixtures. Secondly, aluminum profiles are corrosion-resistant, making them suitable for indoor and outdoor lighting fixtures. This resistance to corrosion ensures that the fixtures can withstand harsh environmental conditions, such as high humidity or exposure to moisture, without deteriorating or losing their functionality. Furthermore, aluminum profiles are easily customizable and can be designed to accommodate various lighting requirements. They can be extruded into different shapes and sizes, allowing for flexibility in the design of lighting fixtures. This versatility enables manufacturers to create sleek and modern lighting solutions that can be seamlessly integrated into different spaces and architectural designs. In addition, aluminum profiles offer aesthetic appeal as they can be powder-coated or anodized in various colors, providing a wide range of options to match different interior or exterior design themes. Lastly, aluminum is a sustainable material that is fully recyclable. Opting for aluminum profiles in lighting fixtures contributes to reducing environmental impact and supports the principles of sustainability. Overall, due to their thermal conductivity, corrosion resistance, versatility, aesthetic appeal, and sustainability, aluminum profiles are highly suitable for lighting fixtures and are widely used in the lighting industry.

- Q: What are the different finishing options available for aluminum profiles?

- To enhance the appearance and provide extra protection, aluminum profiles offer a range of finishing options. These options can be divided into two main categories: surface treatments and coatings. Surface treatments encompass anodizing, powder coating, and polishing. Anodizing, a widely used technique, involves creating a durable and corrosion-resistant layer on the aluminum surface through an electrochemical process. This method offers various colors and finishes while preserving the metallic look. Powder coating, on the other hand, entails applying a dry powder to the aluminum surface and then curing it with heat, resulting in a smooth and long-lasting finish. For a reflective and glossy appearance, polishing is an alternative that involves mechanically smoothing the aluminum surface. Coatings, however, involve the application of a protective layer on the aluminum. These coatings can be either organic or inorganic. Organic coatings, such as paint or lacquer, provide a decorative finish and safeguard the surface against scratches and oxidation. In contrast, inorganic coatings like ceramic or enamel offer superior durability and resistance to abrasion, heat, and chemicals. Furthermore, mechanical finishing processes like brushing or sandblasting can be applied to aluminum profiles. Brushing creates a textured finish by using abrasive brushes to form a pattern on the surface. Sandblasting, on the other hand, roughens the surface by forcefully propelling fine particles at high speed, resulting in a matte appearance. Choosing the appropriate finishing option for aluminum profiles depends on factors such as the intended application, aesthetic preference, and desired level of protection. Each option has its own advantages and disadvantages, so it is crucial to consider factors like durability, maintenance, and cost before making a selection.

- Q: This question asks for methods to prevent corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion of aluminum profiles during installation, follow these steps: 1. Use stainless steel fasteners and avoid galvanized or carbon steel screws which can cause galvanic corrosion. 2. Keep the aluminum profiles clean and dry during installation to avoid contact with moisture which can initiate corrosion. 3. Apply a protective coating or sealant to the profiles, especially at cut edges where the protective oxide layer may be compromised. 4. Store aluminum profiles in a dry, cool place before installation to prevent moisture absorption. 5. Regularly inspect and maintain the profiles to identify and address any signs of corrosion early. By adhering to these practices, you can significantly reduce the risk of corrosion on aluminum profiles during installation.</p>

- Q: Are aluminum profiles suitable for use in automotive engine components?

- Yes, aluminum profiles are suitable for use in automotive engine components. Aluminum is lightweight, which helps improve fuel efficiency and reduce emissions. It also has good heat conductivity, allowing for efficient heat dissipation in engine components. Additionally, aluminum profiles offer excellent strength and durability, making them suitable for withstanding the demanding conditions of an automotive engine.

- Q: Are there any specific cleaning and maintenance instructions for aluminum profiles?

- Yes, there are specific cleaning and maintenance instructions for aluminum profiles. Here are a few guidelines to follow: 1. Regular cleaning: Aluminum profiles should be regularly cleaned to maintain their appearance and prevent corrosion. Use a mild soap or detergent mixed with water to clean the surface. Avoid using abrasive cleaners or steel wool as they can scratch the aluminum. 2. Avoid harsh chemicals: Harsh chemicals can damage the protective coating on the aluminum profiles. Avoid using strong acids, alkaline cleaners, or solvents for cleaning purposes. 3. Rinse thoroughly: After cleaning, make sure to rinse the aluminum profiles thoroughly with clean water. This will remove any residue from the cleaning solution and prevent streaking. 4. Dry thoroughly: After rinsing, dry the aluminum profiles completely using a soft cloth or towel. Moisture left on the surface can lead to corrosion, so it's important to ensure the profiles are completely dry. 5. Lubrication: If the aluminum profiles have moving parts or hinges, it's recommended to lubricate them regularly to ensure smooth operation. Use a lubricant specifically designed for aluminum to avoid any adverse effects. 6. Protective coatings: Some aluminum profiles come with protective coatings, such as anodized or powder-coated finishes. These coatings provide an extra layer of protection against corrosion and should be maintained as per the manufacturer's instructions. 7. Avoid abrasive cleaning tools: When cleaning aluminum profiles, avoid using abrasive cleaning tools such as brushes or scouring pads. These can scratch the surface and damage the protective coating. It's important to note that specific cleaning and maintenance instructions may vary depending on the type and finish of the aluminum profiles. Therefore, it's always advisable to refer to the manufacturer's guidelines for the best cleaning and maintenance practices for your specific aluminum profiles.

- Q: How do aluminum profiles contribute to water management strategies?

- Aluminum profiles play a crucial role in water management strategies due to their inherent properties and versatility. These profiles are commonly used in the construction of various water management infrastructure such as pipes, channels, and tanks, among others. Firstly, aluminum profiles are lightweight yet sturdy, making them ideal for constructing water pipes. Their lightweight nature allows for easy transportation and installation, while their strength ensures durability and resistance to corrosion. This is particularly important in water management systems as it reduces the risk of leaks and damages, ensuring the efficient and effective transport of water resources. Secondly, aluminum profiles are highly resistant to corrosion. Corrosion is a major concern in water management as it can contaminate water, reduce its quality, and damage infrastructure. By utilizing aluminum profiles, the risk of corrosion is significantly reduced, leading to improved water quality and longevity of the infrastructure. Additionally, aluminum profiles are highly customizable and can be fabricated into various shapes and sizes, allowing for the creation of efficient water management systems. These profiles can be used to construct channels, culverts, and tanks, which are crucial components of water management infrastructure. The versatility of aluminum profiles enables engineers and designers to create efficient and effective systems that can handle large volumes of water, ensuring proper water management in various scenarios such as irrigation, flood control, and wastewater treatment. Moreover, aluminum is a sustainable material that can be recycled indefinitely without losing its properties. This makes aluminum profiles an environmentally friendly choice, aligning with sustainable water management practices. By using aluminum profiles, water management strategies can minimize their environmental impact and contribute to a more sustainable future. In summary, aluminum profiles have a significant impact on water management strategies. Their lightweight yet sturdy nature, corrosion resistance, versatility, and sustainability make them indispensable in the construction of water management infrastructure. By utilizing these profiles, water management systems can be built to efficiently and effectively handle water resources, reducing the risk of contamination, improving water quality, and promoting sustainability.

- Q: Can aluminum profiles be used in agricultural machinery manufacturing?

- Yes, aluminum profiles can be used in agricultural machinery manufacturing. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it suitable for various components such as frames, brackets, and structural parts in agricultural machinery. Its versatility also allows for customization and easy integration with other materials, contributing to the overall efficiency and performance of the machinery.

- Q: What are the different types of gaskets used with aluminum profiles?

- Aluminum profiles commonly utilize various types of gaskets. Let's explore a few examples: 1. EPDM Gaskets: Crafted from a synthetic rubber material, EPDM gaskets excel in withstanding weathering, UV radiation, and ozone exposure. They are frequently employed in outdoor scenarios that demand a secure seal and resilience against harsh environmental conditions. 2. Silicone Gaskets: Renowned for their exceptional temperature resistance, silicone gaskets are a preferred option for applications involving extreme heat or cold. They also exhibit favorable resistance to chemicals and UV radiation, rendering them suitable for a wide array of industrial and commercial uses. 3. PVC Gaskets: Composed of a plastic material, PVC gaskets are extensively used due to their remarkable resistance to chemicals, oil, and moisture. They commonly find application in situations necessitating a tight seal, such as doors, windows, and architectural uses. 4. Neoprene Gaskets: Neoprene gaskets are constructed from a synthetic rubber material that offers commendable resistance to oils, chemicals, and weathering. They are frequently employed in machinery and equipment, where both sealing and vibration dampening are required. 5. Nitrile Gaskets: Nitrile gaskets, also known as Buna-N gaskets, are composed of a synthetic rubber material that boasts outstanding resistance to oils, fuels, and solvents. They find common use in automotive and industrial settings where resistance to oil and fuel is critical. These examples are merely a snapshot of the diverse gasket options available for aluminum profiles. The choice of gasket hinges upon the specific requirements of the application, encompassing desired sealing level, environmental conditions, and chemical compatibility.

- Q: Can aluminum profiles be used for creating display systems?

- Yes, aluminum profiles can be used for creating display systems. Aluminum is a versatile and lightweight material that is widely used in various industries, including the display and signage industry. Aluminum profiles offer several advantages for creating display systems. Firstly, aluminum is highly durable and corrosion-resistant, making it suitable for both indoor and outdoor display applications. It can withstand various environmental conditions, ensuring the longevity of the display system. Secondly, aluminum profiles are easily customizable. They can be extruded into various shapes and sizes, allowing for flexibility in design. This makes it possible to create unique and eye-catching display systems that meet specific requirements. Additionally, aluminum profiles are easy to assemble and disassemble, which is beneficial for display systems that require frequent changes or transportability. They often come with a simple slot and groove system or other connecting mechanisms, making installation and maintenance hassle-free. Moreover, aluminum profiles can be anodized or powder-coated to provide a decorative or protective finish. This allows for customization in terms of color and texture, enhancing the aesthetics of the display system. Lastly, aluminum profiles provide structural stability while remaining lightweight. This makes them suitable for large-scale displays or installations where weight is a concern. In summary, aluminum profiles are an excellent choice for creating display systems due to their durability, customizability, ease of assembly, and aesthetic appeal.

- Q: How do you calculate the strength of aluminum profiles?

- In order to determine the strength of aluminum profiles, there are several factors that must be taken into account. Firstly, it is necessary to gather information about the mechanical properties of the aluminum alloy being used, such as its yield strength, ultimate tensile strength, and elastic modulus. This data can be obtained from material data sheets or through testing. Next, the cross-sectional area of the aluminum profile needs to be determined. This can be achieved by measuring the profile's dimensions or referring to its specifications. Generally, the cross-sectional area is calculated by multiplying the profile's width and height. Once the cross-sectional area is known, the applied load on the profile can be calculated. This involves considering the weight or force that will be exerted on the profile. It is important to account for any potential variations or impacts, as the load can be either static or dynamic. With the load and cross-sectional area determined, the stress on the aluminum profile can be calculated using the formula: Stress = Load / Cross-sectional area. This will provide the stress value in units of force per unit area, such as N/m2 or psi. To ensure that the profile's strength is sufficient, a safety factor is typically applied. This accounts for uncertainties in the load calculations and guarantees that the profile can withstand unexpected loads or variations. The magnitude of the safety factor may vary depending on the specific application and industry standards, ranging from 1.5 to 4. By considering these factors and performing the necessary calculations, it is possible to ascertain the strength of aluminum profiles and ensure that they meet the required safety standards for their intended applications.

Send your message to us

20x40mm Aluminum Profiles for Electric Power Engineering Sector

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords