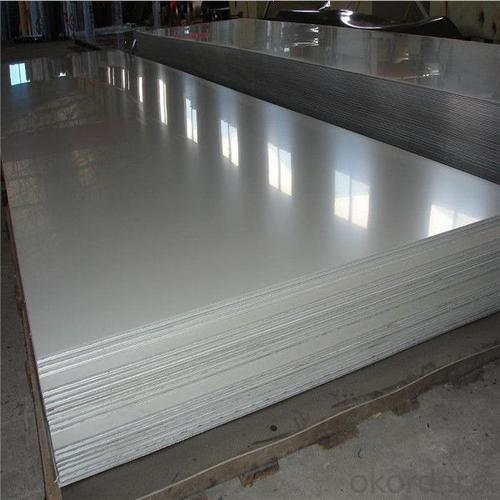

201 304 Stainless Steel Sheets TISCO LISCO ZPSS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

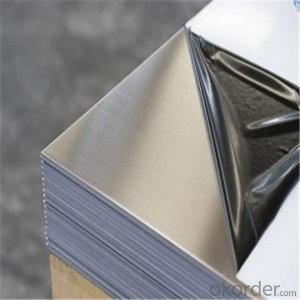

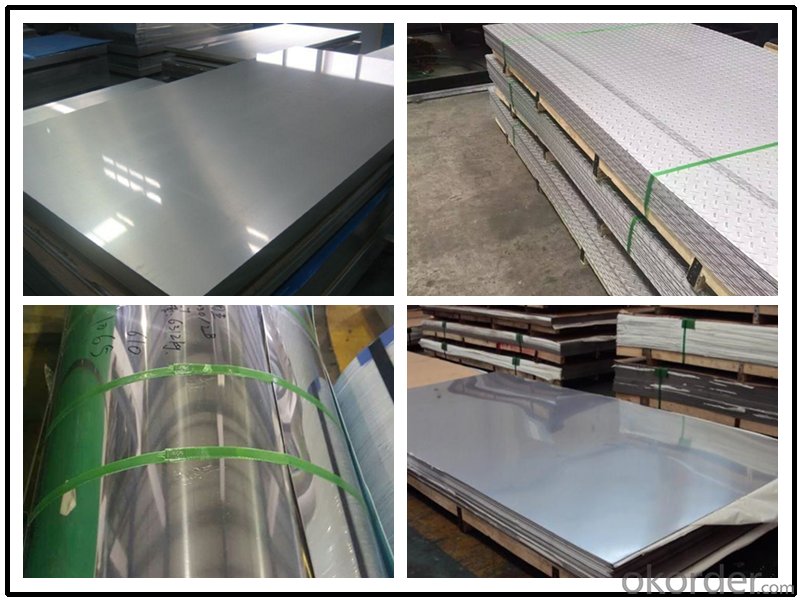

304 316 cold rolled stainless steel sheet

Standard:JIS,AISI,ASTM,GB,DIN,EN

Material:201,202,316,304,304L,316,316L,321,430,etc.

Thickness:0.5mm~2.0mm

Width: 1000mm~1250mm

Length:1000mm-6000mm or as your requirement

Finish:2B, BA, Hair Line, No.1,No.4, Mirror ,color,etching

Technique:cold rolled

Packaging & Shipping

Trade terms:

Packing: Standard export seaworthy packing with waterproof paper,metal belt pack sheet,then put them in wooden pallet(or put them in wooden case),then put them in container or as customer's requirement.

MOQ: 5 metric tons

Shipping Term: FOB GUANGDONG or CNF import port

Delivery Time: 15 to 35 days after the receipt of the deposit

Payment Term: T/T 30% deposit, Balance against the copy of B/L; or L/C at sight

201 304 cold rolled stainless steel sheets

Application

- Q: What's the difference between the 304 stainless steel plate and the 310S stainless steel plate?

- 304 stainless steel is a common stainless steel material, the density of 7.93 g/cm3, the industry is also called 18/8 stainless steel. High temperature resistance of 800 degrees, with good processability, high toughness characteristics, widely used in industry and furniture decoration industry and food and medical industry.

- Q: Can stainless steel sheets be used for beer tanks?

- Yes, stainless steel sheets can be used for beer tanks. Stainless steel is a commonly used material for beer tanks due to its durability, corrosion resistance, and ability to maintain the quality and taste of the beer. It provides a hygienic and easy-to-clean surface, making it ideal for use in the brewing industry.

- Q: How about stainless steel grades?

- According to the composition can be divided into Cr (400 Series), Cr Ni system (300 Series), Cr Mn Ni (200 Series) and the precipitation hardening systems (Series 600). 200 series - chromium nickel manganese austenitic stainless steel 300 series - chromium nickel austenitic stainless steel 301 - ductility, used for molding products. It can also be hardened rapidly by mechanical processing. Good weldability. The abrasion resistance and fatigue strength are better than 304 stainless steel. 302 - 304 with corrosion resistance, due to the relatively high carbon intensity. 303 - by adding a small amount of sulfur and phosphorus, it is easier to cut than 304.

- Q: Are stainless steel sheets suitable for oil and gas applications?

- Stainless steel sheets prove to be a suitable option for oil and gas applications. Renowned for their exceptional resistance to corrosion, stainless steel sheets are extremely well-suited for deployment in challenging environments, such as those encountered within the oil and gas industry. They can endure exposure to a wide array of corrosive substances, including acids, alkalis, and saltwater, without experiencing degradation or corrosion. Moreover, stainless steel boasts impressive strength and durability, rendering it capable of withstanding the high-pressure conditions typically encountered during oil and gas operations. Additionally, it exhibits resistance to elevated temperatures, which is particularly crucial in scenarios necessitating heat resistance. Furthermore, stainless steel sheets can be conveniently fabricated and molded to meet specific design requirements, thereby affording flexibility in engineering and construction endeavors. Overall, the blend of corrosion resistance, strength, and adaptability solidifies stainless steel sheets as an outstanding choice for employment in oil and gas applications.

- Q: What are the different types of surface treatments for stainless steel sheets?

- There are several types of surface treatments for stainless steel sheets, including brushing, grinding, polishing, and coating. Brushing creates a textured finish, grinding removes imperfections, polishing enhances shine, and coating adds a layer of protection.

- Q: Are stainless steel sheets resistant to UV rays?

- Yes, stainless steel sheets are resistant to UV rays. Stainless steel is known for its durability and corrosion resistance, and this extends to its ability to withstand exposure to UV rays. The chromium content in stainless steel forms a protective oxide layer on the surface, which helps prevent the metal from oxidizing or corroding when exposed to sunlight. This oxide layer acts as a barrier that shields the stainless steel from UV rays, making it highly resistant to the damaging effects of prolonged sun exposure. Therefore, stainless steel sheets are an excellent choice for outdoor applications where UV resistance is a requirement, such as roofing, cladding, and architectural elements.

- Q: How do I prevent corrosion under insulation on stainless steel sheets?

- To prevent corrosion under insulation on stainless steel sheets, there are several steps you can take: 1. Proper insulation selection: Choose insulation materials that are compatible with stainless steel and have a low water absorption rate. Avoid using materials that can cause galvanic corrosion when in contact with stainless steel. 2. Adequate insulation thickness: Ensure that the insulation thickness is sufficient to prevent moisture condensation on the stainless steel surface. Condensation can trap moisture and accelerate corrosion. Consult with an insulation specialist to determine the appropriate thickness for your specific application. 3. Vapor barriers: Install vapor barriers between the insulation and the stainless steel sheets. Vapor barriers act as a moisture barrier, preventing the ingress of water or moisture that can lead to corrosion. These barriers can be made of materials such as foil or plastic films. 4. Proper installation: Ensure that the insulation is properly installed, with no gaps or areas where moisture can accumulate. Pay close attention to joints, seams, and connections, making sure they are tightly sealed to prevent water penetration. 5. Regular inspection and maintenance: Regularly inspect the insulation system to identify any signs of damage, such as leaks or deterioration. Promptly repair any damaged insulation or vapor barriers to prevent moisture from reaching the stainless steel surface. 6. Ventilation: Provide adequate ventilation to prevent moisture buildup in enclosed spaces. Good airflow can help reduce the chances of condensation and subsequent corrosion. 7. Cathodic protection: Consider using cathodic protection methods, such as sacrificial anodes or impressed current systems, to protect stainless steel sheets from corrosion. These methods create an electrical current that counteracts the corrosion process, extending the lifespan of the stainless steel. Remember, it is essential to consult with corrosion specialists or insulation experts to ensure the best practices are implemented for your specific application and environment.

- Q: Can stainless steel sheets be used for magnetic shielding?

- Yes, stainless steel sheets can be used for magnetic shielding. Stainless steel has a high permeability, which means it can redirect and absorb magnetic fields, making it an effective material for shielding against magnetic interference.

- Q: What are the advantages and disadvantages of net drawing stainless steel users?

- Brushed stainless steel refers to: stainless steel surface like filamentous texture, this is only a stainless steel processing technology. The surface is Matt, and carefully look at the above there is a trace of texture, but can not touch it.

- Q: Stainless steel drawing plate, polishing plate, mirror panels of the three differences

- From the difference, the stainless steel wire drawing board is a long line, as it is covered with stainless steel plate. The polishing plate refers to a stainless steel plate with a certain brightness. The stainless steel mirror panels can be collectively referred to as glass like stainless steel mirror panels.

Send your message to us

201 304 Stainless Steel Sheets TISCO LISCO ZPSS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords