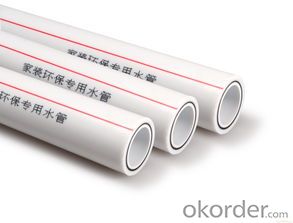

2024 New China Plastic Tubes PP-R Pipes for Industrial Application

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Overview

Place of Origin: Henan, China (Mainland)

Model Number: PE100

Material: PE

Specification: DN 20-mm~DN1200mm

Length: According to customer requirement

Thickness:SDR11/13.6/17

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Name: HDPE Plastic Pipe

Application

1) Cold and hot water systems of residence and commercial buildings

2) Transportation of industrial water supply and chemical materials

3) Pure water pipe system

4) Piping networks for rainwater utilization systems

5) Irrigation agriculture and horticulture systems

6) Transportation system of drinking water production

7) Piping networks for solar plants

8) Other pipes in industry

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

Main Product Features:

Large drum hub to maximize cable life

Self-activating automatic brake hold the load securely when crank handle is released

With cable or strap

Safety guard cover available

Top quality with competitive price

Widely used in the double beam bridge crane and gantry crane

Easy to install and high quality

Compact structure and reasonable design

Could be mounted on t he ground or wall!

Double drum!!

- Q: What's the diameter of the white plastic tube in the kitchen, about 10cm? What should I do if the water leaks?

- Electrode welding: buy several PVC welding electrodes to the building materials shop or hardware city, and weld the welding rod to dew point with hot blast welding torch.The above two methods must first wipe the dew point, no water, and within 12 hours after the repair and repair, the water pipe shall not be used.

- Q: Can plastic tubes be used for plumbing?

- Yes, plastic tubes can be used for plumbing. Plastic pipes, such as PVC (polyvinyl chloride) and PEX (cross-linked polyethylene), are commonly used in plumbing systems for their durability, affordability, and ease of installation. They are resistant to corrosion, have good chemical compatibility, and offer flexibility in design and installation options.

- Q: The babies are 5 days old and we haven't touched them yet. I read that the plastic tubes were bad for the babies ventilation but im afraid if we move them that she will eat them. She built the nest in one of the circles that stands upright. what do i do?

- don't Touch them and get the mom away and win they open there eyes you can move them but make shure the lid is open so they can breath

- Q: We're adopting a six-month-old kitten soon, and she's a good fit in with our family except she's a chewer. My grandma is on oxygen and her tube snakes through our upstairs hallway. Although the cat won't be upstairs much, is there any way to make her NOT want to chew it? Wrapping it in something isn't a good idea, as my grandma is still sort of mobile and has to make it to the bathroom and such, but is there any kind of spray or powder you can put on a plastic tube that cats hate?Thanks!

- I heard if you put Vicks Vapor rub on wires they wont chew it. so maybe it will work for you. It wont make them sick either.

- Q: Can plastic tubes be used for packaging cosmetics?

- Yes, plastic tubes can be used for packaging cosmetics. They are commonly used for various cosmetic products such as creams, lotions, gels, and lip balms due to their flexibility, durability, and ability to protect the product from contamination and air exposure.

- Q: How do plastic tubes perform in acidic environments?

- Plastic tubes generally perform well in acidic environments, as they are resistant to corrosion and degradation caused by acids. However, the specific performance can vary depending on the type of plastic used. Some plastics may have higher resistance to acids than others, so it is important to choose the appropriate plastic material for the specific acidic environment.

- Q: I need to clean my gravel and have read a bunch of reveiws on the gravel cleaning syphons and I don't want to waste my money on a cleaner that doesnt work. I might not be using the correct term for the product, it is one of those tubes that you shake to create a syphon. Thanks for all your help

- I use the Python no-spill siphon. It works very well.

- Q: Are plastic tubes suitable for vacuum applications?

- Plastic tubes can be suitable for vacuum applications depending on the specific requirements and conditions. Some plastic materials, such as PVC or polyethylene, may not be able to maintain a strong vacuum due to their inherent permeability to gases. However, other plastic materials, like nylon or PTFE, offer better resistance to gas permeation and can be used effectively in vacuum systems. Additionally, the design and construction of the plastic tube, including its wall thickness and reinforcement, play a crucial role in determining its suitability for vacuum applications. Ultimately, it is important to consider the specific needs of the vacuum system and consult with experts to select the most appropriate materials and design for the intended application.

- Q: How can PE plastic pipe be welded with PVC plastic?

- Merely connected with small diameter, large diameter flange connection.

- Q: im looking for a place to buy a small piece of latex tubing maybe about a foot long. i checked local pharmacy and drug stores with no luck. any other suggestions?

- Try Lowe's or Home Depot. I used vinyl tubing from Lowe's to fix my sink. I think they sell latex tubing as well.

Send your message to us

2024 New China Plastic Tubes PP-R Pipes for Industrial Application

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords