2015 Hot Dipped Wire High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 250000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.2015 High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years Description:

Galvanized Iron Wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.

Galvanized Iron Wire mainly used in construction, express way fencing, binding of flowers and wire mesh weaving. Galvanized iron wire according to manufacturing technique, it includes hot-dipped galvanized iron wire and electro galvanized iron wire. Mainly telecommunication equipment and materials, medical equipment and device, weaving of wire mesh, steel rope, and filtration mesh, high-pressure pipe, construction, arts and crafts.

2.Main Features of 2015 High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years :

• Use widely

• Corrosion- resistant

• Durable

• Practical use

• Beauty Surface

• Versatile

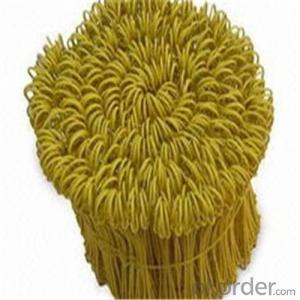

3. 2015 High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years Images

4.2015 High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your 2015 High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information of 2015 High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years ?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

CNBM Hot Dipped Zinc Coating Iron Wire Own Factory for 0.3mm to 7mm

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served。

2015 High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years

2015 High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years

- Q: A long horizontal wire carries a current of = 52 . A second wire, made of 1.00--diameter copper wire and parallel to the first, is kept in suspension magnetically 5.0 below.What is the magnitude of the current in the lower wire?

- The lower wire is kept in suspension magnetically means that the downward force of gravity is equal to the upward magnetic force. Its NOT an easy problem so we need to solve it in small steps. Let's find the two forces acting on the lower wire: (*) Downward force of gravity = mg = (volume) x (density) x (gravitational acceleration) = (pi r^2 L) x(8920)x(9.8) = 0.06896L We assume the radius of the wire is 0.5 mm or 0.0005m, copper density is 8960 N/m^3, gravitational acceleration = 9.8 m/s^2 (**) Upward magnetic force = mu(zero) x i(one) x i(two) x L / (2 pi d) = 2.08x10^(-4) L i(two) mu(zero) is a constant = 4 pi 10^(-7), i(one) is the current in the first wire = 52A, i(two) is the unknown current in the second wire, d is the distance between the wires = 5 mm or 0.005m The forces are equal, therefore 0.06896L = 2.08x10^(-4) L i(two) We divide both sides by L (the unknown length of the lower wire) and now we can solve for the current i(two) ANSWER: i(two) = 331.5 A

- Q: hello,i have lots of 8 gauge wire resting at my closet. And i'm very interested on doing the big 3 upgrade to my 2000 mitsubishi eclipse gt. May i see any improvement with 8 gauge wire?...i know that at least 4 gauge is recommended...but i dont want to spend money.

- 4 gauge? LOL Go big or go home. 1/0 gauge or it didn't happen.

- Q: I want to install a single-pole dimmer switch for a series of 4 pot lights in the same box (double gang) as a kill switch for a receptical already installed. There is a 14-3 wire (b/w/r/g) brigning power into the box from the main, and 14-2 wiring for the dimmer and 14-2 wire for the kill switch. How do I wire this? The single pole dimmer has a ground and two black wires. The switch to kill the receptical has only two brass screws on one side.

- Before you go cutting any wires, please verify what each is to/for. I am concerned that the 14-3 is not the incoming from the panel. There is a chance for 2 other possibilities: 1) The power is fed from the light fixture (using the 14-3). If this is the case, the black will be the constant hot and the red will be the switched power returning to the fixture. 2) The 14-3 is actually the wire to the receptacle for a half-hot (half switched receptacle). If I am wrong, then so be it. If I am correct it will totally change how this gets connected. If you have already cut that red wire, you'll be regretting it.

- Q: where does the expression 'down to the wire', come from?

- I found this online: The wire is used in a four-legged footrace-- at least I've only ever heard the word tape used for races involving bipeds. That and ribbon. The wire in question is an actual wire, and it's used in the Sport of Kings, horseracing. A tape or ribbon would be too stretchy to instantaneously trip the shutter on the finishing-line camera when it was crossed. A horse has no problem busting through a single strand of wire.

- Q: I am installing a GFCI outlet in the kitchen (20 AMP) the box that it is already installed in has more than nine wires running into it. What I need to know is how does one determine the load wires from line wires when there are multiple wires running to an outlet box?

- You use some test equipment to determine which is the line cable. All of the grounds are connected together. Identify each of the remaining wires with numbers BEFORE you disconnect anything. After that you can make a wiring drawing of the connection box and device before you disconnect anything. Once the drawing is done you can tun off the circuit(s) and begin the changes. The line/hot wire and it's neutral are connected to the G F I line connections, the load connections are made to protect any down line devices. If you do not need to protect the down line devices all of the connections can be made before the G F I device. If this seems too much of a challenge for you the best solution is to have a qualified professional electrician do the work.

- Q: my dogs have chewed my central air contactor wire.my ac will not cut on. does anyone knows how to replace them and where to buy replacement wires locally( i live in Dallas TX.) i would like to do it myself instead of spending a lot of money.

- You shouldn't need to replace the wires, only splice them back together, color to like color. If you decide to replace them, they are 18 gauge. Depending on the unit that you have, there may be 2, 3, 5, 7, or 9 wires. Install the wire in 3/8 flex to prevent a repeat. Lowes and Home Depot will sell you the wire by the lenght you need. Ask for jacketed wire.

- Q: (a) A copper wire and an iron wire have the same length and same diameter and carry same current I. In which wire is the electric field greater?(b) Can a 1mm in diameter copper wire have the same resistance as a tungsten wire of the same length?[Use p(copper)=1.7x10^-8 ohm meters, p(iron)=1x10^-8 ohm meters, p(tungsten)=5.6x10^-8 ohm meters]

- a Since copper has higher resistivity than iron, the voltage drop in the copper wire with the same dimensions as the iron wire is greater, meaning more Volts/meter in the copper wire so the E field is greater in the copper wire. b Resistance is proportional to length, resistivity, and inversely proportional to diameter. Increasing the diameter could compensate for a material with higher resistivity. So the answer is yes.

- Q: how do i wire my sensor to my light

- Normally it is black wire to black wire, white to white and ground (copper) to ground.

- Q: i have until November 24 to choose between a wire or plastic retainer for when i get my braces off.In your answer please say why you would choose a wire or plastic retainer.

- I actually have a sparkling invisiline retainer and prefer it. I sparkling it two times an afternoon in pepsodent (using chilly water, no longer warm). I on no account consume with the retainer--I consistently do away with it as quickly as I consume--and when I consume, I brush my tooth and then brush/rinse the retainer. I do the pepsodent soakings two times an afternoon--morning and at night. I used Efferdent till now each and everything, yet that took too long--30-40 5 minutes. Pepsodent works in approximately 3 minutes. I save a broom with the Pepsodent and use it to scrub the answer out of the recesses of the retainer. that's in simple terms a habit now--in case you do this, your retainer will stay vivid and sparkling. No stinkiness. (And my orthodontist stated that Efferdent --no longer the blue-staining varieties--and Pepsodent artwork in simple terms besides as Retainer Brite. that's much less annoying to locate Pepsodent Efferedent besides. reliable success.

- Q: I have a 300 watt pioneer home stereo and four 15speakers that are250 watts each would it be ok to use this wire i just bought here is the link was wanting to know if it was ok to use if it seas car stereo wire thanks

- yeah thats fine they will work. do suggest some monster speaker cable over that but what you have there in the link will work.

Send your message to us

2015 Hot Dipped Wire High Zinc Coating Hot Dipped Q195 Wire CNBM Factory for 30 Years

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 250000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches